The best approach involves utilising a mix of warm soapy water and a soft-bristled brush. Ensure your equipment is disconnected from the power source and the water supply before starting this process.

Begin by filling a bucket with warm water and adding a gentle detergent, suitable for removing grime without damaging the material. Submerge the brush in the solution, ensuring it is wet enough to scrub the interior surfaces. Apply consistent pressure while cleaning, focusing on sections where dirt accumulates more readily.

After brushing, rinse the tubing thoroughly with clean water to remove any soap residue. If clogs are present, consider using a mild pipe cleaner or a flexible, non-abrasive stick to dislodge debris, being careful not to damage the internal lining.

Allow the tube to dry completely before reattaching it to the unit to prevent any moisture-related issues or mould growth. Regular maintenance not only improves performance but extends the life of your equipment.

Cleaning Your High-Pressure Cleaning Tube

Disconnect the line from the machine before starting maintenance. Use a soft brush or cloth to remove debris from the outer surface. For tougher grime, a mild detergent mixed with warm water works well. Soak a cloth in this solution and wipe the exterior, ensuring to follow the natural bends and curves of the equipment.

Next, inspect the interior. If it’s blocked, mix vinegar and water in equal parts and fill the tube. Allow it to sit for 30 minutes to loosen any stubborn residues. Afterward, run water through to rinse thoroughly, ensuring all vinegar and debris are washed away.

Avoid using metal tools or sharp objects as they can damage the tube. Regular checks for kinks or wear are necessary to prolong the lifespan of the tube. Store the equipment in a cool, dry place, away from direct sunlight to prevent deterioration.

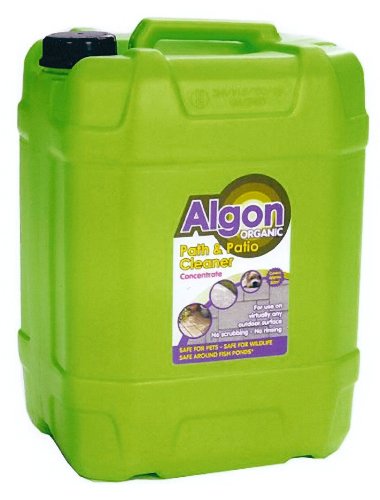

If the inner surface is especially fouled, consider purchasing a dedicated cleaning solution designed for high-pressure systems. Always follow the manufacturer’s instructions when using these products for optimal results.

Gather Necessary Cleaning Supplies

First, acquire a bucket. A standard five-gallon one works well for mixing solutions. Ensure it’s clean and free of debris.

Detergents and Solutions

Select a specific cleaning solution designed for your equipment’s materials. Look for non-corrosive options to prevent damage. If you prefer a homemade blend, a mixture of warm water and mild dish soap can be effective.

Tools and Accessories

Prepare a soft-bristle brush for scrubbing. This helps remove stubborn grime without scratching surfaces. A garden hose with a spray nozzle can assist in rinsing your equipment thoroughly. Additionally, invest in a pair of gloves to protect your hands from chemicals and dirt.

Having these items will streamline the process and ensure better results. Gather these supplies before proceeding with the task.

Disconnecting the Hose Safely

Ensure the unit is completely powered off and disconnected from any electrical source to prevent accidents. Allow the equipment to cool down if it has been recently used. This precaution avoids burns and other injuries.

- Check the water supply; make sure the tap is closed to prevent further water flow.

- Release any residual pressure. Locate the trigger gun and squeeze the handle until no more water emerges. This step is critical for safety.

Disconnect the connector from the machine carefully. Grip both the hose and the machine’s fitting firmly, twisting it gently to loosen. If there’s resistance, avoid forcing it, as this may cause damage.

Handling the Connection Points

Inspect the connectors for any signs of wear or damage. Regularly examine these parts as they can often be the weakest links in the system. Cleaning around the joints ensures a better seal when reassembling.

- If a quick connect fitting is present, squeeze the release tab to detach it smoothly.

- For threaded connections, turn counter-clockwise gently. If it’s stuck, apply lubricant but ensure that you do not apply too much force.

