Fill the fuel tank with the appropriate gasoline, ensuring you use a clean funnel to avoid contamination. I recommend a blend that includes a fuel stabiliser to enhance performance and prevent degradation during idle periods.

Next, inspect the oil levels. Checking the crankcase ensures the engine operates smoothly. Use a suitable oil type as specified in the owner’s manual. If the oil appears dirty or has not been changed in a while, it’s wise to replace it before proceeding.

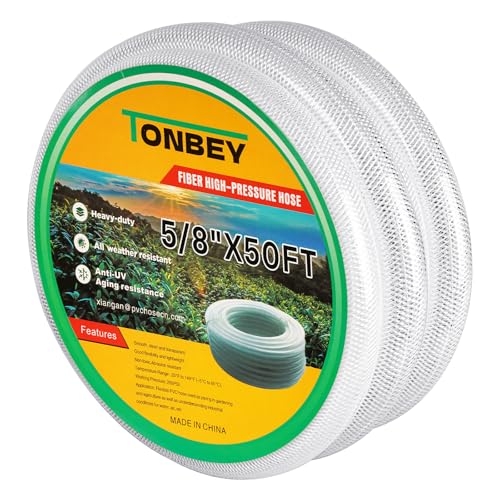

Attach the high-pressure hose securely to the machine and the spray gun. Make sure all connections are tight to prevent leaks. When you’re ready, connect the water supply hose, ensuring that the water source is adequate for the device’s specifications.

Priming the system is crucial. Turn on the water supply and allow the pump to fill up, then squeeze the trigger on the gun until a steady stream of water flows. This expels air trapped in the system, making the next steps easier.

Once prepared, turn the ignition switch to the ‘On’ position. Pull the starter cord firmly until the engine roars to life. If it doesn’t start immediately, give it another quick pull. If you’re experiencing difficulty, double-check the fuel and oil levels once more.

With the engine running, adjust the throttle as necessary for optimal power. You’re now equipped to tackle any cleaning task effectively.

Procedure for Engaging Your Equipment

Check the fuel level in the tank; ensure it’s filled with the correct type. For best results, use clean, fresh fuel to avoid starting difficulties.

Engage the choke by toggling the appropriate lever to the ‘on’ position. This adjustment facilitates fuel intake during ignition.

Ensure the unit is in a stable position. Grip the handle firmly, and prepare to pull the recoil starter cord. This action provides the necessary force to initiate combustion.

Once you’ve located the throttle control, set it to the proper position–typically halfway. This helps in maintaining a steady engine speed during operation.

With a secure hold on the unit, pull the starter cord briskly. If the engine doesn’t catch after a couple of attempts, revisit your fuel and choke settings. Adjustments might be necessary for optimal performance.

Upon successful ignition, allow the engine to idle for a short period, ensuring it runs smoothly without any unusual sounds or vibrations. Once satisfied, proceed with your cleaning tasks.

After usage, turn off the unit by toggling the switch to the ‘off’ position and disengage the choke. This will reset the machine for its next operation.

Understanding the Yanmar Pressure Washer Components

The vital parts of the cleaning unit include the motor, pump, and nozzle assembly, which work together to deliver high-performance cleaning. Familiarity with these elements enhances maintenance and operational efficiency.

| Component | Function | Maintenance Tips |

|---|---|---|

| Motor | Drives the pump to create pressure. | Regularly check the motor for debris and ensure connections are secure. |

| Pump | Generates and regulates water pressure. | Inspect for leaks and use the correct oil type; replace seals as needed. |

| Nozzle Assembly | Adjusts spray pattern and pressure level. | Clean nozzles regularly to prevent clogs; replace if worn. |

| Hose | Transfers water from the unit to the spray nozzle. | Avoid kinks and check for any wear; store properly to prevent damage. |

Understanding these components aids in diagnosing issues and troubleshooting effectively. Each part’s condition directly affects the overall operation and longevity of the equipment.

Preparing Your Workspace for Safe Operation

Choose a clean, dry surface to set up your equipment. This minimises the risk of slips and falls. Ensure the area is well-ventilated to prevent gas buildup from the engine.

Clear Potential Hazards

- Remove any debris, such as leaves or branches, from the vicinity.

- Ensure that electrical cords or hoses do not create trip hazards.

- Keep pets and children at a safe distance to prevent accidents.

Gather Necessary Supplies

Before you begin, assemble the following items:

- Protective gear: goggles, gloves, and non-slip footwear.

- Extension cords rated for outdoor use if necessary.

- Water supply source connected and ready to go.

Inspect your setup to ensure that all connections are secure. Keep your workspace organised to allow for smooth operation. Lastly, have a first-aid kit on hand for emergencies.

Checking Fuel and Oil Levels Before Starting

Before engaging the cleaning unit, it’s vital to confirm fuel and oil levels. Open the fuel cap and visually inspect the tank. Ensure there’s enough fuel to avoid interruptions during use, as the generator relies on an adequate supply for optimal performance. If the level is low, refill with fresh fuel, avoiding mix types that could harm the engine.

Next, check the oil reservoir. Locate the dipstick, remove it, and wipe it clean. Reinsert it without screwing it in, then pull it out again to gauge the oil level. It should reach the full mark. If it’s below, add the recommended oil type specified in the owner’s manual. Running the unit with insufficient oil can lead to significant damage.

