If you find yourself faced with unsightly layers of pigment on your masonry, consider utilizing scraping tools combined with a solvent solution for optimal results. This method allows for precise control, reducing the risk of damage to the substrate while addressing the issue at hand.

A good starting point is to gather your materials. An industrial-grade paint stripper can be quite effective; ensure it is compatible with the type of coating used previously. After applying the stripper according to the manufacturer’s instructions, give it time to work–usually around 30 minutes to an hour.

Once the solution has taken effect, use a stiff-bristled brush or scraper to start lifting the loosened substance. Always work in small sections to manage progress and maintain a cleaner working area. For tougher spots, a heat gun can assist in breaking down the stubborn residue, though caution is essential to avoid overexposure of the surface.

After the bulk of the coating has been lifted, a thorough rinse with clean water should follow. A sponge or cloth can aid in removing any remaining residue. For the final touch, a masonry cleaner can help restore the natural appearance of the material.

Effective Methods to Strip Coating from Masonry

Start by applying a chemical stripper specifically designed for tough surfaces. These products penetrate the coating, breaking down its bonds. Carefully follow the manufacturer’s instructions, ensuring proper ventilated conditions. Use a brush to work the stripper into the crevices. Allow it to sit as directed, then proceed to the next step.

Utilising Scrapers and Brushes

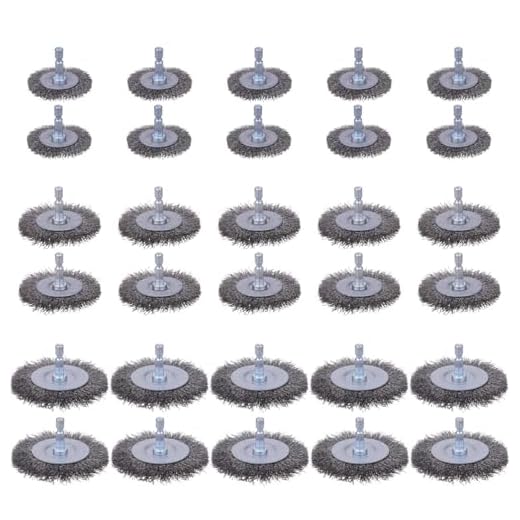

Once the product has activated, use a sturdy scraper or putty knife to lift the softened layer. A wire brush is beneficial for tackling stubborn areas and getting into textured surfaces. Be patient; it may require several passes to achieve a clean result. Keep a bucket of water nearby for rinsing off any residue.

Natural Alternatives

If chemical solutions aren’t suitable, consider a mixture of vinegar and baking soda. Combine equal parts to form a paste, apply to the surface, and let it sit for a short period. The natural acidity helps to break down the surface layer. Scrape with a brush, and repeat if necessary for tougher spots.

Always wear protective gear, such as gloves and goggles, to safeguard against splashes or any debris during the process. After achieving the desired clean finish, thoroughly rinse the area to remove any remaining chemicals or residues.

Understanding Different Types of Coatings on Masonry

The type of coating on masonry significantly influences the approach needed for its removal. Here are key categories to consider:

1. Oil-Based Coatings

These are typically durable and create a glossy finish. Their removal requires solvents like mineral spirits or dedicated paint strippers. It’s crucial to use protective gear due to potential fumes. Test a small area first to determine effectiveness.

2. Latex or Water-Based Coatings

These are easier to work with, often responding well to warm, soapy water or vinegar solutions. A scraper or stiff brush can aid in loosening the material. Rinse thoroughly after application to prevent residue buildup.

3. Epoxy and Similar Coatings

This type is especially resilient and resistant to chemicals. A specialized epoxy remover may be necessary. Follow the manufacturer’s instructions and ensure proper ventilation during the process.

4. Textured or Spray-On Coatings

Textured finishes can complicate matters. A combination of wire brushing and chemical strippers can effectively break down the layers. Be cautious as this approach can potentially damage the underlying surfaces.

5. Historical Layers

.jpg)

In older properties, multiple layers might exist, each requiring unique approaches. A test patch can help identify the best method for your specific scenario.

- Observe the finish: Smooth, glossy or rough, matte surfaces can indicate either oil-based or latex coatings.

- Check for adhesion: The resistance to scratching can provide clues about the coating’s chemical composition.

- Determine age: Older layers might require gentler methods to avoid damage.

Evaluating these aspects allows for an informed strategy in tackling the task ahead, ensuring you select the right products and methods to achieve optimal results while preserving the integrity of the brick structure.

Selecting the Right Tools for Paint Removal

For effective stripping of layers clinging to masonry, the right tools make a significant difference. Start with a handheld scraper or putty knife. Opt for a metal one for resilient surfaces, ensuring you can tackle tougher spots. A variety of sizes allows for precision, especially in corners or intricate designs.

Solvent-Based Options

Utilising chemical solvents can expedite the process. Acetone and methylene chloride are strong contenders. Always test a small area to observe interaction with the surface. Equip yourself with safety goggles and gloves to protect against harsh chemicals.

Manual Abrasion Tools

Sandpaper, specifically coarse grits such as 60 or 80, can be beneficial for stubborn areas. A sanding block provides added control. For larger sections, consider using a hand-held rotary tool equipped with a brush attachment. This will allow you to tackle wider areas while maintaining precision.

