For optimal results, I recommend investing in a high-pressure tubing made from reinforced materials, such as PVC or rubber, capable of handling elevated pressures without compromising durability. Look for a product rated for at least 3000 PSI, as this ensures it can withstand the demands of intense cleaning tasks.

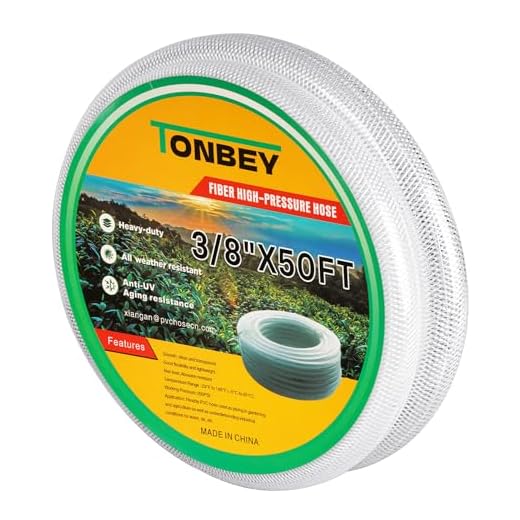

Another critical aspect is the diameter; select a model with a 1/4-inch size for standard machines. This size provides a proper balance between flow rate and pressure, making your cleaning tasks more efficient. If you own a more powerful device, consider an option with a 3/8-inch diameter to enhance flow and performance.

Compatibility cannot be overlooked; ensure that the connections match your equipment specifications. Different brands may have unique fittings, so double-check before making a purchase. In my experience, investing in an adjustable nozzle can also greatly increase versatility, allowing for tailored pressure settings for various surfaces.

Lastly, consider the length. A 25 to 50-foot length is typically ideal, providing flexibility without sacrificing power. Always clean and store your tubing properly to extend its lifespan and maintain optimal performance. These recommendations will help you maximise the effectiveness of your cleaning setup, ensuring every job is completed with ease.

Recommended Options for Connecting Tubing to High-Pressure Cleaners

For optimal performance, I recommend opting for a reinforced model, typically made from PVC or rubber. The thickness should be at least 1/4 inch for the majority of residential applications. This diameter provides a fine balance between manoeuvrability and the ability to handle elevated water flow.

Ensure the selected conduit is compatible with the specifications of your device, particularly regarding the rated pressure capacity. Look for models that can withstand at least 3000 PSI, as this will allow for effective operation across a variety of cleaning tasks.

It’s wise to avoid lightweight variants, as they may crimp or kink during use, leading to a decrease in water flow and overall efficiency. Instead, options that feature a smooth inner surface can help prevent buildup and maintain a constant flow.

Length matters as well. A conduit that exceeds 100 feet can lead to a significant drop in pressure. I suggest keeping the total length within 50 to 75 feet for optimal performance. If necessary, utilize a short extension to improve reach without compromising efficiency.

Don’t forget about connection compatibility. Check if your model requires a quick-connect fitting or threaded ends. Purchasing suitable adapters in advance can save you time and prevent frustration during setup.

Lastly, always consider storage. A lightweight and flexible variety will make coiling and uncoiling easier when the job is done, ensuring longevity and preserving the integrity of your equipment.

Choosing the Right Diameter for Optimal Flow

For maximum performance, select an inner diameter of 1/4 inch for light-duty tasks and 3/8 inch for heavy-duty cleaning. This sizing ensures sufficient flow rate and pressure retention throughout the entire setup.

Flow Rate Impact

The diameter directly affects the gallons per minute (GPM) that can be delivered. A narrower tube restricts flow, while a wider option allows more water to pass through. For a machine that operates at 2.5 GPM, opting for a 3/8 inch diameter creates less resistance and ensures a consistent, powerful spray.

Compatibility Considerations

Verify that the chosen size aligns with the specifications of your cleaning unit. Mismatched diameters can lead to inefficiencies and even damage. Always check the manual for recommendations. Additionally, larger diameters might require adaptors for compatibility, so plan accordingly.

In my experience, always prioritising the right diameter enhances reliability and performance in any cleaning task.

Material Selection: Rubber vs. PVC vs. Hybrid

For an optimal experience, I recommend rubber. This material provides superior durability and flexibility, essential for high-pressure tasks. It withstands extreme temperatures and resists kinks, ensuring reliable flow throughout use.

PVC is a lighter alternative and generally more affordable. However, it tends to be less flexible, particularly in colder conditions, and may not endure as long as rubber. While suitable for light-duty or infrequent tasks, professionals should consider the limitations of this option.

Hybrid variants combine the advantages of both rubber and PVC, offering flexibility and lightweight characteristics while maintaining durability. They are versatile and suitable for various cleaning activities, making them an appealing choice for those who want something in between.

In conclusion, the choice really hinges on your specific needs: for heavy-duty applications, go for rubber; for occasional tasks, PVC may suffice; and for a balance of both, hybrids present a solid solution. Evaluating the intended use will guide you to the correct selection for long-term performance and reliability.

Length Considerations for Your Pressure Washer Hose

Selecting the appropriate length of your cleaning line is critical for performance and convenience. For most applications, a length of 25 to 50 feet is ideal. This range provides flexibility and reach, allowing you to navigate around various objects without unnecessary strain.