After the removal process, store the hoses in a dry location, away from direct sunlight and extreme temperatures. A proper storage routine extends the life of your equipment and enhances performance during subsequent usages.

Inspecting for Damage and Blockages

Begin with a close examination of the entire length of the tubing. Look for signs of wear such as cracks, kinks, or abrasions. Any visible damage can compromise performance and safety, so consider replacing any severely affected sections.

Next, check both ends of the tube for obstructions. Carefully remove any debris or residues that may accumulate over time. A blockage can severely limit water flow, affecting both efficiency and effectiveness.

Run a thorough inspection by shining a flashlight into the tube. This will help identify hidden blockages or buildup that might not be visible to the naked eye. If you encounter significant hindrances, using a flexible brush can assist in dislodging stubborn materials.

Pay attention to the connectors as well. Look for signs of corrosion or damage that could lead to leaks or pressure loss. Ensure that the attachments are securely fastened to prevent any accidental disconnections during use.

If you notice a persistent blockage that cannot be cleared through visual inspection or basic cleaning, it may be beneficial to consider a professional inspection. Prioritise functionality and safety to ensure optimal operation during your cleaning tasks.

Cleaning the Exterior of the Hose

For a thorough refresh, focus on the outside of the plumbing. Start by preparing a mixture of warm water and mild detergent in a bucket. A sponge or soft cloth will work well for this task.

Immerse the sponge or cloth in the soapy solution and wring it out to avoid excessive water. Wipe down the surface of the plumbing, ensuring you cover all areas, especially any spots with visible grime or stains.

After scrubbing, rinse the exterior with a clean damp cloth to remove any soapy residue. This prevents any buildup that may attract dirt in the future. If stubborn stains remain, consider using a soft-bristled brush for extra scrubbing power.

Dry the exterior with a clean, dry towel. Proper drying helps prevent mould or mildew from forming, especially if the equipment is stored in a humid environment.

Store the apparatus in a shaded area or indoors to minimise exposure to the elements, which can degrade the materials over time.

Regular maintenance of the external surfaces not only enhances appearance but also prolongs the lifespan of the equipment.

| Step | Description |

|---|---|

| 1 | Mix warm water with mild detergent. |

| 2 | Soak a sponge or soft cloth in the solution. |

| 3 | Wipe down all surfaces of the plumbing. |

| 4 | Rinse with a clean damp cloth. |

| 5 | Use a soft brush for tougher stains. |

| 6 | Dry thoroughly to avoid mould. |

| 7 | Store in a shaded or indoor location. |

Flushing the Hose with Water

To effectively purge the tubing, position one end securely in a freshwater source, like a bucket or garden tap. With the other end held upright, allow a steady stream of water to flow through the line. This process helps dislodge any stubborn debris or residues trapped inside.

Turn on the water supply gradually, ensuring a strong, uninterrupted flow. After a few minutes, switch angles and gently shake the tubing to assist in loosening any blockages. This technique also helps in visualising any remaining contaminants as they exit the end of the line.

Continue this method until the outflow is clear and consistent. Once completed, disconnect the water source and inspect the interior for any lingering particles. A thorough rinse will extend the usability of your equipment, enhancing its longevity and performance.

Storing the Hose Properly After Cleaning

To prolong the lifespan of your cleaning equipment’s tubing, proper storage is crucial. After the cleansing process, follow these guidelines to ensure optimal preservation.

Coiling Techniques

- Always coil the tubing without kinks or twists. This prevents damaging bends and allows for easy unraveling next time.

- Use a figure-eight method if it has a longer length. This ensures minimal stress on the material.

Storage Conditions

- Store indoors in a cool, dry environment to avoid prolonged exposure to direct sunlight, which can deteriorate the material over time.

- Avoid damp areas where moisture could lead to mould or mildew.

- Consider using a hose reel or hook to keep the coil secure and off the ground, reducing the risk of accidental damage.

By following these recommendations, you will maintain the integrity and functionality of your cleaning accessories for future use.