For optimal performance, I recommend using a high-quality synthetic or mineral-based lubricant specifically designed for high-pressure systems. Look for products that adhere to the ISO VG 46 classification for the best results in your Kärcher cleaning device. This specification ensures the fluid maintains proper viscosity under varying temperatures and operational conditions.

It is crucial to avoid standard automotive oils, as they may not provide the necessary protection and could lead to premature wear of internal components. Always refer to the manufacturer’s manual for specifications. This will guide you in selecting compatible lubricants that meet the requirements of your particular model, ensuring the longevity of your unit.

Regular maintenance is key. I suggest checking the lubrication level frequently and changing it at least once a year or after every 100 operating hours. Keep an eye out for any signs of leakage or unusual noises, as these can indicate that the system requires attention. By following these guidelines, you can maintain your unit efficiently and extend its lifespan.

Recommended Lubricant for Karcher Equipment

For optimal performance of your Karcher machine, I highly recommend using a high-quality 15W-40 multi-grade liquid developed for small engines. This type of lubricant provides reliable protection, ensuring smooth operation and extending the lifespan of internal components.

Look for products specifically labelled as suitable for pressure cleaning devices or similar applications. Note that synthetic alternatives also exist, offering better performance in extreme temperatures. Always check the manufacturer’s guidelines for requirements and avoid using automotive oils, as they may contain detergents harmful to these systems.

Regularly inspect the lubricant level, and top it up as necessary to maintain proper functioning. A good practice is to change the lubricant at least once a year, or more frequently if you use the equipment heavily. Cleaning the pump and ensuring the correct viscosity will further enhance reliability and effectiveness during use.

Understanding the Importance of Pump Oil

Choosing the right lubricant for the internal mechanism of your cleaning device plays a critical role in its longevity and performance. The internal components depend on a specific type of lubrication to ensure smooth operation and to reduce wear and tear. A high-quality fluid will facilitate friction reduction, enhancing efficiency while also protecting against corrosion and rust.

Inconsistent lubrication can lead to overheating and stress on the internal parts, potentially resulting in system failure. Regular checks and timely replacements based on usage frequency can prevent costly repairs. Proper understanding of the recommended viscosity and compatibility with your unit is paramount. Something as simple as using an inappropriate blend can drastically impact the performance.

Key Benefits of Proper Lubrication

| Benefit | Description |

|---|---|

| Enhanced Performance | Optimised lubricants maintain system efficiency, ensuring effective cleaning results. |

| Corrosion Protection | Adequate lubrication prevents rust formation, promoting the unit’s lifespan. |

| Reduced Wear | Correct viscosity minimises friction, decreasing the rate of component degradation. |

| Thermal Regulation | Quality fluid aids in heat dissipation, preventing overheating and breakdown. |

Always consult the user manual for specific recommendations regarding lubrication maintenance. Proactively maintaining your washing apparatus, including using the appropriate lubricant, will ensure optimal performance and extend the operational life of your equipment.

Types of Oil Suitable for Karcher Pressure Washers

The recommended choices for lubricants include both synthetic and mineral varieties. Synthetic fluids offer enhanced stability and can better withstand extreme temperatures, prolonging the lifespan of your machinery. On the other hand, mineral-based options provide reliable performance for less demanding tasks.

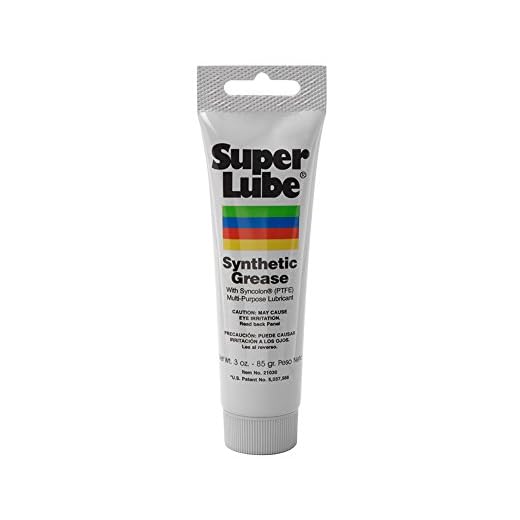

Synthetic Lubricants

Synthetic products, like SAE 30 or SAE 40, are particularly advantageous if you operate in varied conditions. Their formulation ensures excellent lubrication under pressure and reduces wear on internal components. Look for those specifically designed for high-performance cleaning devices to achieve optimal results.

Mineral-Based Alternatives

If you prefer traditional options, consider using high-quality mineral oils with an appropriate viscosity rating. These oils can adequately protect and lubricate without breaking down, making them suitable for everyday cleaning activities. Be sure to verify compatibility with your specific model before application.

Always follow the manufacturer’s specifications regarding viscosity and change intervals to maintain machinery health. Regular checks can help you catch any issues early, ensuring your equipment continues to perform at its best.

