If your cleaning apparatus handle is leaking, the most effective solution involves replacing worn-out seals or O-rings. Begin by disassembling the handle using the appropriate tools, typically a screwdriver or wrench, depending on the make and model. Carefully set aside any screws or components to avoid losing them during the process.

Inspect the internal seals for signs of wear or damage. These rubber or plastic components often deteriorate over time, leading to leaks. Measure the old seals to ensure you acquire the correct replacements. Many hardware stores stock these parts, but you can also find them online tailored to your specific equipment’s model.

Once you have the new seals, install them carefully, ensuring they fit snugly in their designated grooves. Reassemble the device, double-checking that all components are securely fastened. Finally, conduct a test run to ensure that any leakage has been successfully addressed. This straightforward approach can greatly extend the lifespan of your cleaning machinery.

Repairing a Dripping Cleaner Launcher

Begin with the O-ring. Remove the trigger assembly and inspect the O-ring for wear or damage. If it appears cracked or flattened, replace it with a new one of the same size. Be sure to lubricate the new O-ring with a silicone-based grease before installation to ensure a tight seal.

Next, examine the connection points where hoses and fittings attach. Loose fittings can cause significant leaks. Use a wrench to tighten any loose connections, but ensure not to over-tighten, as this can cause further damage. If you find any cracked or worn fittings, replace them as necessary.

Clean the internal components thoroughly. Build-up of debris can affect the seal and cause leaks. Use a soft cloth and a suitable cleaning solution to remove any residue inside the assembly. Rinse well and allow to dry before reassembly.

If the leaks persist, check the internal valve assembly. Over time, these valves can wear down and fail to seal properly. Remove the valve and inspect it for any signs of damage. If defective, replace it with a new one recommended by the manufacturer.

Finally, after reassembling the components, test the unit at low pressure first. Observe for any leaks before increasing the pressure to full operation. This ensures that all connections are secure and the components are functioning correctly. By following these steps, I’ve successfully resolved issues with similar tools in the past.

Identifying the Source of the Leak

Start with a visual inspection. Check the connection points for signs of wear or damage. Pay particular attention to:

- Hose fittings: Look for cracks or loose connections that could be causing fluid to escape.

- Nozzle area: Debris accumulation can lead to improper sealing. Cleaning this section is essential.

- Trigger mechanism: Examine the pivot points and seals; these components are common failure zones.

Next, perform a pressure test. Attach the nozzle and run your equipment. Observe the discharge closely for any emerging moisture. This will help you pinpoint the exact location of the leak.

Don’t forget to examine internal seals. If you notice fluid leaking from the gun itself, the internal seals might be compromised. Dismantling the unit may be necessary to assess their condition accurately.

Finally, always check for worn-out components or rubber gaskets. If these parts are hard or brittle, they’ll fail to create a proper seal. Replacing them may resolve the issue.

Gathering Necessary Tools and Materials

Gather the following items to ensure a smooth process: a set of screwdrivers (both Phillips and flathead), adjustable wrenches, a pair of pliers, and a utility knife for precise cutting of seals or hoses. These tools provide the versatility needed to tackle various components of the device.

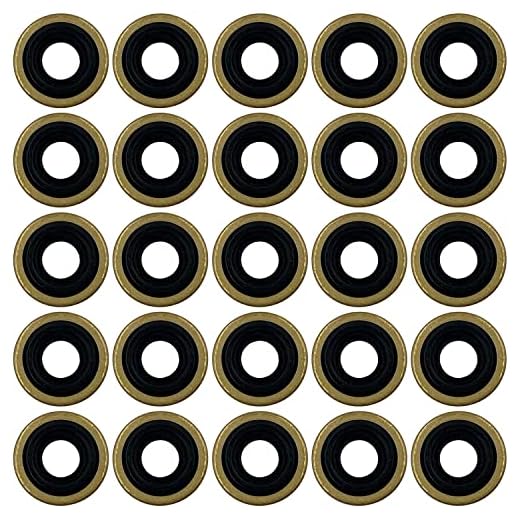

Next, collect replacement parts such as O-rings or gaskets tailored to your particular model. Make sure to check the specifications, as different brands may require unique sizes. Consider purchasing a complete seal kit to cover potential future issues as well.

A cleaning solution can assist in removing grime and debris from the interior, ensuring a thorough inspection without hindrances. Opt for a non-corrosive cleaner to protect components during maintenance.

Don’t forget safety equipment: goggles for eye protection and gloves to safeguard your hands from sharp edges and chemicals. A drop cloth can help contain any mess while allowing for easier clean-up.

By rounding up these tools and materials beforehand, you’ll optimize your workflow and effectively address any issues that arise during maintenance. Prepare to engage with the task at hand skillfully.

Disassembling the Cleaning Device Handle

First, disconnect the power source from your equipment and relieve any remaining pressure. This step ensures safety during disassembly.

Using a screwdriver, remove any screws securing the casing of the handle. Ensure you keep screws in a designated place to avoid losing them. If the screws are stuck, a penetrating oil can help loosen them.

Carefully pull apart the casing, taking note of how components fit together. If the handle is designed with clips, gently pry them open with a flathead screwdriver, avoiding excessive force which may cause damage.

Once the casing is open, locate the internal components such as the trigger mechanism and seals. Document or photograph the arrangement of these parts to aid in reassembly.

Inspect the seals and any O-rings for wear or damage; they are typically the culprits behind issues. Remove these components gently, paying attention to their orientation. If they appear compromised, replace them with matching specifications.

For better access, detach the trigger mechanism if necessary. This might involve removing additional screws or clips. Handle parts with care; a small brush can help remove dirt or debris from the components.

