Yes, it is possible to address issues with high-pressure cleaning equipment tubing. My experience in the cleaning equipment industry has shown that many common problems can be resolved without the need for complete replacement. Identifying the source of the issue is crucial–whether it’s a small leak, a damaged connector, or a kink affecting performance.

For minor leaks, I recommend using a high-quality repair tape specifically designed for high-pressure environments. Wrap the tape tightly around the damaged area, ensuring a snug fit. This method can restore functionality for a period, but be aware that it’s a temporary fix. For more severe damage, consider replacing just the compromised section rather than the entire tubing. Cutting out the damaged area and using compatible couplings can achieve a seamless repair.

Regular maintenance can extend the life of your cleaning equipment. Inspect tubing frequently for wear and tear, and store it properly to prevent kinks and abrasions. Understanding the materials and construction of your specific model will guide you in selecting the best repair method. With the right approach and tools, I have successfully fixed various issues that might otherwise lead to costly replacements.

Repairing Cleaning Equipment Hoses

Yes, it’s possible to fix these types of hoses, but the success largely depends on the damage extent. For minor leaks or cuts, using a hose repair kit can be effective. These kits typically include connectors and clamps designed for quick and reliable fixes. Ensure the hose is completely dry before applying any repair solution for optimal adhesion.

Steps for Effective Repairs

First, assess the damage. If the cut is smaller than an inch, a repair connector is often sufficient. Cut the hose at the damaged section, then attach a connector using the hose clamps provided in your repair kit. Make certain the clamp is tightened securely to prevent any future leaks.

In Cases of Severe Damage

If an area is extensively worn or punctured, replacing that segment might be necessary. Cut out the damaged section and use a coupling to connect two intact parts of the hose. Ensure the replacement lengths match in diameter to maintain stable flow and pressure. If multiple areas are affected, it may be prudent to consider a replacement instead.

Regular maintenance can prolong the life of your equipment. Inspect the hose frequently for signs of wear and perform preventive upkeep to minimise the need for repairs.

Identifying Common Hose Damage Types

Inspecting your cleaning device’s tubing regularly is crucial to ensuring longevity and peak performance. Here are the prevalent types of damage I often come across:

- Leaking Fittings: Pay attention to the connections on both ends. Any signs of moisture or water leaking indicate that the fittings may need tightening or replacement.

- Cracks and Cuts: Examine the exterior for visible cracks or cuts, which can occur from exposure to harsh surfaces. Even minor damage can lead to significant leaks over time.

- Kinks and Abrasions: A kinked tubing disrupts water flow, while abrasions weaken the material. Regularly check for bends and try to minimise them during storage.

- Bulges: A bulge in the tubing signals internal pressure issues. This condition can lead to bursting if not addressed promptly.

- Corrosion: Inspect for signs of rust or corrosion, especially if the apparatus is often exposed to moisture. Choose materials that resist deterioration for longer-lasting use.

By identifying these issues early, you can take action to maintain the integrity of your cleaning apparatus and enjoy optimal performance. Always keep a close eye on the condition of your tubing for effective operation.

Step-by-Step Guide to Patch Minor Leaks

First, gather necessary materials: rubber patch or tape, utility knife, sandpaper, and adhesive. Ensure you have a clean working space.

1. Identify the Leak: Thoroughly inspect the exterior for moisture or damage. If needed, use water to reveal hidden leaks.

2. Prepare the Area: Remove dirt and debris around the leak using a cloth. Gently sand the damaged section to create a smooth surface for better adhesion.

3. Cut the Patch: From the rubber material, cut a piece slightly larger than the damaged area. Ensure it fits snugly to cover the leak completely.

4. Apply Adhesive: Evenly spread a strong adhesive on both the patch and the damaged area. Allow the adhesive to become tacky before proceeding.

5. Attach the Patch: Carefully place the patch over the leak, pressing down firmly to eliminate air bubbles and ensure a tight seal.

6. Secure the Edges: Use tape around the edges of the patch to provide additional reinforcement and prevent lifting over time.

7. Curing Time: Allow the repair to cure as per the adhesive manufacturer’s instructions. Avoid using the equipment until fully cured to ensure a lasting fix.

8. Final Inspection: Once cured, do a final check to ensure the patch is secure. Test the equipment gently to ensure no leaks persist.

This approach not only saves time but extends the life of your equipment, allowing for efficient cleaning without unnecessary interruptions.

When to Replace vs. Repair a Pressure Washer Hose

Switch to replacement if your unit shows significant wear or severe damage, such as extensive abrasions, deep cuts, or persistent leaks that cannot be sealed effectively. In cases where the diameter of the line is compromised or there are multiple damaged areas, investing in a new item is more practical.

Evaluate the age and overall condition of your current equipment. If it has served you well for several years and issues are starting to accumulate, consider replacing it. Conversely, if the product is relatively new and only minor problems are present, repair might be the most economical choice.

| Criteria | Replace | Repair |

|---|---|---|

| Extent of Damage | Severe cuts, multiple leaks | Minor leaks, small abrasions |

| Age of Equipment | Several years old | Less than two years |

| Cost of Repair | Higher than new item | Cost-effective solution |

| Performance Issues | Reduced flow, excessive pressure loss | No significant impact on functionality |

When weighing your options, assess the repair process against the cost and lifespan of a new unit. Choose replacement when a quick fix would only lead to further problems down the line. Trust your experience with tools and equipment. It’s often more beneficial to invest in reliable, durable gear that will serve you well in the long run.

