If faced with a damaged segment of your cleaning equipment’s tubing, a timely response is critical. Begin by turning off the machine and disconnecting it from the power source to ensure safety. Once this is done, inspect the area around the affected site carefully. A simple yet sturdy patch made from a rubber or silicone material can often serve as an effective temporary solution.

First, clean the damaged area thoroughly to remove dirt and moisture, as a clean surface is paramount for secure adhesion. Measure the size of the rupture and cut a piece of rubber that is approximately 2-3 inches larger than the damaged zone. Apply a strong adhesive suitable for high-pressure environments liberally beneath the patch, then press it down firmly. Allow adequate time for the adhesive to cure fully, adhering snugly to both the tubing and the patch.

For a more durable fix, consider using hose repair kits available on the market. These kits typically include connectors and clamps designed to withstand high pressure. Cut away the damaged portion of the tubing, insert the connector, and secure everything with clamps for a reliable restoration. This option can provide peace of mind and extend the life of your cleaning apparatus significantly.

Repair a Damaged Cleaning Equipment Hose

Patch the disrupted segment effectively by utilising an appropriate repair kit designed for high-pressure tubing. Begin by thoroughly cleaning the affected location to ensure optimal adhesion of the repair material.

Here’s a step-by-step approach:

- Identify the exact location of the impairment. While the damage might be visible, inspect the entire length of the line for any additional discrepancies.

- Prepare your workspace. Ensure that the system is disconnected from the power source and any water supply.

- Utilise a utility knife or scissors to smoothly trim the damaged area. Ensure the cut is clean and straight.

- Position the provided repair sleeve over the trimmed segment. Follow the manufacturer’s instructions for application, typically involving wrapping the sleeve tightly around the affected area.

- Secure the sleeve with waterproof tape or clamps, ensuring it remains watertight during operational use.

- After ensuring that the repair is secure, reconnect the system and conduct a test run to check for any leaks.

Consider alternative methods such as using specialised hose repair adhesive for minor tears. Regardless of the technique employed, always prioritise safety and functionality when performing repairs.

| Repair Method | Materials Needed | Estimated Time |

|---|---|---|

| Repair Kit | Repair sleeve, tape | 30 minutes |

| Adhesive Method | High-pressure adhesive | 15 minutes |

Post-repair, inspect the area regularly to ensure no further issues arise, maintaining the efficiency and lifeline of your cleaning equipment.

Identifying the Type of Damage in the Hose

To assess the damage in the cleaning tool’s flexible tube, first inspect the area thoroughly. Look for any signs of leaks, bulges, or abrasions. Identifying the nature of the issue is key to addressing it effectively.

Small punctures are often pinpoint-sized, typically caused by sharp objects or friction. These can be challenging to notice but will usually result in a fine stream of water. A method to confirm a minor perforation involves wrapping the affected section with your hand and applying pressure while operating the equipment; if water seeps through, a small breach exists.

In contrast, larger tears create more significant issues and are typically visible as elongated slits or splits. These require immediate attention as they can compromise the entire functionality of the setup. A gentle squeeze along the length of the tube can help reveal hidden fractures by allowing water to escape.

Observe any bulging sections; this indicates weakening materials often due to wear and age. If the outer layer appears thin or frayed, consider replacing this section entirely. Look for safety compliance marks or manufacturer specifications to maintain compatibility if performing any repair.

Finally, consider the environment where the device is used. Excessive exposure to sunlight or extreme temperatures can accelerate material degradation. Regular inspections can help identify vulnerabilities before they lead to more severe problems. Remember, addressing the type of damage early can extend the lifespan of the apparatus and maintain its efficiency.

Gathering Required Tools and Materials

Prepare the following items for an efficient repair operation:

- Quality patch kit specifically designed for high-pressure tubing.

- Scissors or a sharp knife suitable for cutting rubber.

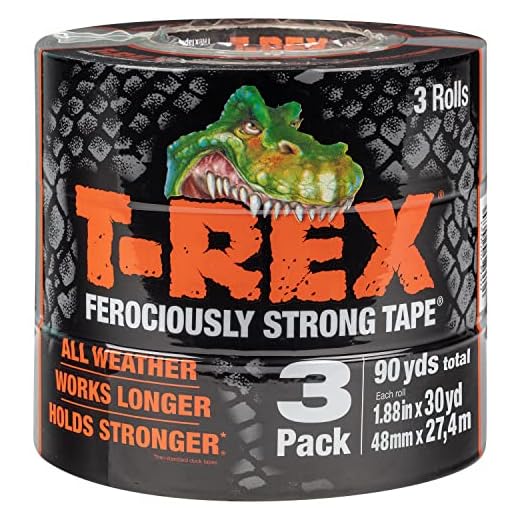

- Utility tape or electrical tape for additional sealing if needed.

- Sandpaper to roughen the surface, ensuring better adhesion.

- Clean cloth for wiping the repair area.

- Protective gloves to keep hands safe from adhesives and chemicals.

- A bucket or container to collect any residual water from the line.

Ensure the patch kit is compatible with the diameter and type of tubing being repaired. Conduct a quality check of tools before proceeding with the task for optimal results.

Cleaning the Area Around the Hole

Before starting any repair, ensure the surrounding area is clean. Remove dirt, debris, and contaminants from the vicinity of the damaged section to promote a strong bond during the sealing process. Use a mild detergent mixed with water to wash the area; this will help eliminate oils and residues that could hinder adhesion.

