Begin with positioning the unit on a stable surface, ensuring it is easily accessible. A well-chosen spot will facilitate smooth operations and prevent unnecessary strain on components. Collect the necessary tools including screws, a mounting plate, and a screwdriver, all of which are crucial for a secure installation.

Next, identify the optimal attachment point, typically located on the side or back of the equipment. Align the bracket accurately to ensure the assembly sits flush against the surface. Use a level to confirm the alignment before marking the drill holes to avoid future adjustments.

Proceed by drilling the previously marked holes, ensuring not to apply excessive force to prevent damage. Secure the plate using appropriate screws, tightening them firmly but without over-torquing. This will provide stability during usage, minimising wear on the assembly and connected components.

Finally, connect the water supply accessory according to the manufacturer’s specifications. Check for any kinks or obstructions in the piping that could hinder performance, ensuring a seamless flow of water during operation. Regular inspection of connections will contribute to longevity and efficiency during usage.

Guidelines for Installing a Rewind Device on a Cleaning Apparatus

First, gather all necessary tools: a screwdriver, adjustable wrench, and appropriate mounting hardware. Ensure you have a compatible rewind device specifically designed for your type of cleaning apparatus.

Find a suitable location on the frame of the machine. Typically, the side or back is ideal, providing easy access without interfering with other components. Measure the distance meticulously to ensure proper alignment with the rewind device holes.

| Step | Action |

|---|---|

| 1 | Position the rewind device against the frame in the chosen location. |

| 2 | Mark the drill points using a pencil or marker through the rewind device holes. |

| 3 | Drill holes into the frame at the marked points, ensuring to use a drill bit that matches your mounting hardware. |

| 4 | Align the rewind device over the drilled holes, inserting screws or bolts through the brackets. |

| 5 | Tighten the screws or bolts securely without over-tightening, which may strip the screws or damage the frame. |

After securing the rewind device, connect the cleaning line as per the manufacturer’s instructions. Ensure that it winds smoothly and does not interfere with the operation of the apparatus.

Finally, perform a test run. Check for stability and functionality. If everything operates smoothly, your installation is complete. Regularly inspect the connection point to ensure everything remains secure over time.

Choosing the Right Hose Reel for Your Pressure Washer

For optimal performance, I recommend selecting a wind-up storage system that balances durability and ease of use. Look for models crafted from high-quality materials like heavy-duty plastic or steel, as these will withstand outdoor conditions.

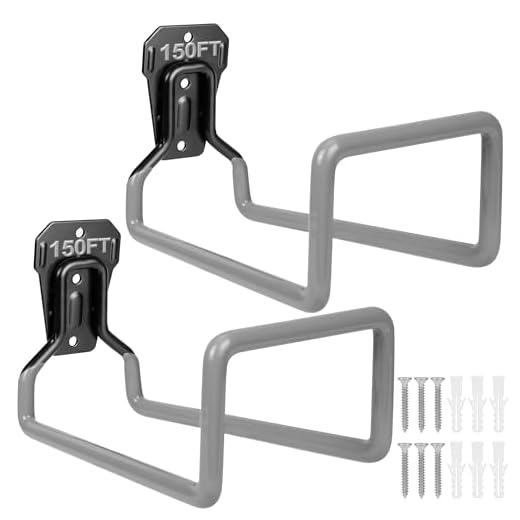

Prioritise the capacity. A unit that accommodates at least 150 feet of tubing is ideal for most tasks. Ensure compatibility with your existing equipment to avoid frustrating gaps during operation.

Consider the mounting mechanism as well. Options include wall-mounted and portable configurations. If you prefer mobility, a portable unit with a sturdy handle will serve you well, while wall-mounted options offer space-saving solutions for tight areas.

Pay attention to the winding mechanism. Automatic rewind features can save time, while manual options can provide more control during storage. Additionally, examine the swivel capability; a unit that rotates smoothly prevents kinks and tangles in your line.

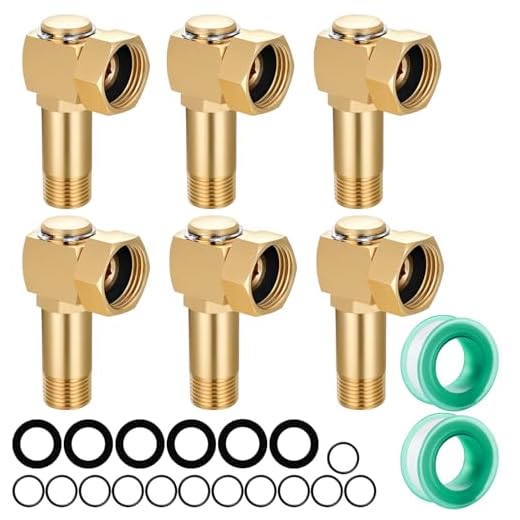

Look for accessories such as connectors and adapters, as these will enhance flexibility and compatibility with various attachments. Having the right fittings ensures seamless transitions between tasks without extra hassle.

Finally, check customer reviews and product warranties. Feedback from users gives insight into long-term durability and performance, while a good warranty indicates manufacturer confidence in their product.

Gathering Necessary Tools for Installation

Ensure you have the following equipment ready for a smooth installation:

- Drill and Drill Bits: A power or manual drill will be essential. Choose appropriate metal or masonry bits depending on the surface.

- Screwdriver Set: Both flathead and Phillips screwdrivers will be necessary for various screws you may encounter.

- Wrench or Socket Set: Adjustable wrenches or a set of sockets will aid in tightening bolts securely.

- Measuring Tape: Accurate measurements of distances and dimensions are critical for correct placement of the bracket.

- Level: A spirit level ensures everything is installed straight, avoiding issues with functionality.

