For optimal performance, a standard cleaning unit typically holds around 0.5 to 1 litre of lubricant. The specific quantity can vary depending on the model and manufacturer, so checking the user manual or product specifications is a recommended first step to ensure accuracy.

Synthetic or high-quality mineral options are generally preferable as they provide better lubrication and prolong the lifespan of internal components. When selecting a product, look for items labelled as suitable for high-pressure equipment to maximise performance and efficiency.

Regular checks and changes every 50-100 hours of operation are advisable. This not only ensures your equipment runs smoothly but also prevents unnecessary wear and tear, saving costs in the long run. Make it a part of your maintenance routine to regularly inspect the fluid level and replenish when needed, as low levels can lead to overheating and potential damage.

Recommended Volume for Pump Lubrication

Typically, the capacity for lubrication in these machines ranges from 0.5 to 1.5 litres, depending on the specific model and manufacturer. Always refer to the user manual for the exact required amount to ensure optimal performance and longevity.

Choosing the Right Type of Lubricant

When selecting lubricant for your device, synthetic or petroleum-based options are commonly advised. Synthetic types tend to offer better temperature resistance and wear protection. Again, consult the operational manual for recommendations specific to your model.

Maintenance Frequency

Regular maintenance is key. I suggest checking levels before each use and changing the lubricant every 50 operating hours or annually. Neglecting this can lead to premature wear and costly repairs.

| Model | Capacity (Litres) | Recommended Type |

|---|---|---|

| Brand A Model 1 | 1.0 | Synthetic |

| Brand B Model 2 | 0.75 | Petroleum |

| Brand C Model 3 | 1.5 | Synthetic |

Understanding Pressure Washer Pump Types

For optimal performance, selecting the right type of cleaning device mechanism is crucial. There are primarily two primary categories: axial and triplex pumps. Each has distinct features that cater to various tasks.

Axial pumps are often found in smaller, portable units. They excel in light to medium cleaning jobs and are typically praised for their simplicity and cost-effectiveness. They are easier to maintain, making them suitable for occasional users. However, their durability may be limited compared to their triplex counterparts.

Triplex pumps are engineered for heavy-duty use. They possess three pistons and can endure higher pressure levels, making them ideal for demanding applications like commercial or industrial cleaning. These units are constructed for longevity and can handle continuous usage without overheating or faltering.

When assessing your specific cleaning requirements, consider GPM (gallons per minute) and PSI (pounds per square inch) ratings that vary across these types. Axial pumps generally offer lower PSI and GPM rates, while triplex designs present higher figures, indicating superior cleaning power. This understanding helps in deciding the best fit for your tasks, ensuring efficiency and satisfaction.

Maintenance varies depending on the pump type. Regular checks on seals, valves, and other components extend the lifespan of the equipment. A well-maintained triplex pump can last well over a decade, while an axial model may require replacement sooner due to its design limitations.

Lastly, compatibility with attachments and accessories can influence your choice. Ensure your selected pump type can securely accommodate various nozzles and cleaning aids that fit your intended applications.

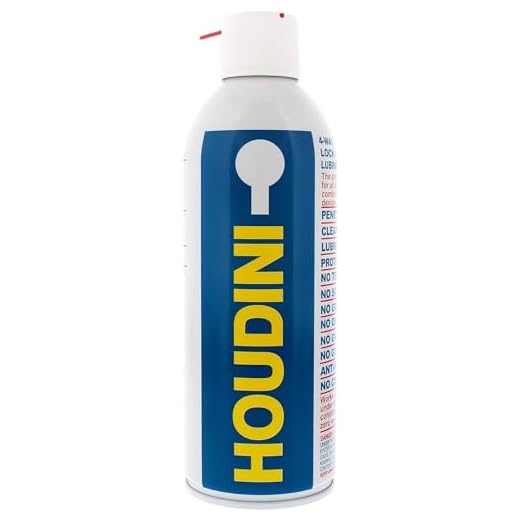

Recommended Oil Types for Pressure Washer Pumps

For optimal operation, select high-quality non-detergent 30-weight lubricant. This ensures maximum performance while reducing wear. It’s crucial to avoid regular motor oil, as additives can lead to foam and eventual damage.

Specific Recommendations

Brands like Mobil, Castrol, and Valvoline offer suitable non-detergent options. Look for products specifically labelled for pumps or compressors to ensure compatibility. Follow manufacturer guidelines for capacity and frequency of change to maintain efficiency.