How to Check Oil Levels in Your Equipment’s Pump

Start by locating the oil reservoir on your machine. It’s typically a small cap marked clearly, often found near the engine area. Ensure the unit is on a level surface to get an accurate reading.

Unscrew the cap carefully and wipe the dipstick with a clean cloth. Reinsert it without screwing it back in to check the level. The fluid should be between the minimum and maximum indicators. If it’s below the minimum mark, it’s time to add more liquid.

Adding New Fluid

If you need to replenish, choose a high-quality product suitable for your model. Pour slowly to avoid overfilling, checking the level periodically until it reaches the desired mark. After you’ve filled it, securely replace the cap before operating the equipment.

Regular Maintenance Checks

Incorporate reading the fluid levels into your regular maintenance routine. I recommend checking them each time you use the machine or at least monthly during upkeep. This could prevent operational issues and prolong the lifespan of your equipment.

Step-by-Step Guide to Changing Pump Oil

To maintain optimal performance, regularly replacing the liquid in your cleaning device’s mechanism is vital. Here’s how to do it correctly:

1. Gather Your Supplies

Before starting, assemble necessary tools: a suitable replacement fluid, a clean funnel, a container for the old liquid, and a cloth for cleanup.

2. Prepare the Equipment

Disconnect the appliance from the electrical source. This ensures safety while working on the device. Allow it to cool if it has been in use recently.

3. Locate the Drain Plug

Identify the drain plug, usually found at the bottom of the mechanism. It may require a wrench for removal. Ensure you have your container ready to catch the old liquid.

4. Drain Old Liquid

Carefully unscrew the drain plug and allow the used fluid to flow into the container. Make sure to dispose of the old liquid according to local regulations.

5. Refill with New Substance

Using the funnel, pour the fresh lubricant into the fill hole until it reaches the recommended level. Avoid overfilling, as this can cause pressure issues.

6. Secure Everything

Reattach the drain plug tightly. Check for any leaks around the plug. Wipe any spills with a cloth to prevent slipping and damage.

7. Test the Appliance

Reconnect to the power supply and run the device briefly to ensure everything operates smoothly. Listen for any unusual sounds that could indicate a problem.

By following these steps, you can ensure your cleaning apparatus runs efficiently, extending its lifespan and performance.

Common Mistakes When Choosing Pressure Washer Oil

The selection of lubricant for your cleaning equipment can dramatically affect its longevity and performance. One prevalent error is opting for automotive grades instead of dedicated products, which lack the necessary additives for high-pressure systems. This can lead to premature wear or failure.

Overlooking Viscosity Ratings

Matching the viscosity rating to your device’s specifications is crucial. A common misstep is using an incorrect viscosity, potentially causing inefficiencies in operation. Refer to the manufacturer’s guidelines for the appropriate rating, ensuring optimal flow and protection under varying temperatures.

Ignoring Synthetic Options

Another frequent oversight is disregarding synthetic lubricants. Many assume conventional varieties suffice; however, synthetics offer enhanced protection and better performance at extreme conditions, thus proving more beneficial in the long run.

Signs You Need to Change the Oil in Your Pump

Regularly checking the performance indicators of your equipment will help you determine the right time for an oil change. Here are some specific signs to monitor:

- Discoloration: If the liquid appears dark or cloudy, it could indicate contamination or degradation.

- Strong Odour: A burnt or unusual smell is a clear sign that the lubricant is no longer effective.

- Excessive Noise: Increased operational sounds may suggest inadequate lubrication.

- Decreased Performance: Noticeable drops in power or efficiency during operation should raise concern.

- Visible Leaks: Any signs of leakage from seals or joints can compromise lubrication.

Recommended Frequency for Changes

It’s advisable to replace the liquid annually or after a specified number of operational hours, depending on the manufacturer’s guidelines. Keeping a maintenance log can assist in tracking these intervals effectively.

Pay attention to the surroundings; high dust or debris environments may necessitate more frequent changes due to increased contamination risks.

Where to Purchase Recommended Pump Oils

Local hardware stores offer an excellent selection. Visiting these stores allows for direct interaction with staff, who can provide expertise on suitable lubricants for your equipment. Check these retailers:

- B&Q

- Homebase

- Wickes

Online retailers expand your options significantly. Websites like Amazon and eBay feature a variety of brands and types in various quantities. Look for user reviews to gauge product effectiveness.

Specialty Shops

Stores focused on gardening or cleaning supplies often stock recommended products. They may carry brands like:

- Nilfisk

- Annovi Reverberi

- Husqvarna

Manufacturer Websites

Directly purchasing from manufacturers’ sites ensures authenticity. Many brands provide insights on specific lubricants designed for their products, often accompanied by promotions or bulk deals.

Lastly, don’t overlook local auto parts stores. Some engine oils are versatile and compatible for certain cleaning devices. Always verify the specifications for compatibility before the purchase.