The operation of a high-pressure cleaning device hinges on an engine that drives a pump. When activated, the engine produces power to draw water from a source, typically a garden hose. This water is then forced through a high-pressure pump, which elevates its pressure significantly, transforming it into an effective cleaning stream.

Critical to its function is the pump type. Axial pumps are common, designed for moderate cleaning tasks, while triplex pumps offer superior performance for more demanding jobs. Understanding the pump specifications will help you choose the right equipment based on your cleaning requirements.

The nozzle is another integral component. It determines the spray angle and pressure of the stream, making it essential to select the appropriate nozzle for different surfaces and cleaning challenges. A narrow cone is ideal for tough grime, while a wider spray suits gentler applications.

Lastly, fuel choice plays a vital role in the efficiency of the engine. Opting for a high-quality fuel ensures consistent performance and longevity, reducing maintenance issues. By comprehending these elements, one can maximise the potential of this equipment for various cleaning tasks.

Functionality of a Petrol-Driven Cleaning Machine

Your best bet for high-pressure cleaning is a robust engine system. It operates by converting fuel into mechanical power, which drives the pump. The engine uses a carburettor to mix air with fuel for efficient combustion. Quick-start features are usually provided to ensure easy ignition. Once running, it generates the necessary pressure for effective cleaning.

The heart of the operation lies in the high-pressure pump. This unit draws water from a connected source, such as a hose or reservoir. It compresses this water, significantly increasing the pressure. You’ll typically find piston or diaphragm pumps in these machines; each type has its advantages depending on the workload.

The next critical element is the nozzle or lance. This attachment controls the water flow and pressure. By selecting different nozzle tips, I can adjust the spray pattern from a narrow jet to a wide spray, catering to various surfaces and types of grime. This versatility makes it suitable for everything from delicate car surfaces to tough driveways.

A fuel tank is also essential, ensuring the engine runs smoothly during cleaning tasks. It’s vital to check fuel levels regularly and use the recommended type for optimal performance.

Safety features are incorporated, such as pressure relief valves, to prevent excess pressure buildup. Regular maintenance is crucial to keep everything running efficiently–I recommend checking filters, hoses, and connections for wear and tear to prolong the machine’s lifespan.

Understanding the Engine Functionality

The engine in a high-pressure cleaning machine is the heart of the operation, converting fuel into mechanical energy. This energy drives the pump, producing the high-pressure water needed for effective cleaning. Ensuring the engine runs smoothly is crucial for optimal performance.

Key Components of the Engine

- Fuel System: The fuel tank holds the gasoline, which is drawn into the carburettor where it mixes with air. This mixture then enters the combustion chamber.

- Ignition System: A spark plug ignites the air-fuel mixture in the chamber, creating explosions that push the piston down, converting energy into motion.

- Cooling System: Maintaining temperature is vital. Many engines employ air or liquid cooling systems to prevent overheating during operation.

- Exhaust System: Gas produced during combustion needs to be expelled efficiently. The exhaust system channels these gases away from the engine.

Operational Mechanics

When the engine starts, it goes through a cycle of intake, compression, combustion, and exhaust. Each cycle generates enough power to turn the crankshaft, which is connected to the pump. The pump, in turn, pressurises the water and expels it at high velocity through the nozzle.

Regular maintenance of the engine components is necessary. Frequent checks on the fuel system, spark plug condition, and air filter will ensure the machine remains ready for use. Failure to maintain these parts can result in decreased efficiency and increased wear.

In summary, understanding the engine’s functionality allows for more informed decisions regarding maintenance and use, leading to better longevity and performance of the cleaning equipment.

Components of a Petrol Pressure Washer

Understanding the components is crucial for optimising performance. Essential elements include the engine, pump, nozzle, and housing.

Engine

The engine powers the entire unit, converting fuel into mechanical energy. Look for a robust engine model, typically a 2-stroke or 4-stroke type, as this influences both efficiency and longevity.

Pump

This component pressurises the water drawn from a source, allowing for effective cleaning. The most efficient pumps are axial cam or triplex plunger types. Check for a pump that offers adjustable pressure settings for versatility in various cleaning tasks.

- Axial cam pumps: Ideal for light to medium tasks, ensuring simplicity in design and maintenance.

- Triplex plunger pumps: Best for heavy-duty operations, delivering high pressure and durability.

Nozzle

Nozzles modify water flow, crucial for achieving desired impact. Common types include fan, pinpoint, and rotating nozzles. Selecting the right nozzle size enables control over spray patterns and pressure application.

