Begin with ensuring the machine is completely drained of water. This step is critical, as any residual fluid can lead to damage when the temperature drops. Remove the drain plug and allow any remaining liquid to exit. It’s advisable to keep the device tilted to ensure thorough drainage.

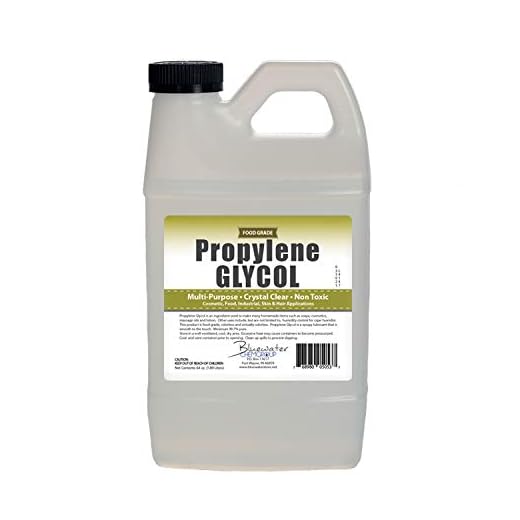

After confirming the system is empty, gently add the antifreeze solution into the designated inlet. Follow the manufacturer’s guidelines for the correct type and quantity, as incorrect usage could compromise the internal components. Use a funnel for precision and to avoid spills.

Next, activate the motor for a brief period – typically around 30 seconds. This action ensures the antifreeze cycles through the system, reaching all necessary parts. Be attentive to any unusual sounds during this process; if something seems off, it may warrant further investigation.

Complete the process by removing any excess fluid and sealing the inlet. Store the equipment in a frost-free environment to protect it from extreme cold. Regular maintenance, including this antifreeze application, can significantly extend the lifespan of your cleaning device.

Application of Freeze Prevention Liquid in Cleaning Machines

First, ensure the equipment is turned off and unplugged. Remove any existing liquid from the tank using a siphon or by running the machine briefly until it empties, avoiding potential dilution issues.

Next, dilute the freeze prevention product with water according to the manufacturer’s guidelines. Typically, a mixture of 50% liquid and 50% water is recommended for optimal protection.

Carefully pour the prepared solution into the tank. Engage the machine to circulate the mixture through the system, allowing it to reach all internal components. It’s advisable to run the unit for a few minutes to guarantee complete distribution.

After circulation, disconnect the hose and nozzle from the machine. This prevents any unwanted residue from accumulating. Store the equipment in a frost-free environment to enhance longevity.

Before starting the device for spring cleaning, flush the system with water to ensure any residual liquid is removed. This step prepares the machine for regular use without compromising performance.

Choosing the Right Anti-Freeze Product

After years of hands-on experience, I recommend selecting products specifically designed for cleaning machines. Look for formulations that advertise compatibility with various materials found in your equipment, such as rubber and plastic seals, as improper chemicals can lead to damage.

Focus on non-toxic options, especially if you will operate the device around pets or plants. Eco-friendly formulas often feature biodegradable components, reducing environmental impact.

| Brand | Type | Compatibility | Eco-Friendly |

|---|---|---|---|

| Brand A | Concentrated | All types of devices | Yes |

| Brand B | Ready-to-use | Electric models only | No |

| Brand C | Non-toxic | Gas models | Yes |

Evaluating the freeze protection level is vital, especially in colder climates. Products often indicate the lowest temperature they protect against, measured in degrees Fahrenheit or Celsius. Ensure the selected item meets your area’s climate demands.

Lastly, consider the ease of application. Some items come in user-friendly containers or with simple mixing instructions, which can save time and effort during the winterisation process.

Preparing Your Cleaning Equipment for Anti-Freeze Application

Begin by disconnecting the water supply and ensuring that the device is powered off. This prevents accidental activation while you’re preparing for the application. Following this, remove any accessories, such as nozzles and hoses, as these components may impede the flow of the fluid.

Drain residual water from the system to prevent any freezing damage. To do this, tilt the unit to allow any remaining moisture to escape from the pump and hoses. Ensure that the water outlet is directed towards a suitable drainage area.

Next, inspect and clean the filters and inlet screens. Debris can hinder the antifreeze solution’s effectiveness. Rinse them thoroughly and replace them if they’re worn out or damaged.

Once the system is dry, assemble the siphoning kit, if available, or have a funnel ready to pour the solution into the designated area. Be mindful of using a funnel that fits snugly to avoid spills.

Finally, double-check the manufacturer’s guidelines for compatibility and procedures, as different models may have specific requirements. A careful review guarantees efficacy and safeguards the equipment’s integrity.

Steps to Properly Add Anti-Freeze to the System

Ensure the machine is turned off and completely cool before proceeding.