After confirming both levels, securely fasten the fuel and oil caps. This prevents spillage when the machine is in operation, ensuring a safe and clean working environment. These preliminary checks enhance longevity and efficiency, ultimately saving time and resources.

Connecting the Water Supply to the Cleaning Unit

Attach the garden hose to the water inlet of the cleaning unit, ensuring a tight fit to prevent leaks. Use a rubber washer inside the connection to enhance the seal if necessary. Make sure the hose is of adequate length to reach the water source without stretching.

Open the water supply valve fully before turning on the machine. A consistent water flow is crucial for optimal operation. If the unit has a filter, inspect it regularly for debris that may block water flow, especially if using untreated water sources.

Before connecting, check for any kinks or damages in the hose that might impede water passage. If there are issues, replace the hose. Using a hose reel can help keep the supply line untangled and organised.

Once connected, ensure there are no leaks at the fittings. If leaks are identified, tighten connections or replace faulty components. Always keep the source water clean–avoid using water from places where contaminants may affect performance.

After establishing the connection, proceed with any additional programming or adjustments required for your specific cleaning functions. This foundational step directly influences the machine’s effectiveness during use.

Inspecting the Hose and Nozzle for Proper Functionality

Examine the hose for any signs of wear or damage. Look for cracks, bulges, or leaks that could affect performance. Ensure the connections at both ends are secure and tightly fitted. A compromised hose can lead to loss of pressure and hinder cleaning efficiency.

Testing the Nozzle

Verify that the nozzle is free from debris and blockages. Use a small, stiff brush or a cloth to clean it thoroughly. Check the spray pattern by connecting the nozzle and running water through it. If the stream is uneven or the pattern is inconsistent, consider replacing the nozzle for optimal results.

Ensuring Proper Connection

Make sure the hose and nozzle are properly connected. Loose or misaligned connections can result in water leaks, impacting the performance significantly. Tighten all fittings carefully without overtightening, which can damage the threads or cause leaks.

Engine Ignition: Step-by-Step Guide

Follow these concise procedures to energize the unit effectively:

-

Check the On/Off Switch: Ensure the ignition switch is in the “On” position before proceeding.

-

Engage the Choke: If the engine is cold, pull the choke lever to the “Closed” position. This aids in the fuel-air mixture.

-

Position the Throttle: Set the throttle to the “Start” position; this supplies sufficient fuel for ignition.

-

Pull the Starter Rope: Grasp the starter handle firmly and pull it briskly. Repeat if necessary until the engine fires.

-

Adjust the Choke: When the engine starts, gradually move the choke to the “Open” position after a few moments.

-

Warm Up: Allow the engine to idle for a short duration, giving it time to reach optimal operating temperature.

Common Issues and Troubleshooting

If the engine fails to ignite:

- Verify that there is fuel in the tank.

- Check fuel lines for blockages or leaks.

- Ensure the air filter is clear of debris.

- Inspect the spark plug for wear or fouling.

Make these assessments before repeated attempts, ensuring a smooth and effective ignition experience.

Adjusting Pressure Settings for Different Cleaning Tasks

For optimal results, adjusting the force of the water stream is key based on the cleaning task at hand. For delicate surfaces such as cars or painted elements, reduce the intensity to around 1200-1500 psi. This prevents damage while ensuring adequate cleaning.

In contrast, for tougher jobs like removing grime from concrete or decks, increase the pressure to approximately 2500-3000 psi. This higher force effectively removes stubborn dirt without requiring excessive scrubbing.

Utilising the adjustable nozzle is crucial. A wide fan spray is perfect for large areas and gentle cleaning, whereas a narrow jet is suited for specific spots and tough stains. Always test the pressure on a small, inconspicuous area first to confirm suitability.

Remember, consistency is important. Maintain a steady distance of around 2-3 feet from the surface to ensure even cleaning without causing surface damage. Adjusting both the pressure and nozzle type can significantly enhance performance and efficiency, making every task straightforward.

The right settings transform any cleaning challenge into a manageable activity, allowing for quicker completion while achieving excellent results. Evaluating the surface condition beforehand helps in deciding the appropriate adjustments.

Maintaining Your Pressure Cleaner After Use

After using your cleaning machine, I recommend promptly shutting off the engine and disconnecting the water supply. This immediate action prevents potential leaks and ensures safety while handling the equipment.

Next, it’s crucial to empty the water from the system. Disconnect the hose and spray gun, then activate the trigger to expel any remaining water. This step reduces the risk of freezing or buildup in the lines, prolonging the life of your device.

Cleaning Components

I always advise carefully inspecting and cleaning the nozzle and hose. Any debris or residue can impair functionality, so a soft brush or cloth works well to wipe them down. For stubborn blockages, soaking the nozzle in warm, soapy water can help.

Storing the Equipment

Ensure the machine is stored in a dry, sheltered location, away from extreme temperatures. If you expect cold weather, consider using a pump protector to safeguard the internal components from frost damage. Lastly, check the fuel and oil levels before storage, topping up as necessary to avoid issues when you return to use the equipment.