- Fan nozzle: Great for broader coverage and gentle cleaning.

- Pinpoint nozzle: Suitable for tough stains requiring concentrated pressure.

- Rotating nozzle: Provides a powerful full sweep for stubborn grime.

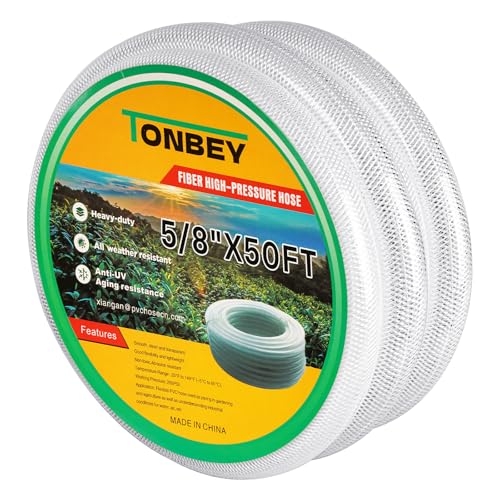

Hoses

High-pressure hoses connect the pump to the nozzle. Inspect for durability, flexibility, and resistance to abrasion. Opt for hoses that can withstand high temperatures and pressures to prevent wear.

Tank

The water tank’s capacity determines the machine’s runtime between refills. Look for larger tanks if extended cleaning sessions are anticipated. Some models offer integrated tanks for added convenience.

Frame and Wheels

A solid frame supports the entire structure, while durable wheels enhance mobility, especially on uneven surfaces. A well-designed chassis simplifies transport and positioning.

Accessories

Additional tools such as surface cleaners, soap dispensers, and brushes can enhance functionality. Consider units that include essential accessories to maximise usability.

Familiarising oneself with each component enables better maintenance and performance, prolonging the lifespan of this equipment and ensuring optimal cleaning results.

How Water Is Pressurised

Water pressurisation occurs through a series of specific mechanisms. At the core, a motor turns a pump, which draws water from a reservoir. The first stage involves the inlet check valve, preventing backflow and ensuring a consistent water supply. Once the pump activates, it compresses the water into a smaller volume, significantly increasing its pressure.

As the water moves through the pump, its kinetic energy rises. The combination of centrifugal force and the design of the pump’s impellers is crucial. These components work to maximise the acceleration of water and create pressure. Different pumps utilise varied designs–some with axial, others with radial impellers–but the goal is the same: to boost pressure effectively.

Pressure Regulation

After compression, a pressure regulator maintains a steady output level. This component adjusts based on the demand for water flow, ensuring the user achieves the intended results without overwhelming the system. By effectively managing pressure levels, the regulator enhances both performance and safety during operation.

Importance of Nozzles

Nozzles play a pivotal role in directing the high-pressure water jet. Each nozzle design offers different spray patterns, impacting cleaning efficiency. A narrower nozzle increases pressure by constricting flow, while a wider nozzle distributes water over a larger area, reducing pressure but covering more ground. Choosing the right nozzle for the task at hand can significantly affect the results.

The Role of the Pump in Pressure Generation

The pump serves as the heart of any high-pressure cleaning equipment, converting mechanical energy from the engine into hydraulic energy. The effectiveness of this component directly affects the output and performance of the device. A quality pump can significantly enhance the flow and pressure of water, which is crucial for tackling tough cleaning tasks.

Types of Pumps

There are primarily two types of pumps used in high-power cleaning devices: diaphragm and axial pumps. Diaphragm pumps rely on a flexible diaphragm to create pressure, ideal for low to moderate tasks. In contrast, axial pumps use pistons to generate higher pressures, making them better suited for rigorous applications.

Pressure and Flow Rate

The relationship between pressure and flow rate is fundamental in understanding a pump’s performance. A higher pressure rating allows for deeper cleansing, while an optimal flow rate ensures sufficient coverage without depleting the water supply too quickly. It’s essential to select a model where these two aspects are balanced to suit your cleaning needs.

Importance of Nozzle Selection for Pressure Application

Choosing the right nozzle is pivotal for achieving optimal results. Each nozzle is designed with a specific spray pattern and flow rate, which directly influences the impact on surfaces. For heavy-duty cleaning tasks, a narrow angle nozzle (like a zero-degree) focuses the force into a powerful jet, ideal for stubborn stains. Conversely, a wider angle nozzle disperses water over a larger area, making it more suitable for gentler cleaning applications.

