Using a high-pressure cleaning device with your tap is entirely feasible and often a practical approach. To achieve this, I recommend using a suitable hose and an adaptor that can securely fit onto your tap’s threading. Ensure the specifications match your cleaning equipment for optimal water flow and performance.

Before you proceed, inspect the water outlet for compatibility. Most standard taps can accommodate a connection, but some may require specific fittings. A quick trip to a local hardware store should provide you with the necessary adaptors, often readily available in various sizes.

Keep in mind the water pressure from your tap; it should align with the requirements of your cleaning unit to maintain efficiency. I suggest testing the water flow before starting your cleaning tasks. This step will help you avoid potential damage to both the cleaning device and the plumbing system.

Direct Water Supply Compatibility

Utilising a standard tap for high-powered equipment is feasible, provided specific guidelines are adhered to. Ensure the water flow rate meets the device’s requirements, which typically ranges between 5 to 10 litres per minute, depending on the model. Insufficient flow can lead to overheating and damage. Verify the tap’s connector compatibility; using the appropriate adaptor is essential for a secure fit.

Piping and Hose Setup

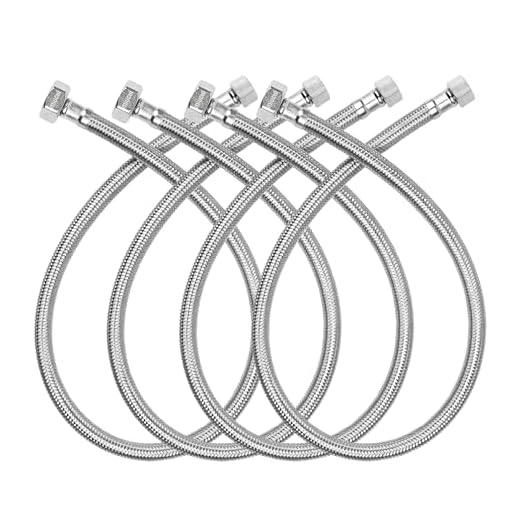

Utilise high-quality hoses that can withstand the operational pressure, generally rated higher than the machine’s specifications. Reinforced hoses are recommended for durability. Maintain a short, straight line from the tap to minimise pressure loss, taking care to avoid any kinks that could restrict water flow.

Alternatives and Precautions

In scenarios where connecting directly isn’t suitable, consider diverter valves that allow switching between your main water supply and the device. This can enhance flexibility without compromising performance. Regularly check for leaks and perform maintenance on both tap and hose to ensure longevity and reliability. Keep an eye on the water source quality, as contaminants could damage your equipment over time.

Understanding Connection Types

Begin with sourcing the correct adapter or nozzle that fits your device’s inlet. Various models utilise different thread sizes and connection styles. Identify whether the item uses a quick-connect system or standard hose threads. For compatibility, always refer to the manufacturer’s specifications before proceeding.

Adapters play a significant role in achieving the desired fit. If your hose features a standard ¾ inch connection, check if your equipment requires an alternative size. You may need a garden hose adapter for standard fittings, while some brands offer proprietary connections that require specific attachments. Avoid mixing incompatible parts, as this can lead to leaks or inadequate performance.

Another aspect is the water source. Ensure that the water supply can maintain the necessary flow rate, usually specified in litres per minute, to avoid operational issues. Establishing a secure connection to a reliable source can substantially enhance the performance of your device.

Special attention should be given to the pressure regulation settings of your appliance. Some models come equipped with adjustable pressure controls, allowing for a tailored cleaning experience. Verify that these settings align with the intended application for optimal results.

To prevent any accidental disconnections during operation, check for secure fittings and consider employing thread seal tape on threaded joints. This simple step can prevent unwanted water leakage and ensure a more consistent cleaning experience.

In summary, understanding connection types is essential for maximising the potential of your cleaning appliance. Pay meticulous attention to fittings, compatibility, water flow, and pressure settings to achieve efficient performance in your cleaning tasks.

Getting the Right Adapters for Sink Connection

For proper setup, specific adapters are necessary to facilitate the attachment of your cleaning dynamo to a standard tap. These components often vary based on the type of faucet. It’s crucial to ascertain the thread type of your tap, which may be either female or male, and the diameter, which typically falls within ranges of 0.5 to 0.75 inches.

