To begin operating your new high-pressure cleaning device, ensure you locate the user manual first. Referencing this will provide you with specific guidelines tailored for your model, which is crucial for optimal performance.

Next, locate an appropriate outdoor water source. It’s best to utilise a garden hose equipped with a compatible connector for your machine. Ensure there are no leaks, as this can affect performance significantly. In addition, check that the water supply is adequate to meet your cleaner’s requirements.

Before connecting to power, inspect the extension cord for any signs of damage. A heavy-duty cord with the correct wattage rating will ensure safe operation. Once all connections are secure, turn on the water supply and then power up the unit. Remember to follow the start-up sequence indicated in the manual, as this will help avoid potential malfunctions.

Finally, adjust the nozzle setting according to the surface you intend to clean. Different surfaces require specific pressure levels. For instance, delicate surfaces benefit from a wider spray, while tougher materials may require a concentrated jet.

Configuration of Wilks USA Cleaning Equipment

Begin by ensuring that the device is positioned on a level surface and remains stable during usage. Verify that all components are securely assembled according to the manual’s instructions.

Connecting Water Supply

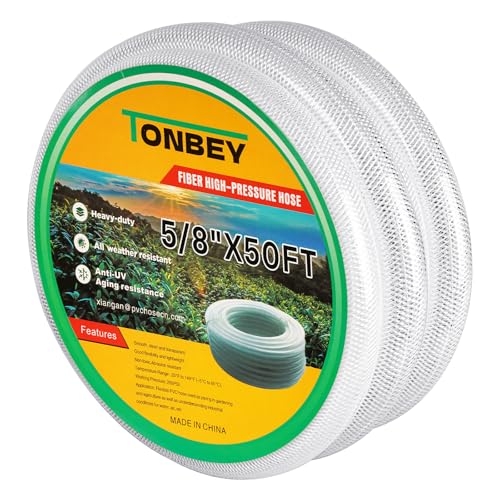

Attach a garden hose to the water inlet, making certain that it fits tightly to prevent leaks. Always check the hose for kinks or blockages. Clear water supply is essential for optimal performance, so ensure the hose is free from obstructions.

Starting the Device

- Fill the fuel tank with fresh, appropriate fuel, ensuring there are no spillages.

- Check the oil level, adding oil if necessary to maintain the recommended level.

- Engage the choke if the engine is cold.

- Pull the ignition cord firmly until the engine starts. Adjust the choke as needed once the engine is running smoothly.

Confirm all connections, then inspect the nozzle selection to suit the cleaning task at hand. Adjust settings based on the surface type for effective cleansing without damage.

Usage Tips

- Maintain a safe distance from the surface to avoid damage.

- Use sweeping motions for an even wash and reduce streaking.

- Always follow safety protocols, including wearing protective gear, especially eye protection.

Regular maintenance checks will prolong the lifespan of the equipment. After each use, flush the system to clear any residual cleaning agents or debris. Cleaning the nozzle will prevent clogs and ensure a consistent spray pattern.

Unboxing and Inspecting Your Wilks USA Pressure Washer

Upon receiving the equipment, locate a suitable area to unpack. Ensure the space is clear of obstructions, allowing easy movement. Begin by removing the outer packaging carefully, keeping an eye out for any external damage. Use a utility knife, but be cautious to avoid cutting into the product itself.

Once the box is open, take out all components methodically. This typically includes the unit itself, hose, nozzle attachments, and any additional accessories. Lay everything out to ensure nothing is missing. Refer to the manual for a complete list of included items.

Inspect the main unit for any signs of damage. Look for dents, scratches, or any irregularities that might indicate mishandling during transit. Pay special attention to the power cord and fittings, as these areas can sustain the most impact.

Next, examine the hoses. They should be free from kinks and abrasions. Check the connectors for any manufacturing defects. Make sure that all nozzles are included as per the instruction manual and that they function correctly when attached. Give them a quick test by changing the angles and checking the locking mechanism.

If you notice any discrepancies or damages, it’s crucial to contact customer support right away to address these issues. Keep all packaging materials until you’re certain that everything is in good working order. This will facilitate any returns or exchanges if necessary.

With everything inspected, you’re now ready to assemble the components. Double-check that you have the correct tools on hand, as specified in the manual. This ensures a smooth assembly process, preventing unnecessary stress.

A proper unboxing and inspection process lays the groundwork for effective use of your new cleaning equipment. Ensuring everything is in pristine condition guarantees optimal performance for your cleaning tasks ahead.

Identifying Components and Accessories Included

Upon unboxing, it’s critical to identify all parts included in the package to ensure a smooth setup and operation. Begin by locating the main unit, which is the heart of the equipment. Alongside it, there should be a variety of components essential for functionality.

Look for the following key items: a high-pressure hose, typically around 8-10 metres long, allowing flexibility during use. The spray gun should also be present, which is vital for directing the water flow. Attached to the gun, or included separately, are different nozzles that adjust the spray pattern. These usually range from a narrow jet for tough stains to a fan spray for wider coverage.

Additionally, you should find extensions or surface cleaning attachments, if applicable, which provide specialised cleaning capabilities. A bottle of detergent or a detergent tank might be included, meant for enhancing cleaning power when necessary. Don’t overlook the quick-connect fittings that simplify the process of swapping attachments.

Check for caster wheels or a handle, which facilitate mobility, along with a power cord appropriate for your region’s voltage standards. Ensure you have the necessary documentation, including the user manual, for troubleshooting and maintenance tips. Having all these components ready and identified will enable a seamless initiation into using your newly acquired cleaning device.

Preparing Your Cleaner for Assembly

Ensure you have a clear, flat workspace for assembly. Gather all necessary components and tools before starting. A clean surface helps in preventing loss of small parts and allows for efficient assembly.