Store all disassembled parts in an organised manner to facilitate smooth reassembly. Following these steps methodically will prepare you for the subsequent phases of addressing faults within the assembly.

Inspecting O-rings and Seals for Damage

Begin by examining the O-rings and seals for any signs of wear or distortion. Look for cracks, tears, or any surface degradation that might compromise their integrity.

To carry out this inspection effectively:

- Remove the O-ring or seal from its housing using your fingers or a small tool to avoid damage during extraction.

- Inspect the entire circumference of the O-ring for irregularities. A good O-ring should maintain a smooth profile without any indentations or missing segments.

- For seals, pay attention to the surface contact area. Any unusual marking or deformation indicates a need for replacement.

If you identify any damage, replace the O-ring or seal promptly. Ensure you select components that fit the specifications of your model, as incorrect sizes can lead to inefficient sealing and further complications.

Cleaning and Preparing for Replacement

Prior to installation of new components, clean the seating area thoroughly. Use a soft cloth or brush to remove any debris, dust, or old lubricant. A clean surface guarantees a better seal and prolongs the lifespan of the new O-ring or seal.

Installation Tips

When installing replacements, apply a small amount of silicone grease to the O-ring or seal. This step prevents tearing during installation and enhances the sealing capability. Carefully place the component within its groove, ensuring it sits evenly without pinching or misaligning.

Replacing Faulty Components

Check the O-rings first; if they’re worn or cracked, replace them immediately to ensure a proper seal. Use the appropriate size O-rings that fit snugly in their grooves.

Swapping Out Seals

If the seals have deteriorated, it’s wise to replace them as well. Carefully remove the old seals and ensure the seating area is clean before installing new ones. Use a thin layer of silicone grease on the new seals to aid in installation and enhance longevity.

Changing the Trigger Mechanism

If the trigger is malfunctioning, dismantle it and inspect for damage or wear. Replace any broken components. Pay attention to the springs; a weak spring can hinder functionality. Ensure that the new parts are compatible with your unit.

Finally, test the assembly for leaks by running the unit on low pressure. Check all newly installed components closely; if any part continues to drip, give it another examination to confirm a proper installation. This step ensures a seamless operation and extends the life of your device.

Reassembling the Pressure Washer Nozzle

Align all components accurately and ensure no parts are missing. Begin with the body, carefully inserting the trigger mechanism. Verify that it moves freely without obstruction.

Securing the Assembly

Utilise the screws removed during disassembly to secure the main parts. Tighten each fastener in a criss-cross pattern for even pressure distribution. This prevents misalignment and ensures a solid assembly.

Final Checks

Inspect all joints and seals before attaching hoses or nozzles. Look for any visual defects, ensuring that everything appears intact and correctly fitted. Conduct a brief test run to verify performance, keeping an eye out for any irregularities.

| Part | Action |

|---|---|

| Body | Reinsert the trigger mechanism and secure. |

| Screws | Tighten in a criss-cross pattern. |

| Seals | Inspect for proper alignment and fit. |

| Test | Run a performance check after assembly. |

Testing for Leaks After Repair

After reassembly, connect the cleaning tool to a water supply and turn on the system to check for any signs of fluid escape. Observe all joints, connections, and component interfaces closely. Ensure that the pressure is within the manufacturer’s specified range before commencing the test to prevent undue stress on any parts.

Start by activating the trigger to release elements under pressure. Pay close attention to the area where the handle meets the body and where the nozzle attaches. Any signs of escaping liquid may indicate that seals or O-rings were not properly installed or may still be compromised.

If no immediate leaks are visible, run the unit for several minutes. This allows the components to warm up and expand, which can sometimes reveal hidden issues. A towel can be helpful to wipe down suspected areas prior to testing, as any new moisture will make identifying leaks easier.

For added assurance, you may apply mild soap solution to the suspected areas. Bubbles will form at points where leaks exist. If any defect is discovered, carefully disassemble again and reassess the integrity of O-rings, seals, and fitted parts.

Taking these steps will ensure your maintenance efforts were successful and that the device is functioning reliably, ready for its next challenging task ahead.

FAQ:

What are the common causes of leaks in a pressure washer gun?

Leaks in a pressure washer gun can occur for several reasons. One common cause is wear and tear on seals and O-rings, which can degrade over time and lose their effectiveness. Another potential issue could be a loose connection at the nozzle or trigger. Additionally, cracks in the gun’s body, often resulting from impacts or extreme pressure, can also lead to leaks. Regular inspection and maintenance of these components can help in identifying these problems before they become significant.

How can I fix a leaking pressure washer gun myself?

To repair a leaking pressure washer gun, first, ensure the machine is turned off and disconnected from the power source. Inspect the gun for any visible damage, such as cracks or loose fittings. If the O-rings or seals appear worn, they may need to be replaced. Removing the nozzle and checking for debris can also solve leakage issues. Some leaks can be fixed by simply tightening the fittings. For more persistent leaks, you might need to replace specific parts, which can often be done with a screwdriver or wrench. Always refer to the manufacturer’s instructions for specific guidance on your model.

Is it necessary to replace the whole pressure washer gun if it leaks?

Not necessarily. Often, you can repair a leaking pressure washer gun by replacing individual components, such as seals or O-rings. If the body of the gun is cracked or severely damaged, replacing the entire unit may be the best solution to ensure safety and performance. Before making a decision, evaluate the extent of the damage. If repairs can be made easily and economically, that might be the more sensible option. However, if repairs are too complicated or costly, considering a new gun may be wise for longer-term reliability.