Using a water softener or descaling agent is your most effective route to improving your cleaning results. Incorporating these solutions will significantly enhance the performance of your equipment, ensuring longevity and efficiency. I’ve tested various methods over the years, and this straightforward approach consistently provides the best outcomes.

Installing a whole-house water softening unit can be an investment but pays off in the form of cleaner surfaces and less build-up in your machinery. If that’s too large a commitment, consider a portable descaling system that can be placed directly at the source of your water supply. These systems are often compact and easy to install, making them a practical option.

Another strategy you might want to consider involves using filter cartridges specifically designed to treat alkaline water. I’ve found that switching to these cartridges in your inline filter can dramatically reduce mineral content, thus preventing the scaling that hampers performance. Regular maintenance and replacing these filters as needed will keep your equipment operating at its best.

Adjusting the temperature of the water can also aid in this aspect. If your device allows for heated water, maintaining a higher temperature can help dissolve minerals and reduce build-up before it settles. Combine this with the above methods for a comprehensive approach to optimal cleaning power.

Methods to Improve Quality of Supply for Cleaning Equipment

.jpg)

Implementing a water softening system is a practical solution. Consider using a reverse osmosis unit, which effectively diminishes minerals causing scale. This approach provides purified water, enhancing the efficiency of your cleaning equipment and extending its lifespan.

Alternate Techniques for Better Performance

Another way to enhance the quality of the fluid is through the application of chemical softeners. These substances, when mixed correctly, neutralise the minerals present. Ensure to follow the manufacturer’s recommendations on dosage to prevent potential damage to your gear.

Regular Maintenance and Monitoring

Establishing a routine for checking the quality of the liquid can alert you to any changes requiring immediate action. Utilize a simple test kit to regularly monitor mineral levels. Keeping track will help anticipate any necessary adjustments, ensuring optimal performance during usage.

| Method | Description | Benefits |

|---|---|---|

| Reverse Osmosis | Removes impurities through a semi-permeable membrane. | Produces high-quality supply, extending equipment lifespan. |

| Chemical Softeners | Neutralises minerals when mixed in with regular fluid. | Cost-effective and easy to implement. |

| Regular Testing | Monitoring mineral levels with a testing kit. | Prevents unexpected issues and ensures longevity. |

Understanding Water Hardness and Its Impact

Examining the mineral composition of H2O reveals significant implications for cleaning tasks. Elevated levels of calcium and magnesium lead to challenging conditions during usage. The following aspects highlight the consequences of these mineral concentrations:

- Scaling: Residue buildup on equipment components hinders performance, leading to potential malfunctions over time.

- Detergent Efficiency: Quality of cleaning agents diminishes, as minerals impede their effectiveness, requiring increased concentrations for satisfactory results.

- Surface Damage: Hard minerals can scratch or etch surfaces being cleaned, risking damage to delicate materials.

- Operational Costs: Higher maintenance and repair needs arise from mineral accumulation, directly affecting long-term expenses.

Understanding these factors is crucial for maximising the longevity and efficiency of cleaning devices. Regular monitoring of mineral levels in your source can provide insights to mitigate potential issues. Consider investing in filtration systems that target these minerals precisely. This ensures optimal operation and prolongs both the equipment’s life and effectiveness during usage.

Informed choices regarding the quality of the liquid used not only enhance performance but also result in an overall better cleaning experience, saving time and effort.

Measuring Hardness Levels at Home

To assess the mineral content in your supply, use a simple test kit readily available from home improvement stores. These kits typically contain test strips or liquid reagents that provide immediate feedback on the concentration of alkaline minerals.

Fill a clean container with your tap fluid, dip the strip or follow the kit instructions, and compare the resulting colour to the provided scale. A range of values, commonly marked in parts per million (ppm), will indicate whether the fluid is soft, moderately hard, or very hard.

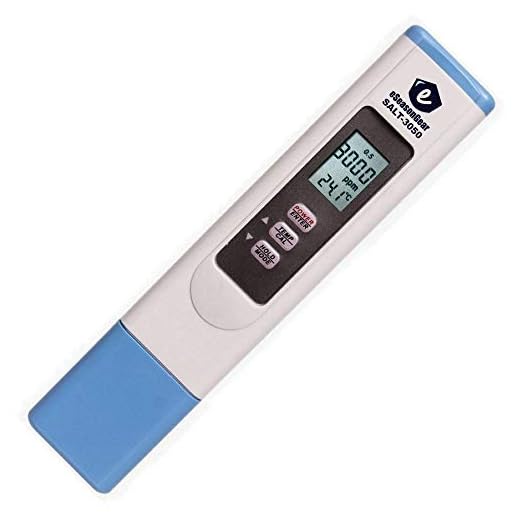

If you prefer a more precise approach, consider utilising a digital tester. These devices measure the conductivity of the liquid, converting it into a hardness reading. They’re easy to use and provide instant results, making them a worthwhile investment for anyone intending to maintain optimal conditions for their cleaning equipment.

