Monitoring water levels is crucial for maintaining the optimal performance of your appliance. A pressure regulator plays a vital role in accurately detecting the water level within the drum, ensuring that the unit operates efficiently and effectively during cycles.

When the water enters, this component promptly identifies the changes in pressure and communicates with the control system to manage water intake. If the pressure is too low, it signals the valve to allow more water, ensuring that the laundry is properly soaked. Conversely, if the predetermined level is reached, it halts the flow, preventing overflow and potential damage.

This device can also prevent unnecessary wear on the appliance’s motor by ensuring that the water levels remain consistent. In situations where it malfunctions, users may experience issues such as flooding or insufficient washing, signalling the need for immediate attention. Regular maintenance checks for this part can save on repair costs and extend the lifespan of your equipment.

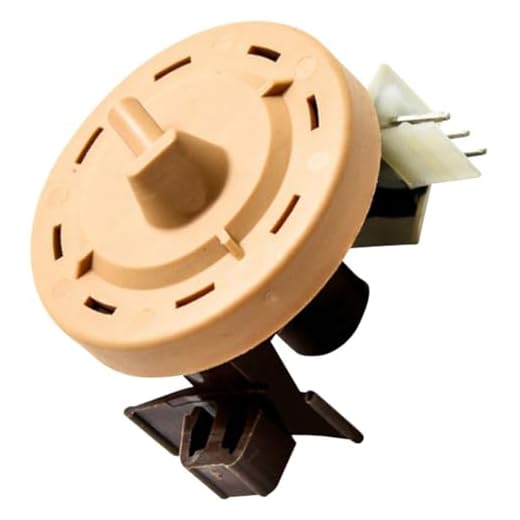

Understanding the role of the pressure switch in a washing machine

The component in question regulates the water level within the drum, ensuring safety and performance of the appliance. Its reliable functionality is key to preventing overfilling. Here’s a detailed breakdown of its operation:

- Water Level Detection: The mechanism uses air pressure to determine the amount of water in the drum, adjusting cycles accordingly.

- Cycle Control: As the water fills, changes in pressure signal the control board to initiate or halt the water inflow, which helps maintain the correct levels.

- Safety Functions: If malfunctions occur, this element plays a critical role in preventing leaks by shutting down the fill process, thus safeguarding the internal components.

Regular checks are advisable to ensure that it’s functioning properly; a malfunctioning part can lead to issues such as flooding, poor cleaning results, and inefficient water usage. Addressing these concerns promptly can extend the lifespan of your appliance.

In case of failure, identifying signs–such as unusual sounds or error codes–can be beneficial for troubleshooting. Replacement is often straightforward, but ensure compatibility with your specific model for optimal results.

How the pressure sensor detects water levels

The operation of the water level detection mechanism is based on changes in air pressure created by the water column within the drum. Here’s how it functions:

- The sensor is connected to a thin tube leading to the drum. As water fills the drum, the water height increases, which in turn elevates the water column pressure.

- This pressure change is transmitted through the tube to the sensor, which has a diaphragm that responds to variations in pressure.

- When the diaphragm is pressed by the water pressure, it activates contacts within the sensor, sending a signal to the control module of the machine.

- The control module interprets this signal, determining whether the drum has reached the desired level of water and adjusts the filling process accordingly.

This mechanism provides precise control over the wash cycle, enabling efficient water usage and preventing overflow. In models equipped with advanced features, the sensor may adjust dynamically during various stages of the washing process, allowing for better performance based on load size and fabric type.

Regular maintenance of the tube connecting the sensor is crucial to ensure accurate readings. A blockage could lead to incorrect water levels, affecting washing efficiency.

Common issues related to pressure sensors in washers

In my experience, several common faults can occur with water level sensors in laundry machines. These often lead to performance issues that can frustrate users.

Incorrect water levels

One frequent problem is inaccurate water levels. This may happen due to clogs or blockages in the tubing that connects to the sensor. Regular inspection and cleaning of these tubes can help. If the sensor itself is damaged or malfunctioning, replacing it is essential to restore proper functionality.

Failure to fill or drain

Another issue arises when the machine fails to fill or drain properly. If the sensor does not detect water, it may be a sign of electrical faults or a bad connection. Checking the wiring for damage or corrosion can often resolve this. Additionally, ensure that the machine’s control board is functioning correctly, as this can directly impact sensor operation.

Unexpected interruptions in cycles, where the cycle halts mid-way, can also point to issues in the sensor. Regular maintenance checks can pre-empt such failures and prolong the life of the appliance.

Symptoms of a Faulty Water Level Sensor in a Washing Machine

.jpg)

If you notice inconsistent water levels during cycles, it’s a sign that the water level detector may be malfunctioning. When the appliance fails to fill adequately or overfills, it directly impacts its performance.

Experiencing unusual error messages on the control panel can indicate problems with the water level mechanism. These alerts serve as warnings related to the sensor’s accuracy or its connection with the main control board.

