The combination of a flexible water conduit and a high-pressure cleaner is not advisable. The operational requirements of a high-powered cleaning device exceed the capabilities of most lightweight water lines. In general, these equipment pieces are designed to handle water flow at a significantly higher pressure than what a standard or compact line can tolerate.

Specifications reveal that a typical high-pressure apparatus demands a flow rate often upwards of 5 gallons per minute while pushing water at pressures that regularly exceed 1500 PSI. Using a flexible water conduit, which may only sustain around 40-60 PSI, can lead to bursting, kinking, or other forms of failure, resulting in damage to both the line and the cleaning unit.

For optimal performance and safety, I recommend investing in a robust connection specifically designed to withstand high-pressure environments. Only high-quality, heavy-duty alternatives should be considered for integrating into such high-demand applications, ensuring longevity and reliability during cleaning tasks.

Compatibility of Compact Water Delivery Systems and High-Pressure Equipment

It’s advisable not to connect a compact water delivery system to high-pressure cleaning equipment. These systems are designed for low-pressure applications, typically around 60 psi, while high-pressure machines can exert forces exceeding 2000 psi. This discrepancy can lead to significant damage and potential hazards.

Risks of Connection

High-pressure machinery can easily rupture the material of a compact delivery system, causing leaks or bursts. Furthermore, the fittings may not be compatible, leading to unstable connections that could result in dangerous sprays or pressure loss. Over time, the intense water flow can deteriorate the material of the compact delivery system, negating its effectiveness.

Recommendations for Alternatives

For optimal performance and safety, select a water delivery solution specifically engineered for use with high-pressure cleaning tools. Look for systems rated to handle high pressure and designed to accommodate the required flow rates of your cleaning device. Investing in the correct setup will enhance efficiency and prolong the life of your equipment.

Compatibility of Pocket Hoses with Pressure Washers

I recommend exercising caution when connecting flexible tubing to high-pressure cleaning systems. While these accessories are designed for lightweight gardening tasks, their performance under the demands of cleaning machinery may prove inadequate.

Key Considerations

- Pressure Threshold: Most lightweight tubing is not rated to withstand the high pressures generated by these machines. Such exposure could lead to ruptures or failure.

- Connection Fittings: Ensure that the connectors on both ends are compatible. Incompatible fittings may cause leaks or disconnections during operation.

- Length and Flexibility: Longer lengths might lead to less efficient water flow. Increased flexibility can also result in kinks that hinder performance.

- Material Durability: Examine the material composition; thinner materials may degrade quickly under high-pressure and high-temperature conditions.

Alternative Recommendations

- Consider investing in hoses specifically designed for high-pressure applications. They are built to endure stringent conditions and maximize efficiency.

- Look for robust attachments that fit standard nozzles for seamless compatibility.

- Regularly inspect any garden piping prior to use if attempting to connect, ensuring there are no signs of wear or damage.

Ultimately, while the intention to adapt lightweight tubing for cleaning tasks is understandable, it’s paramount to prioritize safety and efficiency by selecting appropriate equipment designed for the job.

Identifying the Right Nozzle for Pocket Hoses

Selecting the appropriate nozzle enhances cleaning results significantly. Opt for one that matches the task’s requirements. For general cleaning, a fan or wide spray nozzle is advisable; these provide an adequate spread of water while avoiding excessive pressure that might damage surfaces.

Nozzle Types

Consider a variable nozzle if versatility is needed. This type allows for easy adjustments between different spray patterns, adapting to surfaces varying from delicate car exteriors to sturdy concrete.

Attach the Nozzle Securely

Ensure the nozzle fits tightly to prevent water leakage and maintain optimal pressure. Regularly check for wear and tear, replacing any damaged components promptly to guarantee consistent performance.

Potential Risks of Using Pocket Hoses with High Pressure

High-pressure cleaning tools can exceed the capabilities of standard flexible tubing. Running such equipment through these lightweight lines poses risks of ruptures or tears, which can lead to serious water damage or personal injury. Ensure to examine the manufacturer’s guidelines for applicable pressure ratings before mixing these items.

Another concern involves reduced water flow. High-pressure systems require adequate water volume to operate effectively. Using lightweight models may restrict flow and lead to lower cleaning efficiency, resulting in additional time spent on tasks.

Furthermore, the connectors may not be compatible, risking leaks at the junction points. Regular checks on fittings and connections are necessary to avoid unexpected failures.

Finally, consider the long-term durability of these materials. High wear and tear from increased pressure could result in premature degradation, necessitating replacements more frequently than anticipated. It’s prudent to weigh these considerations carefully before attempting to blend these products.