Identifying Required Adapters

.jpg)

Purchase a garden hose connector that aligns with your tap size. If your nozzle has a quick-connect feature, ensure that the adapter also accommodates that design to streamline the installation process. For taps that do not have standard threading, a compression fitting may be necessary. Always check the packaging for compatibility claims before acquiring any adapter.

Using Additional Hoses

If your set-up requires a longer reach, consider investing in a hose extension that matches the diameter of your existing connection. This prevents leaks that can occur from connectors not being compatible in size. When utilising any hoses, ensure they are rated for the same water flow rate to maintain optimal performance.

Lastly, I recommend keeping a variety of adapters on hand for flexibility. The right fittings not only enhance your experience but also ensure a secure connection, reducing the risk of leaks or water back-pressure that could damage equipment.

Checking Water Flow Rate Requirements

I recommend verifying the water flow rate available at your tap prior to attempting any assembly. For optimal operation of cleaning equipment, a flow rate of at least 6 to 8 litres per minute is typically required. A lower flow can lead to inadequate performance and potential damage.

To measure the flow rate, attach a bucket with a known volume–such as a 10-litre container–and time how long it takes to fill. If it fills in less than 1.5 minutes, you meet the minimum requirement for most models.

Additionally, consider the pressure specifications rated by your unit. Water pressure should range between 20 and 100 psi at the source for effective functionality. Ensure your tap is providing adequate pressure by monitoring the water flow while fully opening other faucets in the same system.

If the flow rate is below the recommended levels, it may necessitate adjustments, such as using a different water source or adding a booster pump to enhance flow and pressure. Always consult your product’s manual for specific requirements tailored to your particular model.

Safety Precautions for Connecting to a Sink

Always ensure you wear appropriate protective gear, including gloves, goggles, and non-slip footwear. These items are crucial to safeguard against potential splashes and falling objects while working with high-pressure equipment.

Before starting any operation, inspect all equipment for wear or damage. Look for cracks in hoses, leaks, or faulty connections. Replace any compromised components immediately to prevent accidents.

Ensure that the water supply is stable and turned off when making or adjusting any connections. This helps to avoid unexpected pressure build-up, which can lead to injury.

Utilise a backflow preventer if the water supply is connected to a domestic plumbing system. This device shields your water supply from contamination, which is vital for maintaining health safety standards.

Keep the immediate area clear of obstacles. A tidy workspace reduces the likelihood of tripping or stumbling on tools and equipment, enhancing overall safety as you work.

Be attentive to your surroundings, especially when using electric models. Avoid using outside in wet conditions, and keep cords dry. If rain is imminent, seek alternative areas or postpone tasks until conditions improve.

Finally, avoid directing the nozzle at people or animals. High velocity can cause injury, and ensuring safe distances protects everyone in the vicinity.

Troubleshooting Common Connection Issues

Start with inspecting the fittings; ensure they are properly threaded and compatible with the hose in question. A loose connection could lead to leaks or inadequate water supply, preventing optimal performance.

Next, check for kinks or blockages in the flexible tubing. Any obstruction can severely limit water flow, which is essential for functionality. Tight bends in the hose can also create back pressure, leading to equipment damage.

Verify the availability of sufficient water pressure from the tap. Insufficient pressure may occur due to multiple outlets being in use simultaneously. Always test the water flow at maximum capacity from the faucet before attaching the hose.

Assure that all necessary adapters are securely attached and not worn or damaged. Over time, threaded connectors can wear down, leading to leaks. A quick inspection should help identify any issues that could impede the flow.

Inconsistent water temperature can also affect performance. If the water is too cold, it might not exit forcefully enough through the nozzle. Warm water can enhance effectiveness, but ensure it is within the acceptable temperature range specified by the manufacturer.

Here’s a quick reference table summarising the common issues and solutions:

| Issue | Possible Solution |

|---|---|

| Loose fittings | Tighten all connectors and ensure compatibility |

| Kinked hose | Inspect and straighten the hose |

| Low water supply | Check water flow at the faucet |

| Worn adapters | Replace any damaged parts |

| Inconsistent temperature | Use water within the recommended temperature range |

With these checks and fixes in mind, you can efficiently address common connection problems and ensure optimal use of your cleaning equipment.

