Assess the damage thoroughly before proceeding with any repairs. Look for cracks, punctures, or leaks, as these issues can often be mended with the right materials. A solid option is a high-quality repair tape, specifically designed for hoses. Ensure the surface is clean and dry to optimize adhesion.

Once you’ve identified the problematic section, measure it carefully. Cut a piece of the tape that is at least twice the length of the damaged area. Wrap it around the affected spot with an overlap, ensuring a tight seal. Pay attention to any bends or joints, as these areas are prone to further weaknesses.

If the damage is severe, consider replacing the entire tubing. This process typically involves detaching the old section from the unit and installing a new one that meets the specifications of your equipment. Always refer to the manufacturer’s guidelines for compatibility.

Lastly, after the repair or replacement, test the system at a lower pressure first. Observe for any leaks or issues during the initial operation. Monitoring the repair will ensure long-term functionality and prevent future interruptions during use.

Solutions for Damaged High-Pressure Tubing

First, identify the specific area of damage. A visual inspection often reveals cracks or punctures. If a leak is found, you can use high-quality duct tape as a temporary fix; wrap the tape tightly around the damaged area to prevent further leakage.

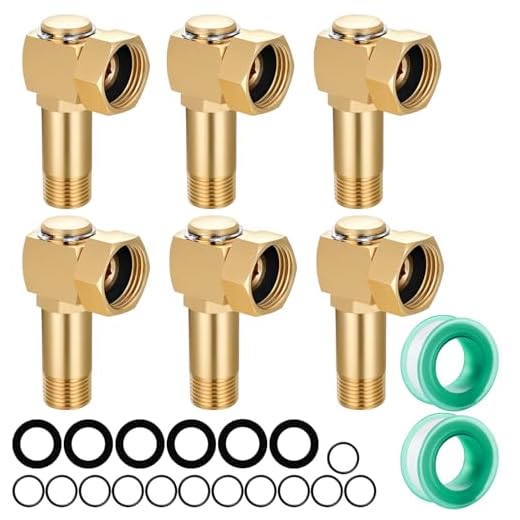

For a more permanent solution, consider replacing the affected section. Measure and cut the damaged length with a utility knife. Purchase a compatible replacement piece from a reliable source. Ensure both ends are clean and free of debris before attaching the new section. A hose connector can be used for a secure fit; simply slide it over the tubing and tighten it with a wrench.

Preventative Measures

Store the tubing properly to prolong its lifespan. Avoid leaving it exposed to direct sunlight or extreme temperatures, which can cause wear over time. Regularly check for signs of damage or wear and replace any worn components promptly to maintain optimal performance.

Maintenance Tips

Flush the system after use to clear out impurities. Ensure that all fittings and connections are tight to prevent leaks. Keep an eye on the seals and gaskets within the connections, as these can wear down and cause issues over time. Replacing these components periodically can save you from larger problems in the future.

Identifying common hose issues

Check for leaks by inspecting the entire length of the tube. Look for any visible cracks, holes, or areas that appear worn or flattened. If you observe any disruptions in the surface, these are likely points for water loss during operation.

Examine the connections at both the machine and the nozzle ends. Loose fittings can result in spray or drips. Tightening these connections may resolve the issue, but if the threads are stripped, replacement might be necessary.

Inspect for kinks and twists. A twisted tube can restrict water flow and cause excessive pressure that leads to bursting. Ensure that any bends are gentle and do not impede the path of fluid.

Monitor for bulges or blisters along the tubing. This can indicate internal damage or weakness, often a precursor to failure. Mark areas of concern for future attention.

Notice any changes in water pressure or irregular spray patterns. These signs often suggest an obstruction, such as debris inside the conduit or a blockage at the nozzle. Flushing the system may help clear away debris.

Lastly, an unusual noise during use–like hissing or rattling–could signal that air is entering the line due to a compromised seal or connection. Identifying and correcting these audible cues can prevent further complications.

Tools Required for Hose Maintenance

For effective maintenance of your cleaning machine’s tubing, a few specific tools are necessary. Gather these items before you begin the task.

Basic Tools

A pair of sturdy scissors or a utility knife is essential for cutting through the damaged sections. Ensure that the blades are sharp for a clean cut. A wrench will be valuable for loosening and tightening any connectors or fittings that may require adjustments.