Tools and Materials Needed for Hose Repair

To effectively carry out repairs on your high-pressure cleaning equipment’s tubing, gather the following items:

1. Replacement Parts: Depending on the damage, you may need connectors, end fittings, or reinforcing sleeves. Ensure they are compatible with the existing setup.

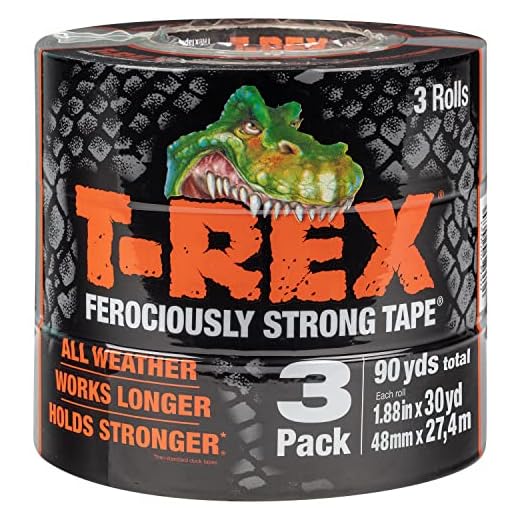

2. Hose Repair Tape: This waterproof tape is crucial for sealing small leaks. Look for a durable, rubberised version to provide a reliable bond.

3. Scissors or Utility Knife: A sharp cutting tool is essential for trimming away damaged sections and preparing the hose ends for repairs.

4. Wrench Set: Use this for loosening and tightening fittings. An adjustable wrench can be particularly useful if you don’t have the exact size needed.

5. Heat Gun or Hair Dryer: These tools are helpful for heating shrink tubing, ensuring a tight fit over damaged areas or exposed ends.

6. Safety Gear: Always wear gloves and safety glasses. This will protect against accidental cuts and flying debris during repairs.

7. Measuring Tape: Accurate measurements are necessary for ensuring that replacement sections fit properly with existing components.

8. Waterproof Adhesive or Silicone Sealant: Use these materials to seal small leaks effectively. Choose an adhesive that can withstand high pressure and temperature variations.

9. Ruler or Straight Edge: For marking precise cutting lines, ensuring clean and straight cuts that promote better sealing.

With these tools and materials at hand, you can confidently approach the task, ensuring a well-executed repair that maintains optimal function. Always double-check compatibility and specifications before starting any project.

Safety Precautions During the Repair Process

Wear appropriate personal protective equipment (PPE), including safety goggles, gloves, and sturdy footwear. These items shield against potential injuries from water or debris.

Work Area Prep

Ensure the workspace is dry and clutter-free. Remove any obstacles that could lead to slips or falls. A clean environment not only aids focus but also minimises hazards.

Proper Equipment Handling

Disconnect the cleaning device from its power source before beginning repairs. This prevents accidental activation during maintenance. Check that tools are in good condition; damaged tools can create dangerous situations.

Examine the hose for residual pressure before any repair activity. Release any trapped air or water by detaching one end away from a surface. Aim the disconnected end in a safe direction to avoid injury.

When using adhesives or sealants, work in a well-ventilated area to prevent inhalation of harmful fumes. Always follow the manufacturer’s guidelines for product application and curing times.

Keep a first aid kit accessible and know its contents. In case of an injury, immediate access to supplies can make a difference. It’s wise to have emergency contact numbers readily available.

Finally, avoid working on damaged sections if unsure about safety or repair methods. Consulting a professional may be more prudent for significant damage.

Maintaining Your Pressure Washer Hose After Repair

After fixing any leaks or damages, keeping the cleaned attachment in top shape is paramount for optimal performance. Follow these practical steps for ongoing care:

- Regular Inspection: Routinely check the hose for signs of wear, abrasions, or kinks. This swift identification of emerging issues can prevent larger complications.

- Proper Storage: Store the length in a cool, dry area. Avoid direct sunlight and extreme temperatures, which can degrade materials over time. Consider using a reel or hook to keep it tangle-free.

- Avoid Excessive Force: When moving or utilising the connection, handle it gently. Yanking or pulling can stress the material, leading to renewed damage.

- Use Appropriate Connectors: Ensure that all couplings and connectors match the specifications of your attachment. Mismatched parts can lead to leaks or additional strain on the material.

- Flush After Use: After every session, it’s beneficial to run water through the line to eliminate any residues or debris. This will extend the lifespan of the internal lining.

- Periodic Cleaning: Use a gentle soap solution to clean the exterior. Avoid harsh chemicals, as they can weaken the material and lead to failures.

- Check Fittings: Regularly inspect the fittings for tightness. Loose connections can lead to leaks and should be tightened or replaced if damaged.

Following these guidelines will extend the functionality and durability of your repaired item, ensuring it serves you well for many projects to come. Consistent care pays off in performance and longevity.