After cleaning, thoroughly rinse the site with fresh water to remove all detergent traces. Allow it to dry completely. This step is crucial, as moisture can interfere with the effectiveness of the repair material. If the damage is near a connector or any fittings, inspect these areas carefully to avoid further issues during the repair.

Your workspace should also be uncluttered. Having enough space to manoeuvre efficiently will make the task simpler and reduce the risk of accidents. Set down tools and materials within easy reach, ensuring a smooth workflow as you carry out the repairs.

Choosing the Right Repair Method for Your Hose

For repairing a leaky section, consider using a hose repair kit, which typically includes connector fittings. Ensure the chosen fitting matches the diameter of your tubing to maintain proper water flow. Follow the kit’s instructions for a secure seal.

Another option is employing adhesive tape designed for high-pressure applications. Wrap the tape tightly around the damaged segment, overlapping as you progress. This creates a reliable barrier against water loss, especially for smaller tears.

If the damage is significant or located near the connection points, replacing the compromised section may be necessary. Cut out the damaged area and use a coupler to join the remaining pieces, ensuring the connections are watertight.

For a more temporary solution, consider using a rubber patch secured with hose clamps. This allows for quick fixes without a permanent commitment, making it ideal for immediate, short-term fixes until a more permanent repair can be arranged.

Evaluate the severity of the damage and select the most suitable method based on functionality and longevity. Each approach has its benefits; be sure to assess your specific situation to achieve the best outcome.

Step-by-Step Guide to Use Hose Repair Tape

First, take a good quality repair tape designed for hoses. Start wrapping it around the damaged area, ensuring to cover about three inches on either side of the tear. The tape should be applied tightly for optimal adhesion.

Before applying, ensure the surface is dry; moisture affects the tape’s bond. If necessary, wipe the area with a clean cloth and let it dry completely. This will help achieve a secure fix.

Begin wrapping the tape at one end of the damaged section, making sure to overlap each layer by at least half the width of the tape. Maintain tension to ensure it adheres properly. Continue until you have several layers over the affected area.

After applying the last layer, press down firmly to seal all edges. For additional security, you can wrap electrical tape around the ends of the repair tape, providing extra durability against water pressure.

Allow the repair to set for a few hours before using the equipment. This ensures that the tape adheres well and can withstand the pressure during operation. Always check the repair after first use to confirm that it holds up.

How to Use a Hose Repair Connector

To seamlessly connect a damaged line, choose a robust hose repair connector suited for your specific diameter. Ensure the connector is compatible with the material of the line, be it rubber or PVC.

Step-by-Step Instructions

1. Preparation: Cut the affected section of the tubing cleanly to eliminate frayed edges. This step ensures a smooth fit for the connector.

2. Insert the Connector: Push the connector into both ends of the severed line. If resistance occurs, use a lubricant to facilitate the insertion without causing damage.

3. Secure the Connection: Employ screw clamps or hose clips on both ends of the connector. Tighten these firmly to prevent leaks during operation. Use a screwdriver or a socket wrench for optimal tightness.

Final Checks

Test the repair by turning on the water supply before proceeding with any tasks. Inspect for leaks and ensure everything is functioning properly. Regular inspections after use can extend the lifespan of your equipment.

Testing the Hose After Repairing

After completing the repair on your water delivery line, it’s crucial to conduct a thorough assessment to ensure the integrity of the patch. Follow these steps to test the repaired area effectively:

- Reconnect the Hose: Attach the repaired segment back to the source and check that all connections are secure.

- Gradual Water Flow: Slowly turn on the water supply to avoid sudden pressure spikes. This will help identify any immediate leaks at the repaired site.

- Observe for Leaks: Inspect the repaired section closely as water flows through. Look for any signs of fluid escaping, which would indicate an unsuccessful fix.

- Check Pressure Output: Once comfortable with the absence of leaks, activate the system to the recommended pressure level. Monitor performance; inconsistent pressure could point to issues with the connection or seal.

- Perform a Functional Test: Use the equipment in a controlled environment to verify that the repaired line delivers consistent flow and pressure. Execute several tasks to assess durability.

Keep a notepad handy to document any changes or issues encountered during testing. If problems persist, you may need to reassess the repair method or seek a replacement.

Regular testing after repairs maintains equipment longevity and ensures optimal cleaning performance. Always remain attentive to subtle signals that might indicate future complications.

Preventative Measures to Avoid Future Damage

Regular inspections of your cleaning apparatus are crucial. Check for signs of wear and tear on the tubing each time you finish a task. Look for abrasions, kinks, or any other abnormalities that could lead to leaks.

Store the tubing in a shaded, dry area and avoid harsh conditions. Ensure that it is not exposed to extreme temperatures or direct sunlight for prolonged periods, as this can degrade the material.

Utilise protective covers or reel systems when not in use. This prevents unnecessary stress and tangling, which can lead to chafing and eventual failure of the tubing.

Consider the use of high-quality additives or conditioners specifically designed for maintaining rubber or synthetic materials. These products can help in prolonging the lifespan of the equipment.

Avoid sharp objects and rough surfaces while in use or during storage. Implementing these simple precautions not only extends service life but also enhances the overall performance of your cleaning equipment.