Additional Equipment

Having hose clamps on hand can be beneficial to secure any temporary or permanent repairs. A tape measure will help in ensuring that your new sections fit properly. Lastly, using waterproof adhesive or sealant can provide extra assurance against leaks.

Step-by-step guide to patching hose leaks

Begin by locating the leak. Carefully examine the entire length of the flexible pipe, paying particular attention to joints and areas where the material appears worn.

Materials Needed

Gather a pair of scissors, a patch kit specifically designed for flexible tubing, a clean cloth for drying the area, and adhesive suitable for the patch. Make sure the patch kit includes pieces of sturdy material that match the diameter of your pipe.

Procedure

Once the leak is identified, clean the surrounding area thoroughly with the cloth to remove any dirt or moisture. Cut a piece of the patch material that is at least 2 inches larger than the damaged area on all sides. Apply the adhesive carefully to both the patch and the pipe around the leak, ensuring a generous coverage.

Firmly press the patch onto the damaged section and hold it in place for a couple of minutes to ensure good adhesion. Allow the adhesive to cure according to the manufacturer’s instructions, usually around 24 hours, before using the equipment again. After the adhesive has set, check for any leaks by running water through the system.

Replacing a damaged hose section

To replace a faulty section of your cleaning device’s tubing, follow these precise steps for an optimal outcome.

First, identify the area that requires attention. Inspect the tubing for any visible damage, such as cracks or abrasions. Once located, measure the length of the damaged segment. Use a measuring tape for accuracy, and note it down.

Gather the following materials before proceeding:

- Replacement tubing of the same diameter and length

- Hose clamps

- Utility knife

- Teflon tape

- Socket wrench

Next, cut the damaged section out using your utility knife. Ensure the remaining parts of the tubing are smooth, and remove any debris or jagged edges. Attach the new section meticulously by sliding it onto the existing tubing. Secure it with hose clamps at both ends to prevent leaks.

Wrap Teflon tape around any threaded connections to ensure a tight seal. Finally, test the assembly by turning on your cleaning device briefly to check for leaks. If everything functions correctly, you’ve successfully replaced the damaged section.

For reference, here’s a summary of the components involved in the replacement:

| Component | Description |

|---|---|

| Replacement Tubing | New section of tubing matching the original diameter |

| Hose Clamps | Used to secure the tubing at connection points |

| Utility Knife | For cutting the damaged section from the tubing |

| Teflon Tape | Ensures a watertight seal on threaded ends |

| Socket Wrench | For tightening any fasteners involved in the connection |

Testing the Repaired Hose for Leaks

After completing the mending process, it’s vital to assess your work for any potential leaks. This ensures the integrity of the fix and confirms that your equipment operates safely and effectively.

Preparation Steps

- Reconnect the sections as needed, ensuring all fittings are secure.

- Place the assembly in an area where any leaking water can be observed easily.

- Fill a bucket or reservoir with water to supply the unit.

Leak Detection Method

- Turn on the electric supply and activate the cleaning device as per manufacturer’s instructions.

- Observe the repaired section closely while the device runs. Check for any signs of water escaping.

- If visible drips or sprays occur, take note of the location for further action.

- For a more thorough assessment, use a cloth to gently apply pressure around the patched area. This can help reveal minor leaks that might not be immediately visible.

If leaks are detected, address them by reinforcing the patch or considering alternative solutions. If everything is confirmed dry, you’re ready to put your equipment back into operation.

Preventive measures to extend hose life

Regular maintenance is vital for longevity. Start by inspecting the equipment regularly for signs of wear or damage.

Storage tips

- Always coil the tubing properly after each use. Avoid cramming or twisting as this may create weak points.

- Keep in a cool, dry place away from direct sunlight. UV rays can degrade the material over time.

- Utilise a protective cover or bag to shield it from environmental factors.

Usage practices

- Avoid dragging the line over rough surfaces that may cause abrasions.

- Ensure all connections are secure before operation to prevent leaks and stress on the lines.

- Stay aware of kinks during use, as they can lead to pressure build-up and ultimately failure.

Utilising these strategies will significantly enhance the lifespan of your cleaning line, ensuring reliable performance throughout its service. Regular checks and care are your best allies in preventing issues before they arise.