Specific types of pipes are required for high-performance cleaning units. Using incompatible or substandard models can lead to malfunction or damage. Always opt for hoses designed for high-pressure applications to ensure optimum functionality.

Rubber and reinforced PVC hoses prove to be the most reliable choices. These materials can withstand elevated pressures without bursting or leaking. Avoid garden or standard water hoses, as they often lack the necessary durability and pressure ratings.

Before connecting, check the fittings and diameter specifications on both the hose and the machine. A mismatch may result in leaks or inadequate performance. Investing in compatible accessories guarantees efficient operation and prolongs the life of your equipment.

Regular maintenance of the selected hose is also critical. Inspect for signs of wear, kinks, or damage periodically. Treating your equipment with care enhances its longevity and effectiveness in tackling tough cleaning tasks.

Compatibility of Hoses with Pressure Cleaning Systems

Not every garden pipe or tubing component is suitable for high-pressure cleaning tasks. Specific criteria must be considered to ensure optimal performance and prevent damage.

Pressure Rating

The maximum pressure rating of the connecting line should match or exceed the specifications of the cleaning unit. Typical ratings range from 1500 to 4000 PSI. Any lower-rated option risks bursting or degrading under pressure.

Diameter and Fittings

Standard diameters range from 1/4 inch to 1/2 inch. Always verify the size required by the model. Additionally, matching coupling types is vital; most units utilise quick-connect mechanisms, ensuring a secure attachment.

- Look for reinforced options designed to withstand both wear and high pressure.

- Avoid generic fittings; instead, opt for those directly from the equipment manufacturer.

- Certain materials, like PVC, may attain flexibility but lack the durability needed for high demands; instead, prefer rubber or high-grade flexible thermoplastics.

Using incompatible equipment might lead to inefficiencies or potential hazards. Regularly inspect to ensure integrity, especially at connection points and bends.

Understanding Pressure Washer Hose Specifications

The optimal choice for hoses involves several critical specifications that must be adhered to for effective operation. Firstly, assessing the pressure rating is paramount; ensure it exceeds the machine’s maximum psi. For instance, if the unit operates at 3000 psi, select a hose rated for at least 3500 psi to prevent bursting.

Next, consider the diameter of the tubing. Most models utilise either 1/4-inch or 3/8-inch hoses. A larger diameter facilitates higher flow rates, advantageous for extensive cleaning tasks. However, matching the diameter to the connector size of the cleaning equipment ensures a proper fit and seamless water flow.

Material matters significantly; the most common options are rubber and PVC. Rubber hoses tend to be more durable and resistant to wear, while PVC varieties are often lighter and more flexible. Choosing based on the intended usage and environmental conditions can enhance longevity and performance.

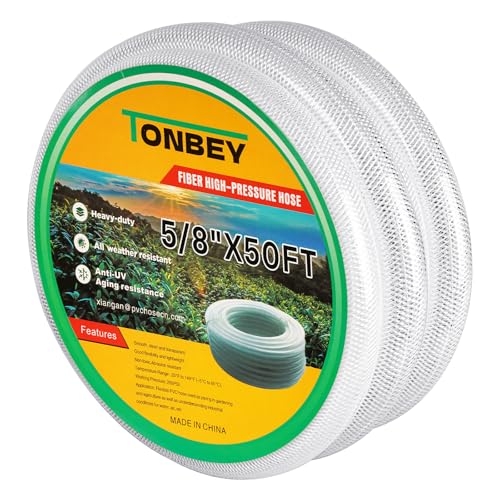

Furthermore, length plays a key role. Longer hoses offer flexibility in movement but can lead to decreased pressure due to friction loss. It’s advisable to balance reach with efficiency; a 50 to 100-foot hose typically strikes a suitable middle ground for most tasks.

In addition, look for accessories like quick-connect fittings that simplify attachment and detachment, adding convenience to the cleaning process.

Finally, always verify compatibility with your specific unit to avoid operational issues. Familiarising oneself with these specifications ultimately leads to a better cleaning experience and prolongs the equipment’s lifespan.

Compatibility of Hose Materials with Pressure Washers

Rubber and thermoplastic materials are the most suitable choices for high-pressure systems. Rubber hoses provide durability and resistance to kinking, while thermoplastic options are lightweight and flexible, making them easier to manage during usage. Either material can withstand the stress of vigorous cleaning tasks.

Considerations for Specific Hose Types

- Rubber Hoses: These can handle extreme temperatures and maintain rigidity under pressure. Ideal for rigorous tasks, rubber tends to be resistant to wear and tear.

- Thermoplastic Hoses: Lightweight and versatile, thermoplastic hoses are less cumbersome. They offer good resistance to abrasion but may have limitations in durability compared to rubber.

Avoid using vinyl or PVC hoses. These materials may not cope well with the high pressures and temperatures associated with powerful cleaning equipment. They are more prone to damage and reduced lifespan.

Maintenance Tips for Hose Longevity

- Store hoses in a shaded or climate-controlled area to prevent deterioration.

- Regularly inspect for signs of wear, such as cracks or bulges.

- Ensure all connections and fittings are appropriately tightened to avoid leaks.

Investing in a quality hose tailored for high-pressure demands significantly extends the overall lifespan of the equipment and optimises cleaning results. Prioritising compatibility with the specific cleaning system ensures not only safety but also efficiency in performance.