- Pencil or Marker: Use this for marking holes and guide points before drilling.

- Safety Gear: Safety glasses and gloves should be worn to protect against debris and sharp edges.

Optional Tools

- Stud Finder: Useful if mounting onto drywall or wood to locate studs for added support.

- Hook or Clamp: For holding the assembly in place temporarily while securing.

- Additional Hands: Having someone to assist can make the process quicker and ensure accuracy.

By preparing these items beforehand, you will streamline the installation process and enhance the outcome of your project.

Preparing the Pressure Sprayer for Hose Mounting

Before proceeding, ensure the machine is turned off and unplugged from the power source to eliminate any risk of accidental activation. Remove any existing attachments or accessories from the nozzle and connectors to create a clean, unobstructed area for installation.

Evaluate the surface where the accessory will be positioned. Look for sturdy and flat areas on the unit that can support the additional equipment without compromising stability. It’s advisable to avoid corners or areas with moving parts that could interfere with the operation.

Next, inspect the pressure sprayer for any signs of wear or damage. Check the connection points and hoses for cracks, leaks, or other issues that could hinder performance. Address any problems before continuing with the setup.

Gather the assembly manual for your sprayer if available. This document often contains valuable diagrams and instructions specific to your model, ensuring accuracy during the installation process. Familiarising yourself with your sprayer’s layout will help streamline the integration of the new component.

After reviewing the manual, create a designated workspace around the appliance. Clear any clutter from the area to allow easy movement during the installation. This preparation will make the process smoother and help avoid potential accidents.

Double-check that you have all necessary tools at hand before starting. Ensure you’re equipped with the appropriate drill, screws, and other hardware that may be required for securing the new accessory. This thorough readiness will save time and prevent unnecessary interruptions once you begin.

Identifying Mounting Locations on the Pressure Cleaner

Begin by examining the frame of your unit for a suitable spot. The ideal location should allow for easy access to the rewind mechanism while keeping the unit stable during operation. Look for flat surfaces that can support additional weight without compromising balance.

Considerations for Placement

Avoid areas near vents or components that generate heat, as these could affect performance or lead to wear over time. Check any existing attachments; the new accessory should not obstruct them. Take into account the orientation of your garden sprayer. Ensure that the installation does not hinder mobility or storage.

Use of Mounting Templates

If available, utilise mounting templates provided by the manufacturer. These can guide accurate positioning and help determine drill hole placements. Before committing to any location, I recommend a dry-fit test with the mounting bracket. This step verifies that the intended position is practical for both usage and aesthetics.

In my experience, taking the time to carefully assess and select the right installation spot saves significant hassle later on during operation.

Securely Attaching the Hose Reel to the Pressure Washer

First, ensure that the fitting brackets line up perfectly with the attachment points on the cleaning unit. Use a level to confirm that everything is straight before securing it in place.

Next, insert the bolts provided with your reel through the mounting brackets and into the designated holes on the equipment. It’s advisable to use a washer on each bolt to distribute pressure evenly, preventing any stress that could cause damage over time.

Tighten the bolts firmly, ensuring that the assembly holds securely against any vibrations during use. A socket wrench typically offers better leverage than a screwdriver, and I recommend checking the tightness again after conducting initial runs with the unit.

For added stability, applying a thread-locking adhesive to the bolts can provide extra assurance against loosening during operation. This allows for easier removability in the future but keeps everything secure while in use.

Lastly, if the model allows, consider reinforcing the connection with additional mounting straps or brackets in strategic locations to enhance stability further. This approach is particularly beneficial if you anticipate heavy usage or are working on uneven surfaces.

Connecting the Hose to the Pressure Washer and Reel

Begin with ensuring a tight seal between the connector and the inlet of the cleaning device. It is essential that the connection is secure to prevent any leaks. Check the O-rings on both ends before attachment; replacing them can eliminate potential issues.

Next, thread the end of the tube through the guide on the storage unit to maintain organisation. This method simplifies access and reduces wear on the tubing. Ensure that the tube extends smoothly without twists that might restrict water flow.

If the length of the tube exceeds what is necessary, consider using a cutting tool designed for this purpose. Measure accurately before cutting; the compromised section can lead to inefficient operation or further complications down the line.

After connecting the pipe to the storage mechanism, check the alignment. Any angled connections may result in unnecessary strain. Correct alignment ensures that pressure remains consistent throughout usage.

- Secure all fastenings before starting the system.

- Turn on the water supply to check for leaks.

- Adjust as necessary if you detect any drips at the connection points.

It is prudent to test the setup by running the equipment on a low setting initially. Gradually increase to the desired pressure while monitoring for any functional issues. This approach allows for early detection of problems that might arise, ensuring everything operates harmoniously.

Testing the Setup for Leaks and Functionality

After completing the installation, it’s imperative to check for leaks and ensure everything operates correctly. First, turn on the water supply and run the unit without engaging the trigger on the gun. Examine all connections carefully; leaks can often appear at the joining points. If you notice any water escaping, tighten the fittings slowly with a wrench until the dripping stops.

Pressure Check

Next, switch the unit on to check its operation. Engage the trigger for a few seconds. Monitor the flow and listen for any unusual noises that might indicate issues with the pump or motor. A steady stream of water without fluctuations shows a well-functioning system.

Ensure Proper Recoil

Once satisfied with the connections, retract the line using the built-in mechanism. This test helps determine if the assembled apparatus rolls back smoothly without resistance or jams. If there’s struggle, inspect for tangles or misalignments.

In conclusion, adhering to these testing procedures will confirm a reliable setup, paving the way for effective usage and maintenance of your cleaning system. Regular checks will prolong its service life and performance.