Unusual noises, such as clicking or buzzing, during the filling process may suggest that the device is struggling to detect the correct water levels. This could signal an underlying issue with the sensor or its attached hose.

Additionally, frequent interruptions during the wash cycle can occur due to erratic communication between the control module and the water level component. When cycles stop prematurely, it’s often due to incorrect readings from the sensor.

Leaking water around the unit is another critical symptom to address. This could involve a cracked tube linked to the sensor or a failed component affecting water regulation.

If these signs appear, evaluating the water level sensing component is essential to maintain optimal functionality in the laundry appliance. Regular maintenance and timely diagnostics can prevent larger issues down the line.

Steps to Test the Functionality of the Pressure Control Device

Begin the assessment by unplugging the appliance to ensure safety during testing. Removing any water from the drum can prevent accidental flooding while you work.

Visual Inspection

Inspect the component for any visible signs of damage, such as cracks or wear. Check the tubing connected to it for blockages or leaks that can impair its operation. A clean, unobstructed path is crucial.

Electrical Testing

Using a multimeter, set it to measure resistance. Disconnect the wires attached to the element, then place the probes on the terminals. A reading within the manufacturer’s specifications indicates proper functionality. If there’s no continuity, replacement is necessary.

After checking, reattach the wires and reconnect the device. Run a cycle without laundry to observe if it successfully detects water levels and signals when to fill and stop filling. Any inconsistencies here may point to further issues needing attention.

How to replace a defective pressure switch

Start by disconnecting the appliance from the power source to ensure safety during the replacement process. Once unplugged, locate the component, typically found near the water reservoir or the control panel.

Carefully remove any screws or clips securing the component in place. Take note of the wiring connections. It’s helpful to photograph the setup for reference when attaching the new device.

Disconnect the wires, gently pulling them off their terminals. If you encounter resistance, use a flathead screwdriver to pry gently without damaging them. Ensure that you identify which wire connects to which terminal for correct reassembly.

Install the new component by following the reverse order of removal. Attach the wires to their respective terminals, making sure they are secure. Reattach any screws or clips to hold the new part firmly in place.

After assembly, reconnect the power and test the unit to verify proper operation. Check for leaks or unusual sounds, indicating correct installation.

If the issue persists, double-check the connections and consider consulting an expert for further assistance.

Preventive Maintenance Tips for Pressure Monitoring Devices

Regularly inspect the hose connected to the device for kinks or wear. Any physical damage can lead to inaccurate readings.

Keep connections clean and free from debris. Dirt and grime can impede the functionality of internal components, leading to miscalculations.

Periodically test the device’s settings against known measurement standards to ensure accuracy. This check will help identify potential discrepancies early.

Ensure that the surrounding area remains dry. Moisture can cause corrosion and malfunction over time.

Check for loose electrical connections. Ensure all wiring is securely attached and insulated to prevent short circuits that could impair operation.

Consider using surge protectors to shield the device from power spikes that can cause damage.

If applicable, refer to the manufacturer’s guidelines for specific maintenance schedules and recommendations tailored to your model.

Maintain proper water levels in the storage tank to prevent overextension or underperformance during cycles.

Record maintenance activities and issues encountered. Keeping a log will help in tracking performance over time and may indicate patterns that need addressing.

Lastly, engage a qualified technician for any complex issues or replacements to ensure optimal functionality. Their expertise can save you from future complications.

Comparing pressure switches across different washing machine models

In my extensive experience in the cleaning equipment industry, I have observed significant variations in mechanisms employed by various brands. Pressure regulation devices exhibit diverse characteristics, tailored to meet specific operational demands and user preferences.

Key Features

.jpg)

Different manufacturers integrate unique features into their models. Some systems incorporate advanced algorithms for accurate water level detection, while others rely on mechanical components. For instance, Bosch models tend to utilise advanced sensors for precise level measurements, enhancing overall reliability. Conversely, older models from brands like Whirlpool often use more traditional methods, which may lack the sophistication but provide robust performance.

Performance Differences

Performance can also vary widely. Certain units, such as those from LG, have optimised their devices for rapid response times, thus shortening cycle periods. In comparison, more economical options may employ slower response mechanisms, potentially impacting wash quality. The choice between responsiveness and price often leads consumers to prefer higher-end models for better efficiency.

| Brand | Type | Response Time | Key Feature |

|---|---|---|---|

| Bosch | Electronic | Fast | Precision Sensors |

| LG | Electromechanical | Very Fast | Rapid Level Detection |

| Whirlpool | Mechanical | Moderate | Reliable Snap Action |

| Samsung | Electronic | Fast | Smart Control |

Understanding these differences assists in recognising the right choice for specific needs. Buyers can make informed decisions based on their washing habits, frequency of use, and budget considerations. It’s crucial to weigh the cost against long-term benefits, especially when performance is at stake.