Factors Influencing Hose Length for Pressure Washing

The length of the connection pipe significantly impacts the operational efficiency of equipment. Shorter lengths reduce the risk of pressure loss, while extended lengths can potentially create a situation where too much energy is dissipated, leading to diminished performance. A standard guideline is to keep lengths below 30 feet for optimal efficacy.

Impact of Facility Layout

Architectural design of the washing environment plays a key role in determining required length. In compact areas, shorter segments are often ideal, whereas larger outdoor spaces may necessitate longer ones. Careful calculations will help achieve the best results without compromising pressure.

Weight and Maneuverability

Weight adds to the fatigue during use, particularly with longer alternatives. A balance must be achieved between extended reach and ease of handling. Look for lightweight materials that offer flexibility, making it simpler to navigate tight corners or uneven surfaces.

Identifying Hose Diameter Requirements for Pressure Washers

For optimal performance, it’s crucial to match the diameter of the connecting pipe to the specifications of the equipment. Standard diameters for hoses typically range from ¼ inch to ½ inch. The size impacts both water flow and pressure delivered during operation.

Choosing a diameter smaller than required may restrict flow, leading to reduced pressure and efficiency. Conversely, a larger diameter might lead to inadequate sealing and increased water loss. Always refer to the manufacturer’s guidelines for the exact requirements of your cleaning device.

| Hose Diameter | Typical Use | Pressure Range |

|---|---|---|

| ¼ inch | Light-duty models | Up to 2000 PSI |

| ⅜ inch | Medium-duty models | 2000 to 3000 PSI |

| ½ inch | Heavy-duty models | Above 3000 PSI |

Additionally, inspecting the fittings is essential. Ensure compatibility with the connector on both the equipment and the supplying source. Mismatched fittings can lead to leaks and reduced functionality.

Always remember to test the hose for kinks or obstructions that may impede water flow. Regular maintenance of both the pipe and the cleaning apparatus will extend their lifespan and prevent operational issues.

Potential Risks of Using Non-Compatible Hoses

Utilising hoses that do not match the specified requirements can lead to serious hazards. Firstly, incorrect fittings may result in leaks, causing water to spray uncontrollably and creating slippery surfaces, posing risks of slips and falls.

The pressure rating of the hose must align with the equipment’s specifications. Using a hose with a lower PSI rating can cause it to burst under high pressure, potentially injuring users and damaging surroundings. This bursting can also cause pieces of the hose to become projectiles, creating safety threats.

Materials of the hose play a significant role. For instance, rubber or PVC hoses not rated for hot water may degrade quickly, leading to steam burns or other heat-related injuries. Additionally, hoses made from incompatible materials risk breaking down from chemical exposure if cleaning agents are used, leading to hazardous situations.

Another risk comes from kinked or improperly wound hoses. Such scenarios can restrict water flow, increasing the chances of overheating in the pump mechanism. Overheating might cause permanent damage and require expensive repairs.

It’s imperative to avoid using hoses that are either too long or too short for specific tasks. An overly long hose can create excess resistance, while a short hose may place stress on connectors, leading to failure and leaks. Always ensure the right length to maintain optimal operation.

Conducting regular inspections on hoses for wear and tear is essential. Frayed or cracked hoses should be replaced immediately to prevent accidents. Maintaining compatibility ensures both safety and equipment longevity, delivering reliable performance every time.

Recommended Hoses for Common Pressure Washer Models

For top performance and compatibility, specific hose types enhance functionality across various models. For example, a 25-foot or 50-foot hose with a diameter of 1/4 inch suits most consumer-grade devices like those from Karcher and Simpson. If your equipment handles higher flow rates, a 3/8 inch diameter will optimise water delivery.

Brands like Sun Joe and Ryobi pair well with reinforced thermoplastic hoses, providing durability and flexibility. For heavy-duty models such as those made by Generac, a rubber hose is advisable, as it withstands higher pressures more effectively.

Additionally, for electric units, lightweight options are preferred; however, for gas-powered counterparts, a sturdier design with an appropriate rating ensures reliability. Non-marring features are spaciously available, protecting surfaces during operation.

Specific recommendations include the Flexzilla Pressure Washer Hose for ease of use and durability, and the Simpson MorFlex, which offers excellent bend radius and kink resistance. Always consider the compatibility with fittings and connectors specific to your model; this simplifies the connection process and minimizes leaks.

When selecting a hose, verify the PSI and GPM ratings to align with your washer’s specifications for optimal results. Following these guidelines will enhance the cleaning experience significantly.

FAQ:

Can I use any type of garden hose with a pressure washer?

Not all garden hoses are suitable for use with pressure washers. It is recommended to use hoses that are specifically rated for high pressure to avoid damage or leaks. Standard garden hoses may not withstand the pressure and could burst or kink during use. Look for hoses that are reinforced and have a PSI (pounds per square inch) rating that meets or exceeds the requirements of your pressure washer. A good option is a rubber or PVC hose designed for pressure washing.

What are the risks of using an incompatible hose with my pressure washer?

Using a hose that is not designed for high-pressure applications can lead to several issues. First, an incompatible hose may fail under pressure, resulting in burst hoses, which can cause injury or damage to property. Additionally, if the hose does not fit the pressure washer properly, it can lead to leaks, reducing the overall efficiency of the pressure washer. It could also cause strain on the machine, potentially leading to malfunctions or a shortened lifespan. Always check the specifications of both the pressure washer and the hose to ensure they are compatible.