Alternatives to Using a Sink for Water Supply

One suitable alternative for sourcing water is a garden hose connected to an outdoor tap. This method often provides higher water flow rates and eliminates the risk of damaging plumbing fixtures typically associated with indoor connections.

Another option is to fill a large water tank or drum with clean water. Utilising a tank can maintain water pressure and allow for extended cleaning sessions without frequent refills. Ensure the tank has a standard outlet compatible with your equipment.

Rainwater harvesters can also serve as an excellent water source. Collecting rainwater in a barrel not only conserves resources but ensures a sustainable supply for cleaning tasks. Just make sure to filter the water to avoid debris issues during use.

If mobility is a priority, consider using a portable water tote. These containers are designed for transporting water, allowing flexibility in location without being tethered to a fixed supply.

Lastly, nearby water bodies such as ponds or lakes can be utilised with proper suction attachments. However, confirm local regulations and ensure water quality is suitable for your needs to avoid causing damage to your equipment.

Maintenance Tips for Cleaners After Use with Taps

After using cleaners with a tap supply, immediate maintenance is vital for longevity and performance.

- Flush with Clean Water: Run fresh water through the unit for several minutes to clear out any residual cleaning agents or debris.

- Check Filters: Remove and clean any inlet filters to prevent clogs. Rinse them thoroughly and ensure they are free from any build-up.

- Inspect Hoses: Examine hoses for any kinks or damage. Ensure connections are secure and there are no leaks.

- Drain the System: Empty the unit and any connected hoses to prevent water from freezing in colder climates, which can damage components.

- Store Properly: Keep the equipment in a dry place. Avoid exposing it to extreme temperatures or direct sunlight.

Regular inspections enhance functionality and safety.

- Examine Connections: Ensure all connections are tight and leak-free. Address any issues promptly to maintain performance.

- Lubricate O-Rings: Apply silicone lubricant to O-rings on connections to prolong their lifespan and ensure a tight seal.

- Check Pressure Levels: Test pressure settings occasionally to verify they align with manufacturer recommendations.

Maintaining equipment after each use ensures reliability and optimal performance during future tasks.

FAQ:

Can I connect a pressure washer directly to my kitchen sink?

Yes, you can connect a pressure washer to a kitchen sink, but there are several factors to consider. First, ensure that the sink has a suitable faucet that can accommodate the pressure washer’s hose attachment. You might need an adapter to fit the pressure washer’s connection to your sink’s faucet. Additionally, check the water flow rate from your sink, as some pressure washers require a minimum flow rate to operate effectively. Lastly, ensure that your sink plumbing can handle the pressure washer’s water output without causing any leaks or damage.

What do I need to be aware of when connecting a pressure washer to a sink?

When connecting a pressure washer to a sink, it’s important to consider the compatibility of your faucet and the pressure washer’s hose. Not all faucets are designed to fit pressure washer connections, so you might need an appropriate adapter. Also, ensure that the sink can provide a sufficient water flow to keep the pressure washer operating without interruption. It’s advisable to check if there are any restrictions or guidelines from the pressure washer’s manufacturer regarding water sources and connections to avoid warranty issues.

Will connecting a pressure washer to a sink reduce its performance?

Connecting a pressure washer to a sink can affect its performance depending on several factors. If the sink does not provide an adequate flow rate, the pressure washer may not get enough water, leading to a decrease in pressure and performance. Additionally, if there are any restrictions in the hose or the faucet, it might hinder water flow. To ensure optimal performance, it’s best to verify the specifications of your pressure washer and the water supply to make sure they are compatible.

Can I use hot water from the sink for my pressure washer?

Using hot water from your kitchen sink with a pressure washer depends on the model of the washer. Some pressure washers are designed to handle hot water while others are only suitable for cold water. Check the manufacturer’s guidelines for your specific model to determine if hot water is permissible. If your pressure washer can utilise hot water, make sure to monitor the temperature to avoid any potential damage to the machine.