For optimal results, ensure compatibility with quick connect adapters commonly utilised in high-performance cleaning units. These connectors facilitate seamless transitions between various nozzles and hoses, streamlining the cleaning process.

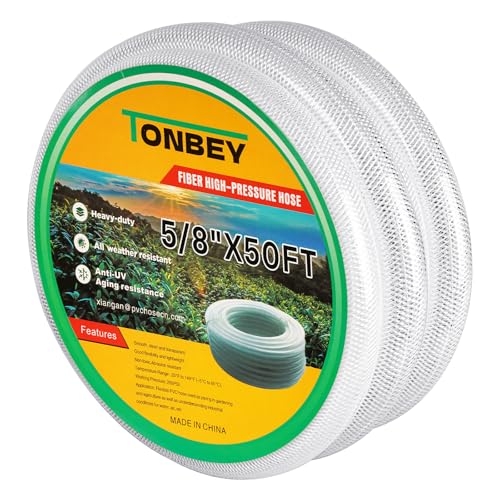

High-pressure hoses are vital; a standard diameter of 1/4 inch is frequently found in many models, providing a balance between flexibility and durability. Select hoses constructed from reinforced materials to avoid wear and potential leaks during use.

Nozzles vary in functionality, and a range from 0° to 40° angles will cater to different tasks, from intense surface blasting to mild washing. Invest in a model that includes multiple nozzles to handle various surfaces and dirt levels effectively.

Additionally, consider purchasing foam cannon attachments that enhance detergent application. Compatibility with standard outlets is essential for effective foam distribution, helping to lift tough grime before the water pressure removes it.

Finally, always check compatibility with any extension wands available in the marketplace. A longer reach allows for cleaning hard-to-access areas with ease, making your maintenance tasks smoother and more thorough.

Overview of Connectors for Workzone Equipment

For optimal performance with your equipment, it’s crucial to choose the right connectors. The system typically accommodates a variety of quick-connect fittings, which facilitate easy attachment and detachment of hoses and nozzles. I recommend using commonly available types that match the pressure ratings required by your specific model.

Types of Connectors

The common types include M22 screw connectors, which provide a reliable and secure connection for hoses. It’s beneficial to verify that your hose is compatible, as some models might use different standards.

Nozzle Compatibility

For the nozzles, you’ll primarily encounter quick-release versions that allow for rapid changes between different spray patterns. Ensure that the nozzle you select matches the inlet size of your cleaning tool for seamless operation.

Understanding Washer Connection Types

To ensure optimal performance, select the right type of connector for your equipment. Typically, there are three primary categories of connectors: quick-connect, threaded, and bayonet. Each serves distinct needs based on usage and attachment speed.

Quick-Connect Adapters

These are favoured for their ease of use, allowing rapid tool changes without requiring additional tools. They’re particularly useful for those who frequently switch between different spray nozzles or accessories. When choosing a quick-connect, be mindful of the compatibility with your current setup to avoid leaks or reduced efficiency.

Threaded Attachments

.jpg)

Threaded designs offer a secure connection, making them ideal for heavy-duty tasks. They require a bit more time to attach and detach but provide a reliable seal. Ensure that the thread size matches perfectly to prevent any mishaps during operation.

Common Nozzle Types for Workzone Pressure Washers

Choosing the right nozzle can significantly enhance cleaning performance. The following are commonly used types suited for these machines:

- Fixed Spray Nozzle: Provides a constant spray pattern, ideal for tasks like rinsing off vehicles or cleaning outdoor furniture.

- Adjustable Nozzle: Offers a simple twist mechanism to switch between multiple spray patterns, from a narrow jet to a wide fan, enabling versatile use based on the task at hand.

- Turbo Nozzle: Combines the power of a rotating jet with a concentrated spray, making it excellent for removing tough stains, grime, and dirt from hard surfaces.

- Surface Cleaner Nozzle: Specially designed for cleaning large flat areas, this type helps maintain consistent coverage, making it efficient for driveways and patios.