In practice, using an inappropriate nozzle can cause damage. A narrow spray on delicate materials may lead to scratches or etching, while a broader spray might not remove deep-seated grime effectively. It’s crucial to assess the surface being cleaned before selecting a nozzle.

Refraining from trial and error saves time and material. By understanding the pressure and flow characteristics of each nozzle type, I recommend testing on a small, inconspicuous area first. This approach ensures that the chosen nozzle delivers the desired cleaning power without compromising the integrity of the surface.

Furthermore, nozzle size should align with the machine’s specifications. Using a nozzle that exceeds the recommended pressure limits can lead to malfunctions or decreased efficiency. Maintaining consistent performance hinges on utilising compatible accessories.

Lastly, consider the task at hand; whether it’s grime removal, surface rinsing, or detailing, the right nozzle can significantly elevate the cleaning process. Tailoring your nozzle choice to specific applications maximises effectiveness and efficiency, ensuring thorough, safe results every time.

Common Maintenance Tasks for Optimal Performance

Regularly inspect and clean the air filter to ensure optimal airflow to the engine. A clogged filter can hinder performance and increase fuel consumption. Replace it annually or sooner if it appears dirty.

Oil Changes

Change the oil after every 50 hours of operation or at least once a year. Use manufacturer-recommended oil and check the dipstick to maintain the correct level. Fresh oil lubricates engine components and improves longevity.

Check and Clean the Spark Plug

Inspect the spark plug for wear and carbon buildup. Replace it if necessary, typically every year. A clean spark plug ensures efficient ignition, leading to smoother operation and reduced emissions.

Examining hoses and connections for leaks is critical. Any signs of wear or damage should prompt immediate replacement. Leaks can lead to pressure loss, affecting cleaning efficiency significantly.

Finally, store the equipment in a cool, dry place. Drain gasoline from the tank before long-term storage and run the engine until it stops to clear the fuel system. Proper storage prevents fuel degradation and corrosion within the system.

Safety Measures While Operating a Petrol Cleaning Device

Always wear appropriate personal protective equipment (PPE) including safety goggles and gloves to shield against harmful debris and chemicals. High-velocity water jets can cause severe injuries; safeguard your skin and eyes at all times.

Before starting, ensure the area is clear of bystanders and pets. Maintain a safe distance from others while you operate the machine. This prevents accidents and allows for better focus on the task at hand.

Check the equipment for leaks and loose connections. Regularly inspect hoses, fittings, and the fuel system to avoid unexpected failures during use. A well-maintained cleaner is less likely to pose risks.

Fuel Handling and Storage

Store fuel in a designated, approved container, away from heat sources or direct sunlight. Never attempt to refuel while the engine is running or hot; always allow it to cool down to prevent fires and explosions.

Use only the recommended type of fuel as specified by the manufacturer. Mixing different types of fuel can lead to engine damage and hazardous situations. Handle fuel in well-ventilated areas to minimise exposure to harmful fumes.

Operational Guidelines

Keep the nozzle aimed at the surface being cleaned, avoiding pointing it towards yourself or others. If a blockage occurs, turn off the machine before attempting to clear it. Never attempt to clear blockages with the engine running.

Maintain a firm grip on the spray wand, as the recoil from the water can be powerful. Position your feet firmly to maintain balance, particularly on slippery or uneven surfaces. Be aware of your surroundings, including any overhead wires or obstacles.

Tips for Troubleshooting Common Issues

After years of working with various cleaning machines, I’ve gathered insights that can help resolve frequent challenges. Maintenance is key; ensure the equipment is stored properly and kept clean.

Loss of Pressure

If the device isn’t delivering expected force, check for clogs in the nozzle or hose. Cleaning out debris can restore functionality. Additionally, inspect the connections for leaks, which may reduce performance.

Engine Won’t Start

When the motor refuses to ignite, first verify that there is fuel in the tank. A faulty spark plug can also halt operations; consider replacing it if it appears worn or damaged.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Loss of Pressure | Clogged nozzle or hose, leaks in connections | Clean debris, check for leaks |

| Engine Won’t Start | No fuel, faulty spark plug | Refuel, replace spark plug |

| Excessive Vibration | Unbalanced components | Tighten loose parts |

| Inconsistent Water Flow | Blocked intake filter, air in system | Clean filter, bleed air from system |

Addressing these areas can significantly improve functionality and prolong the lifespan of the machine. Regular checks will prevent many issues before they escalate.