For a quick DIY alternative, place a few drops of liquid soap in a clear container filled with a sample. Should it produce excessive bubbles or fail to lather, the presence of minerals is likely high.

Regular measurement is advisable, especially if you notice diminished performance with your equipment. This ensures you can take appropriate action if the mineral levels rise beyond a manageable point.

Using Water Softening Products for Pressure Washers

Apply commercial softening agents tailored for high-pressure cleaning devices. These products can significantly enhance performance by preventing mineral build-up that often leads to malfunction. Many formulations come in liquid or granulated forms, easily blendable with the source fluid.

Select a softening agent compatible with your specific model. Consult the manufacturer’s guidelines to ensure proper application. Adhere to the recommended dosage to avoid over-soffing, which can result in foaming and reduced pressure.

Monitor the output quality after implementing a softening product. A marked improvement in cleaning efficiency usually indicates successful integration. Regular maintenance of filters and nozzles is also crucial, as softened mixtures can still leave residues if not properly managed.

You may also consider portable softeners designed for immediate use. They connect directly to the supply line, instantly changing the characteristics of the liquid entering your cleaning equipment. This solution becomes particularly useful for mobile cleaning operations.

Keep an inventory of softening products to maintain consistent results. Storing them correctly will prevent degradation and ensure optimum performance when needed. Each product might vary in effectiveness, thus experimentation may be required to find the ideal choice for your specific situation.

Implementing a Reverse Osmosis System

This method is unparalleled for achieving optimal purity in the liquid used with your washing equipment. A reverse osmosis system effectively removes a high percentage of dissolved solids, including the minerals that contribute to scale buildup.

To install, select a unit rated for residential use that suits your flow needs. Most systems consist of multiple filters, including a pre-filter, a membrane, and a post-filter. Ensure that each component is of good quality to maximise removal efficiency.

Connect the system to your existing plumbing, allowing it to draw from your main supply. Installation typically involves placing a tank under the sink or in an accessible location, as the processed liquid will be stored there until needed. Make sure to follow the manufacturer’s instructions for wiring and connections.

Regular maintenance is crucial. Replace filters according to the recommended schedule, usually every 6 to 12 months, to ensure optimal performance. This upkeep will prevent clogging and irreversible membrane damage, guaranteeing a steady supply of purified liquid.

Ultimately, this system not only enhances the functioning of your equipment by providing optimal liquid quality but can also extend its lifespan considerably, reducing potential repair costs in the long run.

Regular Maintenance Tips for Pressure Washers

Replace the oil regularly. Every 50 hours of operation or at least once a season, change the oil using the type specified in the manual. It ensures optimal performance and prevents engine wear.

Inspect and clean the filters frequently. Clogged filters can cause damage to the pump. Remove and rinse them under water, allowing them to dry thoroughly before reinstallation.

Check hoses and connections for leaks. Periodically examine the hoses for cracks or bulges. Replace any damaged sections immediately to maintain pressure and prevent accidents.

Use a protective cover when not in use to guard against environmental factors. This simple step prolongs the life of the equipment and keeps it clean.

Test the nozzle condition. Worn or clogged nozzles can hinder performance. Clean or replace them as necessary to ensure effective cleaning.

Drain the pump before storage. To avoid freeze damage, especially in colder climates, remove any remaining water by draining the unit thoroughly.

Store in a dry, cool environment, away from extreme temperatures. Ensure the equipment is stored upright to avoid any potential fluid leaks.

Lastly, keep the user manual handy for reference on specific maintenance requirements. Adhering to the guidelines laid out will enhance longevity and functionality.

Comparing Cost-Effective Solutions for Hard Water Issues

Utilising vinegar as a mild acid can effectively combat mineral buildup. By mixing one part vinegar with two parts distilled water, you can create a solution that cleans the components of your cleaning device. Regularly rinsing internal parts with this formula helps maintain performance without incurring high costs.

Commercial Products

Several brands offer descalers tailored for cleaning machines. These products, typically citric acid based, are formulated to dissolve mineral deposits and can be efficient. When selecting a commercial descaler, check for compatibility with the equipment material to prevent damage.

DIY Solutions

Crafting a homemade softening solution with baking soda and water creates an alkalising effect that counteracts mineral deposits. Using a ratio of one tablespoon per gallon can soften incoming fluid, which is particularly beneficial during longer cleaning sessions.

Using these economical alternatives ensures optimal performance without breaking the bank, providing an efficient way to maintain equipment longevity.