Begin by disconnecting the water supply hose. This prevents any contamination while filling the reservoir. Removing the nozzle or wand is also advisable to facilitate the process.

1. Fill the Solution Container

Pour the appropriate amount of the non-toxic liquid into the container designated for the cleaning solution. Refer to the product instructions for the specific volume needed based on your unit’s size.

2. Activate the System

Once the reservoir is filled, reconnect the hose to the solution inlet. Start the machine and immediately allow it to run for a few minutes. This action circulates the liquid throughout the internal components, thereby providing complete protection.

After five minutes, switch off the equipment and remove the hose again to eliminate any excess liquid. Store the machine in a dry location to prevent moisture build-up.

Draining the Water

Before applying any freeze protection solution, ensure that all residual water is completely removed from the system. Here’s a straightforward process to achieve this:

- Disconnect any hoses and accessories from the unit.

- Position the unit in an upright position. This allows gravity to assist in water removal.

- Start the engine and let it run for a minute or two. This expels any remaining water from the pump and internal components.

- Shut down the engine and disconnect the high-pressure hose from the machine. This should release any trapped moisture.

- Tip the unit slightly forwards and backwards to dislodge any stubborn water remaining in the pump or housing.

Additional Steps

For extra assurance, consider the following:

- Use a wet/dry vacuum to siphon out moisture from the inlet and outlet fittings.

- Leave the unit in a warm, dry location for several hours to ensure complete evaporation.

- Inspect the detergent tank, if applicable, and drain any liquid contents to prevent freezing.

Taking these actions accurately prepares the equipment for the application of freeze protection, ensuring optimal performance and longevity.

Maintaining Your Equipment After Fluid Application

After applying the appropriate protective fluid, inspecting and maintaining the machine is crucial for optimal performance. Start by thoroughly cleaning the exterior components, ensuring no residues remain that could lead to corrosion or damage.

Check the Components

Inspect the hoses, nozzle, and pump for any signs of wear or damage. Look for cracks, leaks, or any other issues that could affect performance. If necessary, replace damaged parts immediately to prevent future complications.

Verify that the filters are clean and unobstructed. Clogged filters can negatively impact the overall function, so regular cleaning or replacement is advisable.

Storage Recommendations

Store the unit in a dry, sheltered area free from extreme temperatures. If possible, keep it indoors where conditions remain stable. If indoor storage isn’t an option, consider using a cover to protect against environmental factors.

Before storing, run the equipment briefly to clear out any residual fluids or moisture left in the system. This step is essential to avoid potential freezing issues or damage during colder months.

Conduct a seasonal check before re-use to ensure that everything remains in sound condition. After a period of inactivity, a thorough inspection can prevent operational problems that may arise from prolonged storage.

Proper care and timely maintenance lead to longevity and enhanced efficiency in your cleaning tools, allowing for consistent performance when resuming jobs.

Identifying Signs of Improper Anti-Freeze Application

Look out for these indicators to ensure correct application of coolant in your equipment:

Common Symptoms

| Sign | Description |

|---|---|

| Overheating | If the motor becomes excessively hot during operation, it could suggest inadequate protection against freezing. |

| Corrosion | Rust or scale buildup in components indicates poor fluid quality or improper mixture ratios. |

| Fluid Leaks | Visible leaks around seals and fittings suggest that the drainage or flushing was not thorough. |

| Unusual Noises | Strange sounds from the pump might signal damage caused by ice expansion from insufficient coolant. |

Examining Equipment Performance

Regularly monitoring performance can reveal clues about the presence of coolant. A noticeable drop in pressure or flow rate, along with erratic performance, can hint at potential issues caused by improper antifreeze handling.

Pay attention to how quickly your machine starts up after cold weather. A sluggish or difficult start can indicate the need for immediate inspection of your flushing process.

Storing Your Equipment During Winter Months

Ensure thorough cleaning of your device prior to storage to prevent residue accumulation. Detach the nozzle, wand, and any accessories, and store them separately in a dry location.

Drain all water from the system. Open the water inlet and let any remaining fluid flow out. This step is crucial to prevent freezing damage.

- Verify that no water is left in the pump or hoses.

- Run the motor briefly to expel any trapped moisture.

Select a dry, sheltered area for storage. If possible, place the apparatus indoors to shield it from extreme cold. An unheated garage can work, but sheltered locations are ideal.

Cover your machine with a protective cloth or a tarpaulin to keep dust and debris at bay. This precaution helps preserve the exterior and internal components.

Consider elevating the unit off the ground to avoid contact with cold surfaces, which could lead to frost accumulation. Wooden pallets or shelves are practical options.

- Provide ventilation to prevent mold and mildew during storage.

- Check periodically for any signs of wear or damage and address them promptly.

Before you resume use in the spring, conduct a detailed inspection. Ensure all components are intact and there are no signs of freeze damage or corrosion.