It’s crucial to select the appropriate nozzle based on the surface type and cleaning requirement to maximise effectiveness and avoid damage.

For example, using a turbo nozzle on a delicate surface may cause harm, while a wide spray is insufficient for tough stains. Understanding each nozzle’s application ensures optimal results.

Connecting Hoses: Compatible Fittings Explained

For seamless connection of hoses with your cleaning equipment, opting for connectors with 1/2-inch or 3/4-inch diameter is critical. The choice depends on your existing hose specifications and intended usage.

Select couplings constructed from durable materials, such as brass or heavy-duty plastic, to ensure a leak-free connection and longevity during rigorous tasks.

When attaching hoses, consider quick-connect couplers for rapid changes. These save time, especially when switching between various tasks or nozzles.

Below is a concise table that lists recommended connectors and their characteristics:

| Type | Material | Size | Usage |

|---|---|---|---|

| Quick-Connect Coupler | Brass | 1/2 inch | Fast hose transitions |

| Threaded Adapter | Heavy-Duty Plastic | 3/4 inch | Multi-use compatibility |

| Barbed Connector | Brass | 1/2 inch | Secure hose attachment |

| Garden Hose to Pressure Connector | Plastic | 3/4 inch | Standard garden hose compatibility |

Always ensure fittings are securely tightened to avoid any disruptions during operation. Regular checks on the integrity of these connections will prevent operational issues and promote a smoother experience during cleaning tasks.

Adapters for Pressure Washer Accessories

Choosing the right adapters for cleaning tools is crucial for achieving optimal performance. These connectors allow for seamless integration between various attachments and the main unit. Here are some common types of adapters that I recommend based on my extensive experience.

Types of Adapters

- Screw-On Adapters: Used mainly for connecting nozzles and spinners. Make sure to match the thread size when purchasing.

- Quick Connect Adapters: Ideal for fast attachments and detachments. These are user-friendly and save time during setup.

- Barbed Adapters: Designed for hose connections, commonly found in various configurations. Always confirm the diameter before buying.

- Multi-Connection Adapters: Flexible options that allow for multiple attachments on a single connection, suitable for versatility in tasks.

Compatibility Check

Always verify compatibility with both the main unit and the accessories. For example, some nozzles might require a specific adapter type to fit correctly. Using the wrong connector can lead to leaks or reduced cleaning effectiveness.

When investing in additional tools, consider purchasing a set of adapters to avoid interruptions during cleaning projects. Having a selection on hand ensures that you can easily switch between tasks without hassle.

Identifying Replacement Accessories for Workzone Models

For efficient replacements, focus on the specific dimensions and types compatible with your cleaning device. Typically, you can identify the right parts by measuring the diameter of the existing connections. This often involves using vernier calipers or a simple ruler.

Attachment Compatibility

When sourcing new couplings, ensure they match the threading specifications–standard and metric threads are both common. The common size I’ve encountered is 3/4 inch for hose connections, ensuring a snug fit to prevent leaks. Double-check for compatibility with the existing hoses and attachments to avoid frustration during assembly.

Nozzle Adaptation

For altering nozzle options, be aware of the M22 and quick-connect styles; the majority of models typically utilise one of these types. Having an assortment of adaptable nozzles enhances versatility for different cleaning tasks. Regularly verify the fitment by connecting the nozzles to confirm firm locking without excessive wobble.

Always consult your user manual or manufacturer’s specifications for precise part numbers when replacing components. This guarantees the longevity and performance of your equipment, maintaining its working condition over time.

Maintenance of Pressure Washer Accessories

Regular upkeep of cleaning gear components can significantly enhance their longevity and performance. To maintain connections, I recommend checking for any signs of wear or damage, such as cracks or leaks. If you notice any, replacing those elements is crucial to ensure efficient operation.

