Begin with draining the existing fuel to avoid contamination. Once emptied, remove the air filter and inspect it for debris. If it’s dirty, clean or replace it to ensure optimal airflow.

Next, locate the small screws securing the fuel supply chamber. Carefully remove these to access the internal mechanisms. It’s wise to keep screws in a small container to avoid misplacement. Following this, gently detach the chamber and observe for any residue or build-up–this can significantly affect performance.

Utilise a soft brush and carburettor cleaner to remove accumulated gunk. Spray the cleaner into the opening and let it sit briefly. Afterward, wipe all surfaces with a clean cloth to ensure everything is free from dirt and grime.

Reassemble the components in the reverse order, taking care to securely fasten all screws. After you’ve returned the system to its original state, refill with fresh fuel. Perform a test start to see if the output has improved. Regular maintenance will prolong the life and efficiency of your machine.

Cleansing the Fuel Delivery System

Begin with draining the fuel tank to prevent spills. Use a suitable container to collect the remaining petrol safely. Once emptied, proceed to remove the air filter assembly, which might be secured with screws or clips. Set it aside for access to the next components.

Disassembling the Combustion Component

Carefully take off the outer casing to expose the workings inside. Ensure you note the placement of each part during disassembly. Detach the float bowl at the bottom of the assembly using a wrench, allowing any residual fuel to drain. Keep track of the screws and small components.

Inspecting and Removing Blockages

With the bowl removed, inspect the needle and seat for any dirt or clogs. Use a fine brush and carburettor cleaner to meticulously remove contaminants from all passages. Pay special attention to jets and ports, as they can significantly affect performance if blocked. Use compressed air to blow through any small openings.

Reassembly and Testing

Once all parts are cleaned and dried, reassemble in the reverse order of disassembly. Make sure each element is securely tightened to maintain proper function. Refill the tank with fresh fuel and replace the air filter. Start the unit to verify that everything operates smoothly without leaks.

Routine Maintenance Tips

To prolong the life of your gas-powered engine, consider using a fuel stabiliser when storing it for extended periods. Regularly check and replace filters and inspect fuel lines for wear. Perform these checks at least once per season if it sees regular use.

Gather Necessary Tools and Materials

Prepare the following items to ensure a smooth process: a set of screwdrivers, including both flathead and Phillips; a socket wrench to remove bolts; and a pair of pliers for handling small parts. A clean work surface is essential, along with a container to keep screws and components organized.

Cleaning Supplies

Procure high-quality carburetor cleaner spray to eliminate residue effectively. Ensure you have a soft brush and a microfiber cloth to tackle tough spots without causing damage. Additionally, consider having compressed air on hand to blow out dirt and debris from hard-to-reach areas.

Safety Equipment

Don protective eyewear and gloves to safeguard against chemicals and small parts. A mask can be beneficial when working with sprays to prevent inhalation of fumes. Always work in a well-ventilated area to maintain air quality during maintenance.

Ensure Safety Precautions Before Starting

Disconnect the spark plug lead to prevent accidental ignition. This is a critical step before undertaking any maintenance or inspection tasks. Ensure the area is well-ventilated to avoid inhaling fumes emitted from fuel or cleaning agents.

Wear appropriate personal protective equipment (PPE). Safety goggles will protect your eyes from debris or cleaning solutions, while gloves shield your hands from chemicals and sharp components. Consider wearing a mask if you are sensitive to fumes or airborne particles.

Check for fuel leaks. Prior to beginning any work, inspect the fuel system for any signs of leaks or spills. Addressing these issues immediately is vital for your safety and the integrity of the machine.

Have a fire extinguisher nearby. Positioned within easy reach, this precaution is crucial when handling flammable fluids. Ensure it is charged and in good condition.

Lastly, ensure that the unit is on a stable surface. Working on uneven or unstable ground can lead to accidents, particularly when dealing with equipment that involves fuel and moving parts.

Remove the Carburetor from the Pressure Washer

Disconnect the fuel line from the tank. Use pliers to pinch the clamp and slide it back to prevent spillage. Be prepared with a rag to catch any residual fuel.

Next, locate the screws securing the assembly to the engine. Typically, these are found at the side or bottom; use a screwdriver to remove them. Keep these screws in a small container for easy retrieval.

Once unscrewed, gently wiggle the carburettor to detach it from the manifold. Take care not to damage the gaskets or any attached components. It’s advisable to note the orientation of all connections for reassembly.

Disconnect Linkages and Additional Components

Remove any throttle or choke linkages. These may require a small screwdriver to loosen the retaining clips. Document their positions if needed. Regarding additional components, disconnect any electrical connections, ensuring the wires are clear of sharp objects.

Once everything is detached, carefully pull the assembly away from the engine, making sure no parts get left behind. Place the removed part on a clean surface, ready for your next steps.

Dismantle the Carburetor for Thorough Cleaning

Begin by securing the unit on a stable surface, ensuring that no fuel is left in the tank. Locate the appropriate screws or bolts that hold the assembly in place. Typically, you will find these on the top or sides of the unit. Use a screwdriver or socket wrench to remove them carefully.

Remove Key Components

- Detach the air filter housing if applicable, allowing access to the main components.

- Disconnect the throttle and choke linkages. It’s advisable to take a photo of the connections for reference during reassembly.

- Carefully pull the fuel line away while ensuring no residual fuel spills. Use a container to catch any drips.