Environmental Considerations

For those conscious of their environmental impact, consider biodegradable alternatives that meet performance standards without harming nature. Always check for certifications that match your equipment’s requirements.

Checking Fluid Levels in Your Water Cleaning Device

To verify fluid levels in your cleaning device’s motor component, locate the dipstick or inspection plug, usually found at the top or side of the assembly. Remove the dipstick or plug to inspect the fluid’s presence and condition. Clean the dipstick with a lint-free cloth before reinserting it to get an accurate reading.

When examining the fluid, it should appear clear and free from debris or contaminants. If it looks dark or has particles suspended in it, it’s time for a change. Ensure the level is within the recommended range, not exceeding the maximum mark.

If your unit doesn’t have a dipstick, look for a fill plug. When you remove the plug, the fluid should be just below the opening. If it’s low, add appropriate liquid, checking the recommended type in your user manual beforehand.

Regular checks after every use, especially before long periods of inactivity, will help maintain the functionality and longevity of your equipment. This simple task can prevent premature wear and costly repairs down the line.

Signs Your Pump Needs More Lubricant

If you notice any of the following, it’s time to check the lubricant levels in your equipment.

- Unusual noises during operation, such as grinding or rattling, indicate insufficient lubrication.

- Increased vibrations while running can be a clear sign of inadequate lubricant.

- Overheating components, leading to shutdowns, suggest potential issues with lubricant levels.

- Poor performance or reduced pressure can stem from lack of proper lubrication.

- Visible leaks around the housing often signify low lubricant levels and should be addressed immediately.

Regular inspections can prevent damage and extend the life of your equipment. Aim to assess levels routinely, particularly before significant usage.

Oil Change Frequency for Pressure Washer Pumps

For optimal performance, it’s advisable to refresh the lubricant every 50 hours of operation or at least once a season, whichever comes first. Regular checks during heavy use can also ensure longevity.

Factors Influencing Change Frequency

- Operating conditions: In dusty or humid environments, you may need to replace the liquid more frequently.

- Type of work: Heavy-duty tasks result in increased strain, warranting more regular changes.

- Usage duration: Continuous operation may require more frequent attention compared to sporadic use.

Monitoring for Maintenance

Always inspect the lubricant levels and condition before each use. If the liquid appears dark or contaminated, it’s a clear sign for an immediate change. Regular maintenance helps avoid costly repairs and down time.

Step-by-Step Guide to Adding Lubricant to Your Pressure Cleaner Mechanism

Ensure the device is completely powered off and unplugged for safety. Place it on a stable surface where spills can be managed easily.

Locate the filling port. This is typically marked with a symbol or label indicating where the lubricant should be added. If unsure, consult the user manual for specific details related to your model.

Wipe the area around the port with a clean cloth to prevent debris from entering the mechanism during the process.

Pouring the Lubricant

Using a funnel, carefully pour the recommended quantity into the filling port. Be cautious not to overfill; doing so can lead to leaks or operational issues. Refer to previous sections to verify the exact amount required.

After filling, remove the funnel and clean any spillage to keep the exterior clean and free from residue.

Final Checks

Before starting the machine, verify that the filling cap is securely fastened. After this, you can plug the unit back in and turn it on to check for any unusual sounds or leaks. If everything appears normal, the adjustment was successful.

Regularly inspect the lubricant level to maintain optimal functioning. Following these steps ensures longevity and efficiency for your cleaning equipment.

FAQ:

How much oil is required for a pressure washer pump?

The amount of oil needed for a pressure washer pump typically ranges from 0.5 to 1 litre. It’s essential to check the manufacturer’s specifications for your specific model to ensure you’re using the correct amount. Overfilling or underfilling can lead to pump damage, so measuring accurately is important.

Can I use any type of oil in my pressure washer pump?

Not all oils are suitable for pressure washer pumps. Generally, a high-quality detergent oil specifically designed for pressure washers is recommended. Look for oils with an SAE rating of 30 or 40. Always consult the user manual to find out the best type of oil for your model.

How often should I change the oil in my pressure washer pump?

It’s advisable to change the oil in your pressure washer pump after the first 20-30 hours of operation. After that, you should perform an oil change every 100 hours or annually, whichever comes first. Regular changes help maintain optimal performance and extend the life of the pump.

What are the signs that my pressure washer pump needs an oil change?

Signs that your pressure washer pump may require an oil change include dark, dirty oil, unusual noises during operation, or reduced performance. If you notice any of these issues, check the oil level and quality, and consider replacing it to keep your pressure washer functioning effectively.