Cleaning and Storage Tips

After each usage, it’s beneficial to detach hoses and nozzles, allowing them to dry thoroughly to prevent any buildup of residue or mould. Storing them in a dry, sheltered area will prevent environmental damage. A quick rinse of the accessory surfaces with clean water helps remove any remaining dirt and debris.

Annual Inspection

An annual inspection is advisable to identify any gradual wear over time. Look at the connectors for signs of corrosion or buildup. Regular lubrication of movable parts can enhance their functionality. Using silicone grease on threads can also assist in creating a watertight seal, preventing leaks during operation.

Troubleshooting Fitting Issues with Your Workzone Washer

Check for cross-threading if you experience leaking or difficulty attaching connections. This often occurs when the threads are misaligned during assembly. Carefully realigning the components can resolve the issue.

Assess the O-rings for wear and tear if leaks persist after ensuring proper alignment. A damaged or worn O-ring can compromise the seal, leading to water escaping from joints. Replacing these rings is a simple and effective solution.

If adapter fittings do not connect securely, inspect for dirt or debris in the ports. Cleaning these areas can improve the connection and provide a better seal. Always keep the areas clean to avoid clogs.

In case of disconnections during operation, verify that all components are tightly secured. Vibration from use can sometimes loosen attachments, requiring regular checks and adjustments.

If you encounter compatibility issues with accessories, review manufacturer recommendations, as using the wrong parts can lead to poor performance or damage. Ensure that any adapters or extensions are specified for your model.

For persistent issues with attachments, consult the user manual for troubleshooting tips specific to your model. These manuals often contain vital information regarding common problems and their solutions.

Regular lubrication of moving parts can prevent friction and wear. Using a silicone-based lubricant on O-rings and threads can enhance performance and prolong the lifespan of your connections.

When replacing components, opt for genuine parts whenever possible. Generic alternatives may not provide the same level of quality and may lead to further complications.

Where to Purchase Compatible Fittings and Accessories

For reliable connections and accessories, I recommend sourcing components from reputable retailers, both online and in-store. Major home improvement stores like B&Q and Screwfix typically carry a selection tailored for various cleaning machines. You can also find quality options on e-commerce platforms such as Amazon, where numerous sellers offer direct compatibility information.

Online Marketplaces

Check websites like eBay for second-hand items or sellers clearing out inventory. This can yield unique finds or older models that are no longer in circulation. Be cautious and verify seller ratings and product reviews to ensure you’re purchasing quality components.

Specialty Stores

Local specialty shops focused on outdoor equipment might also stock desired gear. Establishing a relationship with these businesses may grant access to expert advice and exclusive components not readily available elsewhere. Additionally, consider visiting manufacturer websites for direct purchases or promotional offers; this often guarantees compatibility and quality assurance.

FAQ:

What specific fittings are compatible with WorkZone pressure washers?

WorkZone pressure washers typically use standard fittings that are compatible with many common pressure washer accessories. These usually include quick-connect fittings, which allow for seamless attachment and detachment of different nozzles and hoses. It’s advisable to check the specifications of your particular model, as some may require specific sizes or types of adapters to ensure proper connection and functionality.

Are there different nozzle types available for WorkZone pressure washers?

Yes, WorkZone pressure washers support various nozzle types designed for different cleaning tasks. Common nozzle options include high-pressure nozzles for targeted cleaning of tough stains and wider-angle nozzles for larger surfaces. Some models may also feature adjustable nozzles that allow users to modify the spray pattern for specific needs. Always refer to the user manual to find out which nozzles are recommended for your particular pressure washer model.

Can I use hose attachments from other brands with my WorkZone pressure washer?

In many cases, you can use hose attachments from other brands, provided they have compatible fittings. WorkZone pressure washers generally adhere to standard sizes, allowing for cross-compatibility. However, it’s essential to ensure that any attachments meet the pressure specifications of your machine to avoid any damage. It’s a good practice to consult the user manual or contact customer support for confirmation before purchasing third-party attachments.