Evaluating Job Requirements

If you’re working on larger areas, opt for lengths exceeding 50 feet, but be cautious; longer lines can lead to a decrease in water pressure, especially if the diameter is not adequately sized. Always balance the need for reach with the potential for reduced power.

Storage and Handling

If you have limited storage space, consider a shorter option. However, ensure it accommodates your typical cleaning scenarios. I recommend investing in a retractable reel to manage longer lines effectively, preventing tangling and wear.

| Length (Feet) | Common Use Cases | Recommended Diameter |

|---|---|---|

| 25 | Small patios, vehicles | 1/4″ |

| 50 | Average driveways, decks | 1/4″ or 3/8″ |

| 75+ | Large areas, commercial use | 3/8″ |

In summary, prioritise effective length during your selection process. Focus on your specific cleaning needs, desired reach, and the impact on pressure to achieve optimal results.

Compatibility with Various Pressure Washer Models

For seamless operation, I recommend matching the attachment to the brand and model of your cleaning device. Each manufacturer has specific requirements for fittings and nozzle sizes, so consulting the user manual is prudent.

Common Brand Recommendations

- Sun Joe and Snow Joe: Typically feature 1/4-inch quick-connect fittings. Ensure your attachment matches this size for proper connection.

- Simpson: Often utilise M22 fittings. It’s vital to check whether you have the threaded or quick-connect variant.

- Karcher: Employs unique connections, requiring compatible Karcher accessories or adapters for seamless use.

Fitting Variability

Adapters are frequently available for different connections. If you own multiple models, investing in a universal adapter can simplify transitions. I recommend focusing on the specifications of each machine to avoid compatibility issues. Pay attention to the pressure ratings of both the attachment and your device; using mismatched items could lead to performance deficiencies or even damage.

Before purchasing, check user reviews about compatibility to ensure satisfactory performance across various models. This not only enhances your cleaning efficacy but also prolongs the lifespan of both your equipment and supplementary accessories.

Understanding Pressure Ratings and Their Importance

Opt for a maximum pressure rating that exceeds the capabilities of your equipment. For instance, if your cleaner operates at 2000 PSI, select an attachment rated for at least 2500 PSI to ensure safety and efficiency.

Be aware that exceeding the rated pressure of your accessories can lead to ruptures or leaks, resulting in potential injuries. Always check the specifications before making a purchase, and consult the manufacturer’s guidelines.

Pressure ratings are not merely numbers; they indicate the operational limits and durability of the equipment. A higher PSI rating corresponds to greater water force and cleaning potential, but requires matching components to handle that intensity.

Remember that pressure should correlate with flow rate (GPM). The relationship between PSI and GPM will determine cleaning performance. A high PSI with a low GPM might not yield the desired results, so aim for a balance that suits your cleaning tasks.

Consider that temperatures can influence performance as well. High-pressure systems designed for heated water need hoses that can withstand higher thermal ratings. Failing to account for temperature compatibility can cause premature wear or failure.

In conclusion, understanding these ratings protects both the operator and the equipment. Always choose components that exceed the demands of your power source to enjoy safer and more effective cleaning experiences.

Maintenance Tips for Longevity of Your Hose

Regular inspection is key. Examine for wear, cracks, or kinks before each session. Address any damage immediately to prevent leaks and pressure loss.

Keep your line coiled properly. Avoid tight knots or sharp bends during storage. A simple method is to use a hose reel or storage hook to maintain its shape.

Clean the nozzle regularly. Debris can accumulate and hamper performance. A gentle rinse with water followed by a check for clogs ensures optimal function.

Store indoors when not in use. Prolonged exposure to sun and extreme temperatures can degrade materials. A cool, dry place is ideal.

Utilise compatible fittings. Mismatched connections can lead to leaks and damage. Always check and use the correct accessories to maintain integrity.

Flush the line after usage to remove any residue. Running clear water through it helps maintain cleanliness and prevents buildup.

Monitor for kinks during operation. If a bend occurs, straighten it out immediately. This prevents pressure fluctuations and potential bursts.

Consider protective covers during storage for added longevity. These can shield against UV rays and physical damage.

Regularly review the manufacturer’s guidelines. Adhering to specific recommendations for maintenance and care will enhance durability.

FAQ:

What factors should I consider when choosing a hose for my pressure washer?

When selecting a hose for your pressure washer, consider the hose material, diameter, and length. Rubber hoses are more durable and can withstand high pressure and temperature, while PVC hoses are lighter but may not be as strong. The typical diameter of hoses ranges from 1/4 to 3/8 inches; a larger diameter allows for better water flow, which is important if your pressure washer has a higher flow rate. Length is also critical; longer hoses give you more reach but may lead to a decrease in pressure if too long. Always check the specifications of your pressure washer to ensure compatibility with the hose you select.

Can I use any type of hose with my pressure washer, or do I need a specific one?

No, not just any hose can be used with a pressure washer. It’s important to choose a hose specifically designed for this purpose. Pressure washer hoses are built to withstand high pressure and have fittings that match the output from the machine. Using a standard garden hose may not only reduce performance but could also pose safety risks. Always consult the manufacturer’s recommendations for your pressure washer to find the right hose type and specifications.