Inspect all items carefully for damage. Check hoses, nozzles, and attachments for any signs of wear. Having everything intact guarantees a smoother assembly process.

Familiarising with the Manual

Read through the instruction manual thoroughly. This provides essential insights into the steps involved in assembling the unit. Pay close attention to diagrams and assembly sequences to avoid errors.

Organising Components

Arrange the components by type and function. Group hoses together, nozzles in another area, and the main unit separately. This organisation streamlines the assembly process and ensures that you have all parts accessible as needed.

Keep essential tools, such as screwdrivers and wrenches, at hand for quick access. Avoid unnecessary delays by having everything ready before commencing assembly.

Connecting the Water Supply to the Pressure Washer

Begin by locating the water inlet on the machine. Ensure the unit is powered off and disconnected from any electrical sources to prevent accidents.

Utilise a standard garden hose suitable for water supply. Ensure there is no damage to the hose, as leaks can hinder operational efficiency. Attach one end of the hose to the water source and the other to the inlet of the cleaner. Ensure the connection is secure to avoid any leaks.

Check that the water supply is clean and free of debris. Contaminants can cause blockages and damage internal components. If necessary, use a filter at the hose connection point to safeguard against impurities.

Water Supply Pressure Requirements

The ideal water pressure for optimum performance typically ranges from 20 to 100 PSI. Measure the pressure using a gauge if available. Insufficient pressure may prevent the equipment from functioning properly.

Quick Connection Tips

| Step | Action |

|---|---|

| 1 | Attach hose to water source securely. |

| 2 | Connect other end to the unit’s inlet. |

| 3 | Check for leaks at both connection points. |

| 4 | Open the water supply to allow flow. |

| 5 | Ensure steady pressure and flow before powering on. |

Once the connections are complete, do a final inspection for leaks and tightening before initiating operation. This not only enhances safety but also ensures effective performance during use.

Installing the High-Pressure Hose and Nozzle

Begin by locating the high-pressure hose. First, ensure that the connections are clean and free from debris. Align the hose’s connector with the opening on the unit and twist it clockwise until secure. Take care to avoid cross-threading, which can lead to leaks and inefficiencies.

Attaching the Nozzle

Select the appropriate nozzle for your cleaning task, and slide it onto the end of the high-pressure hose until you hear it click into place. This indicates that it is securely attached. If your model comes with multiple nozzles, refer to the user manual for guidance on which one is best suited for different surfaces.

Testing for Leaks

After connections are made, turn on the water supply and press the trigger on the lance to release air from the system. Keep an eye on all attachment points for any signs of leakage. If you detect any water escaping, disconnect and reattach the hose or nozzle as needed, ensuring that all components are tightly secured.

Setting Up the Power Source for Operation

Connect your cleaning device to a suitable electrical outlet. Ensure that the voltage matches the requirements specified in the user manual, usually 120V or 240V, depending on your region.

Using the Correct Power Cord

Utilise a heavy-duty extension cord if the outlet is far from your workspace. The cord must be rated for outdoor use and match or exceed the amperage specified in the manual. A minimum gauge of 12 AWG is recommended for longer distances. Avoid daisy-chaining multiple cords as this can lead to overheating and potential hazards.

Safety Precautions

Inspect the power cord for any damage prior to use. If frayed or exposed, replace it immediately. Keep the cord away from water to prevent electric shock. Ensure your hands are dry when plugging or unplugging the device.

Make sure the circuit can handle the load of your equipment. Dedicated circuits are preferable to avoid tripping breakers. If using outdoor outlets, ensure they are GFCI (Ground Fault Circuit Interrupter) protected to enhance safety.

Testing the Pressure Washer for Initial Functionality

Begin operation by plugging the machine into a suitable electrical outlet. Ensure that the power cord is undamaged and securely connected to the source. Check for any visible issues such as frayed wiring or loose connections.

Next, turn on the water supply. It’s vital to eliminate air from the system; do this by pressing the trigger on the spray gun until a steady stream of water flows from the nozzle. This step prevents damage during startup due to air pockets.

After achieving a steady flow, activate the motor. Look for a smooth start without unusual noise or vibrations. If the motor struggles or fails to start, double-check connections and supply lines.

Once the unit is running, test the spray function. Switch the nozzle settings (if applicable) to confirm multiple spray patterns are working. Pay attention to:

- Pressure consistency: Ensure there is no fluctuation in the water pressure when engaged.

- Leakage: Examine all connections for any signs of water leakage during operation.

- Adjustability: Check that you can easily switch between different spray angles and pressures.

Conduct a brief cleaning test on a small area of dirt or grime to evaluate performance. Observe how it tackles various surfaces and how the nozzles affect the cleaning power.

After testing, switch off and disconnect the unit. Allow it to cool down, then perform a thorough inspection to identify any issues that may need addressing before the next use.

Maintaining Your Wilks USA Pressure Washer for Longevity

Regular inspection of all components is fundamental. After each use, examine the high-pressure hose for any signs of wear or damage. Inspect the nozzle for clogs and clear debris if necessary.

Flushing the system with clean water is crucial to prevent the buildup of contaminants. After each operation, run clean water through the unit for a few minutes to cleanse the internal components.

Utilising the correct detergent is essential. Only use cleaners recommended by the manufacturer to avoid damaging seals and gaskets. Always follow dilution guidelines for optimal cleaning without harming the equipment.

Periodic lubrication of moving parts will prolong lifespan. Refer to the manual for specific lubrication points and recommended lubricants.

Storing the device properly will prevent damage during idle periods. Keep it in a dry, protected location to avoid moisture accumulation, which can lead to rust and corrosion.

Lastly, reviewing the user manual for routine maintenance intervals is vital. Following these recommendations will ensure reliability and performance over the years.