Using Chemical Strippers Safely and Effectively

Select a gel or liquid chemical stripper specifically designed for masonry surfaces. These products penetrate the coating effectively while minimising damage to the substrate. Before application, ensure the area is well-ventilated. Open windows and use fans to circulate air. This step is crucial in preventing inhalation of harmful vapours.

Always wear appropriate personal protective equipment (PPE). This includes gloves, safety goggles, and a mask to protect your skin and respiratory system from harsh chemicals.

Application Tips

- Test on an inconspicuous area first. Apply a small amount and wait the recommended time to see the effect on the surface.

- Use a brush or roller for even application. Aim for a thick layer, as this will improve penetration.

- Follow the manufacturer’s instructions closely regarding dwell time–this is the time the stripper needs to sit on the surface for optimal effect.

Cleanup Process

Once the coating starts to lift, use a scraper, plastic if possible, to avoid scratching the surface. After scraping, rinse the area thoroughly with clean water to neutralise the chemicals. Use a stiff brush for stubborn residues.

Dispose of all materials used in accordance with local regulations. Never pour leftover chemicals down the drain or in open areas. Proper disposal is vital for environmental safety.

Regularly check the surface for any missed spots. If necessary, repeat the process in those areas until the desired results are achieved.

Applying Heat to Loosen Paint from Brick

Using heat is an effective way to soften stubborn coatings. A heat gun or a propane torch can provide the necessary temperature to do this. Set the heat gun to a medium setting, or if using a torch, keep it at a safe distance to avoid damaging the underlying masonry.

Steps to Follow

Keep the nozzle a few inches away from the surface and move it steadily across the area. Watch for bubbles or blistering, which indicates the coating is loosening. Once this occurs, employ a putty knife or scraper to gently lift away the softened material.

Safety Precautions

Always wear protective eyewear and gloves. Ensure the work area is free of flammable materials and avoid overheating any sections to prevent cracking or chipping. Maintain good ventilation, especially if fumes are released during the process. Confirm that electricity and gas supplies in the vicinity are safely managed to prevent any hazards.

The combination of heat and careful scraping can yield great results, especially on textured surfaces where other methods may struggle.

Manual Scraping Techniques for Brick Surfaces

Employ a stiff-bristled brush or a metal paint scraper for effective detachment of unwanted coatings. Begin at a corner and work methodically to feel the texture and adhesion of the layer being worked on. Ensure proper grip on the tool to apply consistent pressure without damaging the underlying structure.

Technique for Stubborn Layers

For particularly resistant applications, heat a metal scraper with a heat gun before using it on the surface. This approach softens the coating, making it easier to lift away. Be cautious around joints and mortar to avoid melting or damaging the surrounding materials.

Final Touches and Cleanup

After the bulk of the coating has been removed, utilise a finer tool, like a putty knife, to tackle hard-to-reach areas and edges. Follow up with a thorough vacuuming to remove debris created during the scraping process. Consider applying a cleaning solution for any residual marks to achieve a polished finish.

Cleaning the Brick Post-Paint Removal

Once the surface has been stripped of unwanted coatings, thorough cleaning is essential. Begin with a broom or stiff brush to sweep away loose debris and dust that may have settled during the process.

Thorough Washing

Utilise a bucket of warm soapy water combined with a gentle detergent. A sponge or cloth works well to apply this mixture, scrubbing gently to lift any remaining residues. This step is critical; failure to clean properly can cause future adhesion issues for sealants or paints.

Rinsing Technique

After scrubbing, use a garden hose with a spray nozzle to rinse off the soapy solution. Opt for a gentle spray to avoid dislodging any mortar or causing damage to the newly-cleansed surface. Ensure all soap is removed, as any residue can attract dirt.

For stubborn stains or areas that seem discoloured, consider using a solution of vinegar and water or a baking soda paste, applying it directly to the affected spots. Allow it to sit for a few minutes before scrubbing again and rinsing thoroughly.

Finally, once everything is clean and dry, inspect the surface for any remaining imperfections. Addressing these now can save considerable effort later. If you plan to seal or re-coat, ensure the area is completely dry for optimal adhesion.

Preventing Adhesion of Coatings on Masonry in the Future

Coatings can be troublesome on masonry surfaces, but preventive measures can significantly lower the chances of adhesion. Begin by applying a high-quality masonry sealer before any application. A sealer creates a barrier that reduces the likelihood of coatings bonding firmly to the surface.

Surface Preparation

Properly prepping the surface is paramount. Thoroughly clean the masonry to eliminate dirt, grime, and existing residues. Use a stiff-bristled brush or a broom to ensure that all loose particles are removed. If the surface seems particularly rough, consider using a grinder with a masonry wheel to smooth out any imperfections.

Application of Appropriate Coatings

Select coatings specifically designed for masonry. These products typically contain additives that enhance adhesion while also allowing for easier future removal. Ensure that the selected product is compatible with the type of masonry you are working with. Always refer to the manufacturer’s guidelines for recommended usage.

| Method | Description |

|---|---|

| Masonry Sealer | Prevents moisture infiltration and reduces bond strength of top coats. |

| Surface Inspections | Regular checks for damage or dirt accumulation help maintain surfaces. |

| Proper Tools | Using the right brushes or rollers can affect the even application of coatings. |

| Environmental Considerations | Apply coatings in optimal weather conditions to ensure maximum performance. |

These preventive strategies ensure fewer headaches in the future and prolong the lifespan of your masonry surfaces, saving time and effort during maintenance. Remember that regular inspections and upkeep are key to sustaining the integrity of your masonry investment.