Using high-pressure cleaning equipment on residential exteriors often raises concerns regarding its effects on internal piping systems. My experience as a product expert in this field leads me to advise caution. While these machines are powerful tools for removing dirt and grime, they can inadvertently cause issues within plumbing layouts.

High-velocity water jets can force debris and sediment deeper into the pipes, potentially leading to blockages. Moreover, the sheer force can compromise aging or compromised sections, making them susceptible to leaks. For those with older systems or visible signs of wear, it is advisable to assess the integrity of the pipes beforehand. Investing in an assessment from a qualified plumber may save significant repair costs down the line.

Choosing the right nozzle and pressure setting is crucial. Use a lower setting and a wide-angle spray to minimise risks. Gentle cleaning may take slightly longer but can mitigate potential damage. Prioritising safety and maintenance ensures the longevity and efficiency of both your cleaning equipment and your home’s plumbing infrastructure.

Can a Pressure Washer Harm Your Pipes?

Using high-powered equipment for cleaning tasks can pose risks to your piping infrastructure. It’s vital to understand how certain conditions can lead to issues.

- Assess the material of your pipes. Older systems with materials like PVC or galvanised steel may not withstand intense water force.

- Check for existing weaknesses. If there are pre-existing leaks or corrosion, the water pressure can exacerbate these problems significantly.

- Limit the use of high settings. Excessive force can dislodge joints or fittings, leading to possible ruptures.

- Use appropriate accessories. Opt for nozzles that deliver a gentler spray for tasks near plumbing connections.

Testing on non-critical areas before full application can help gauge the impact on your system. Regular inspections of your water lines will ensure you’re aware of their condition before undertaking any cleaning activities.

Investing in a model with adjustable pressure settings allows for safer operation and minimises the chance of accidental harm to your fixtures.

Always prioritise proper technique. When in doubt, consult a professional to assess your specific situation and recommend the best course of action to preserve your infrastructure.

Understanding Pressure Washer Functionality

For optimal performance, always identify the appropriate nozzle for your specific task. The selection significantly influences cleaning outcomes and the risk of unintended consequences. A wide-angle nozzle disperses water over a larger area, reducing the force directed at any given point, while a narrow nozzle concentrates the stream, enhancing risk levels.

Water Pressure and Flow Rate

Be attentive to the specifications of both water pressure and flow rate. High pressure can lead to structural concerns if misdirected at sensitive areas. Always assess the PSI (pounds per square inch) and GPM (gallons per minute) of your device. For most residential uses, a lighter setting is advisable to prevent issues.

Material Compatibility

Materials of your pipes play a pivotal role in determining safety during usage. For instance, PVC and older iron pipes may not withstand intense streams well. Consult manufacturer guidelines to establish compatibility, and consider a lower pressure for more delicate materials. Regular inspections will also help identify potential vulnerabilities before initiating cleaning sessions.

Identifying Vulnerable Plumbing Materials

Certain materials in your system are susceptible to high-pressure cleaning methods. Recognising these can prevent issues before they arise. Copper and PVC are among the most common materials that may be negatively impacted. Copper pipes can become dented or even punctured if subjected to excessive force. Similarly, joints and connections in PVC can experience deformations, leading to leaks.

Casting and Galvanised Steel

Cast iron pipes, while robust, can develop cracks with intense water pressure, particularly if they are aged or already compromised. Galvanised steel tends to corrode over time, and high-pressure application accelerates this degradation, increasing the risk of ruptures.

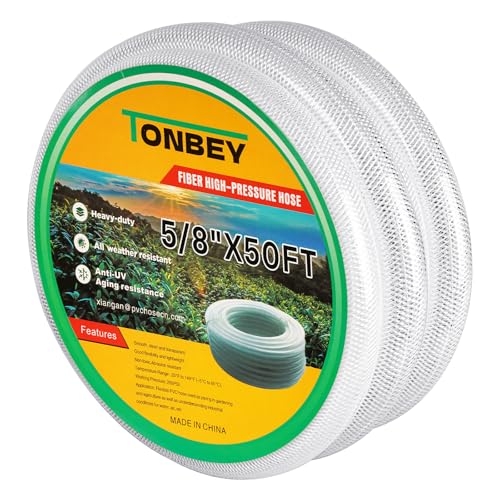

Composite and Flexible Hoses

Composite materials, often used in flexible hoses, are particularly fragile. Applying strong jets can cause tears or separations at the fittings, resulting in leaks. Always inspect hoses for wear and consider alternatives designed to withstand harsher conditions if you frequently use high-force washing methods.

Impact of High Pressure on Pipe Connections

Always assess the suitability of your connections before applying high-velocity streams. Areas where pipes join are particularly susceptible to stress fractures and leaks. High force can compromise the integrity of threaded connections, causing them to loosen over time or even break apart.