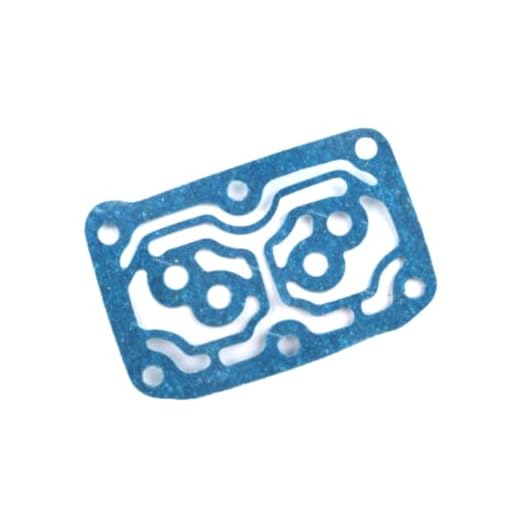

Once the main assembly is free, gently lift the unit from its mounting bracket. Be cautious with any gaskets that may be in place; these should be replaced if damaged during removal. Examine the flywheel and internal components, looking for any accumulated debris that could affect performance.

Inspect and Organise for Cleaning

- Place all removed parts in a clean workspace, organising them methodically to ensure easy reassembly.

- Check for wear on gaskets and seals, as they may require replacement.

- Pay attention to small parts like jets and needles; those can become clogged and may need specific clearing techniques.

A meticulous dismantling allows for a thorough examination and treatment of each component, ensuring optimal functionality when reassembled.

Clean Components with Appropriate Solutions

For optimal results, I recommend using a combination of carburettor cleaner and ultrasonic cleaning techniques. Carburettor cleaners are designed to dissolve varnish, sludge, and build-up, ensuring every passage and jet is free from obstructions. An ultrasonic cleaner offers an efficient way to remove intricate dirt from all components.

Begin by soaking the disassembled parts in a carburettor cleaner. Follow the manufacturer’s instructions for dilution rates if required. Allow the components to soak for approximately 15-30 minutes, ensuring contaminants loosen adequately.

Recommended Cleaning Solution:

| Solution | Use | Notes |

|---|---|---|

| Carburettor Cleaner | Soaking and brushing | Follow label directions for safety |

| Ultrasonic Cleaner | Intricate component cleaning | Ensure appropriate frequency settings |

| Compressed Air | Drying and clearing passages | Use carefully to avoid damage |

After soaking, use a soft-bristled brush to scrub any stubborn deposits from surfaces and passages. Pay special attention to jets and the float bowl. Thorough rinsing with clean water will remove any residual cleaner before drying the components thoroughly.

For delicate parts, an ultrasonic cleaner can provide a thorough cleanse without manual scrubbing. Run the device for a complete cycle to ensure all contaminants are eliminated. After cleaning, inspect each part carefully for any visible damage or wear.

Once dried, consider applying a light coat of lubricant to sliding parts before reassembly–it aids in ensuring smooth operation. After cleaning and preparations, you’ll be well on your way to a fully functional engine system.

Inspect for Wear and Damage during Cleaning

After disassembling the fuel delivery component, carefully examine each part for signs of wear or damage. Look for cracks, corrosion, and any significant dents that could affect performance. Pay special attention to gaskets and O-rings; these often degrade over time and may need replacement.

Check for Clogs and Blockages

Ensure that all channels and passages are clear. Use a small wire or compressed air to remove stubborn debris which might impact fuel flow. If a part appears excessively worn, consider replacing it before reassembly to avoid recurring issues.

Evaluate Fasteners and Mountings

Examine screws, bolts, and mounting hardware for stripping or rust. Damaged fasteners can lead to improper sealing, creating fuel leaks or airflow issues. If any components feel loose or do not fit tightly, it’s best to replace them for optimal functionality.

Reassemble the Carburetor Properly

Ensure that each part is correctly oriented and positioned during reassembly. Pay close attention to the gasket, as its placement affects the seal and functionality of the entire unit.

Steps for Reassembly

- Begin by placing the cleaned and inspected main body of the unit on a clean, flat surface.

- Position the throttle plate carefully, ensuring the spring mechanism is in the correct alignment.

- Install the idle adjustment screw and set it to the manufacturer’s specified position to ensure optimal performance.

- Attach the float assembly, making sure it moves freely and does not stick.

- Securely fasten all screws and bolts, using a torque wrench if necessary, to adhere to manufacturer specifications.

Final Checks

- Verify that all gaskets and seals are intact and properly aligned to prevent leaks.

- Check that the fuel inlet and outlets are unobstructed and positioned correctly.

- Ensure that any external linkage connected to the choke and throttle is functioning smoothly.

Once you’ve completed reassembly, connect the unit back to the mower and ensure all fittings and hoses are secured. This attention to detail will significantly enhance performance and extend the lifespan of your equipment.

Reinstall the Carburetor and Test Functionality

Securely position the assembly back onto the engine, aligning all ports and gaskets correctly. Ensure that the fuel line is reattached firmly without any kinks. Fasten the mounting bolts using a torque wrench, adhering to the manufacturer’s specified torque settings to prevent leaks or vibration loosening during operation.

Reconnect any electrical connectors that were previously detached, taking care to ensure a snug fit. Reattach the air filter housing and any related components, ensuring they are secure and correctly positioned.

After reinstallation, fill the fuel tank with fresh fuel to check for leaks at the fuel line connections. Before starting the engine, inspect for any loose components or forgotten parts. Once everything appears secure, initiate the start process, allowing the engine to warm up for a few minutes.

Monitor the performance carefully, checking for even idling, smooth operation, and absence of unusual noises. If there are irregularities, conduct a thorough re-examination of the installation, focusing on connections and alignments. This step is critical to ensuring optimal functionality and longevity.