Best Practices for Connecting a Pocket Hose to a Pressure Washer

For optimal performance, adhere to the following practices when linking a flexible tubing solution to a cleaning unit. Ensure that your connectors are compatible; often, standard fittings work best. Specifically, verify that the thread size aligns with the unit’s inlet to prevent leaks.

Correct Pressure Settings

Adjust the output settings on the machine to a lower pressure. Start at around 1500 PSI, which generally suits lightweight garden tubes. Observing the flexibility limits will help prevent burst scenarios or material degradation.

Routine Inspections

Regularly check for wear and tear on the connectors and the flexible tube itself. Severe twisting or kinking can damage internal structures, leading to potential failures. Replace components as necessary to maintain integrity.

Alternatives to Pocket Hoses for Pressure Washing

For high-pressure tasks, opt for a traditional rubber or reinforced hose. These products can withstand greater force and provide durability in demanding conditions. Unlike flexible alternatives, robust hoses ensure a consistent water flow, crucial for effective cleaning.

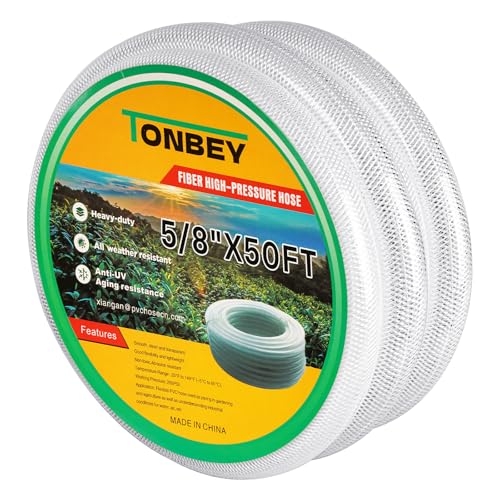

Reinforced PVC Hoses

Reinforced PVC models offer an excellent balance between weight and strength. They feature internal braiding, which prevents kinking and enhances pressure resistance. Choose a thickness appropriate for your equipment to maximise compatibility and efficiency.

Heavy-Duty Rubber Hoses

Rubber types excel under high temperatures and resist wear over time. These hoses maintain flexibility even in cold weather, preventing cracking. Additionally, they provide superior connectors, ensuring leak-free operation during extended use.

Be sure to consider hose length. A longer length might limit pressure, so select a size that meets your cleaning reach without unnecessary extensions. By opting for standard options, you ensure reliability and performance in your tasks.

Customer Reviews on Using Pocket Hoses with Pressure Washers

Feedback from users on pairing flexible tubing with high-pressure equipment is mixed. Personal experiences often highlight specific issues that can arise, which seem beneficial to consider.

Common Feedback Themes

- Performance Issues: Many consumers report that maintaining adequate pressure is challenging. The lightweight design of flexible tubing may not withstand the force generated by various cleaning machines.

- Connection Challenges: Some users encounter difficulties finding adapters that fit both the tubes and the high-pressure apparatus. Inconsistent fittings can lead to leaks, which affect overall efficiency.

- Durability Concerns: A fair number of reviewers express dissatisfaction with the lifespan of such tubing under high-stress conditions. Frequent replacements due to wear and tear were noted.

Positive Outcomes

- Lightweight and Portable: Several users appreciate the ease of handling and storage, especially for lighter cleaning tasks where strength isn’t a primary concern.

- Convenient for Small Jobs: Some individuals find that this flexible solution works adequately for smaller cleaning tasks, such as rinsing vehicles or watering plants.

Ultimately, personal experiences vary widely. It’s essential to evaluate intended applications and weigh the potential drawbacks against the benefits reported by other users.

Maintenance Tips for Flexible Water Tubes After High-Pressure Cleaning

Rinsing the garden reel thoroughly after each use is critical to prevent debris accumulation. A gentle stream of water is effective in removing dirt without causing damage.

Drying

Always allow the irrigation line to dry completely before storing. This helps prevent mould and mildew growth, which can compromise the material over time.

Storage Guidelines

Store in a cool, shaded area, away from direct sunlight. UV exposure can weaken the fabric, leading to leaks and other issues.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Rinse after use | Every use | Prevents dirt build-up. |

| Inspect for leaks | Weekly | Check connections and material integrity. |

| Dry completely | After each use | Avoids mould and mildew. |

| Store properly | Off-season | Cool and shaded location recommended. |

Inspect all connectors and fittings regularly. Damaged parts should be replaced promptly to avoid pressure loss and potential hazards during operations.

Avoid dragging the flexible line over rough surfaces. This will extend its lifespan and maintain performance under high pressure.