Weak Points in Connection Types

Plastic fittings, often used in household plumbing, lack the durability of metal ones. If exposed to extreme turbulence, these components can crack or burst. Metal connections might seem robust, but they can also succumb to severe stress, particularly if they are already exhibiting signs of corrosion or wear. Regular examinations of joints will help in identifying potential problem areas before they become critical failures.

Pressure Calibration and Connection Security

Utilising adjustable settings on your equipment is essential. When dealing with vintage or fragile infrastructures, a lower setting may suffice for effective cleaning without risking integrity. Additionally, verify that all connections are tightly secured; loose joints are prime candidates for failure under extreme conditions. Investing in quality connectors can also provide added assurance against high-impact forces.

Assessing the Risks of Clogged Drains

Always prioritise regular maintenance of your drainage system to prevent blockages. If you’re considering using high-pressure cleaning equipment, understanding potential risks is crucial.

Identifying Potential Causes of Clogs

- Accumulation of grease, soap scum, and hair can significantly reduce flow.

- Invasive tree roots that enter through cracks in the pipes may obstruct water passage.

- Mineral buildup in older pipes can limit diameter, leading to backups.

Preventative Measures

- Conduct routine inspections with a professional to identify problem areas.

- Utilise enzymatic cleaners that break down organic material without harming pipes.

- Install strainers over drains to catch debris before it enters the system.

Before using high-pressure equipment, consult experts to confirm your pipes can handle the intense force. Each drainage system has unique tolerances; using equipment that exceeds these limits can result in unforeseen consequences. Regular maintenance and informed decision-making are key to avoiding clogs and ensuring a smooth flow in your plumbing system.

Preventative Measures to Protect Plumbing

Always inspect your piping system before proceeding with any cleaning. Check for any potential weak points, such as cracks, corrosion, or loose joints. Address these issues beforehand to mitigate the risk of compromises during high-pressure tasks.

Utilise a lower setting on the equipment to minimise impact on your system. Many units come with adjustable pressure levels; use these features wisely to tailor the intensity to your specific needs.

Use a nozzle designed for wider spray patterns. This reduces the concentrated force on a single area and disperses the pressure, which lessens the likelihood of harm.

Regular Maintenance Checks

Implement scheduled inspections and maintenance of your pipes. This will not only prolong their lifespan but also help in identifying vulnerabilities that could lead to problems during high-pressure applications.

Consider Alternate Cleaning Methods

In certain cases, relying on non-pressurised methods, such as manual scrubbing or chemical cleaners, may be safer options. This can prevent unnecessary wear and stress on your piping system.

Choosing Safe Pressure Washer Settings

For optimal safety while using a high-powered cleaning device, select the lowest suitable setting first. Start with a pressure level of around 1,500 PSI and gradually adjust according to the surface and cleaning requirements. This minimises risks while maximizing efficiency.

Recommended Pressure Settings by Material

| Material | Recommended PSI |

|---|---|

| Wood (decking) | 1,200 – 1,500 |

| Brick/Concrete | 2,000 – 3,000 |

| Vinyl Siding | 1,500 – 2,000 |

| Metal | 2,000 – 3,200 |

| Glass | 1,500 |

Adjust the nozzle tip accordingly; using a narrower spray angle increases pressure but also risk. Consider a fan spray for broader areas and a narrower spray for targeted cleaning. Additionally, maintain distance–keeping the nozzle at least 12 inches away from the surface protects materials from excessive force.

Regularly inspect the cleaning mechanism for any signs of wear or damage. A malfunctioning unit can cause inconsistent pressure, potentially leading to mishaps. Lastly, always consult the manufacturer’s guidelines to ensure adherence to safety standards specific to your equipment.

FAQ:

Can using a pressure washer cause damage to my plumbing system?

Yes, using a pressure washer can potentially damage your plumbing system. High pressure can lead to leaks or burst pipes, especially if the plumbing is old or not well-maintained. It’s essential to use the correct pressure settings and techniques.

What are the signs that my plumbing has been damaged by a pressure washer?

If you’ve used a pressure washer and notice leaks, strange noises, or fluctuating water pressure afterward, these could be signs of damage. Any visible cracks or deterioration in your pipes should also raise concerns.

Is it safe to use a pressure washer on outdoor plumbing fixtures?

Generally, it’s safe to use a pressure washer on outdoor plumbing fixtures, but caution is advised. Make sure to keep the nozzle at a safe distance and avoid using excessive pressure, as this might damage the fixtures or the surrounding plumbing lines.

What precautions should I take before using a pressure washer near my plumbing?

Before using a pressure washer, inspect your plumbing for any existing issues. Ensure that all joints and connections are secure. It’s advisable to use the lowest effective pressure and maintain a safe distance from pipes and joints to reduce the risk of damage.

Can professional pressure washing prevent plumbing issues in the long run?

Professional pressure washing can help maintain the exterior of your plumbing system by removing buildup that could lead to blockages. While it might not directly prevent plumbing issues, keeping your fixtures clean can contribute to their longevity and reduce the risk of future problems.