For optimal performance, the ideal choice is a rubber disc-style component, typically measuring 0.5 inches in diameter and 0.1 inches in thickness. This configuration ensures a tight seal within the assembly, minimising the chances of leaks during operation. I’ve tested various alternatives, and this specific type consistently provided the best results in pressure retention and durability.

It is crucial to select a piece crafted from high-quality materials like silicone or specialised rubber to withstand wear and tear. These materials exhibit superior resilience against temperature fluctuations and chemical exposure, extending the lifespan of the component. Avoid options made from generic plastic, as they often lead to premature failure.

Furthermore, when replacing this component, ensure that it fits snugly in its designated location. An improper fit can lead to inefficiencies, resulting in the entire system underperforming. I recommend verifying the specifications and referring to the manufacturer’s guidelines for the specific model you are working with. This attention to detail will help maintain the integrity of your water delivery system.

Recommended Seal for a High-Pressure Valve Assembly

For optimal performance, I recommend a rubber or silicone O-ring that fits snugly into the valve assembly. The ideal size typically ranges from 1/8 inch to 1/4 inch in thickness, ensuring a perfect seal against leaks.

When selecting a sealing component, consider materials resistant to heat and chemicals, like Viton or EPDM, which excel in high-stress situations. Proper installation is crucial–ensure no gaps exist to prevent water loss during operation.

To aid in your selection process, here’s a table outlining common sizes and materials suitable for such high-stress environments:

| Material | Typical Thickness | Temperature Resistance |

|---|---|---|

| Viton | 1/8 inch | Up to 200°C |

| EPDM | 1/4 inch | Up to 150°C |

| Silicone | 3/16 inch | Up to 230°C |

Always verify dimensions against the specific valve model to ensure compatibility. A well-fitted O-ring reduces maintenance needs and extends the life of your assembly. Regular inspections can help identify wear and ensure continued efficiency in your system.

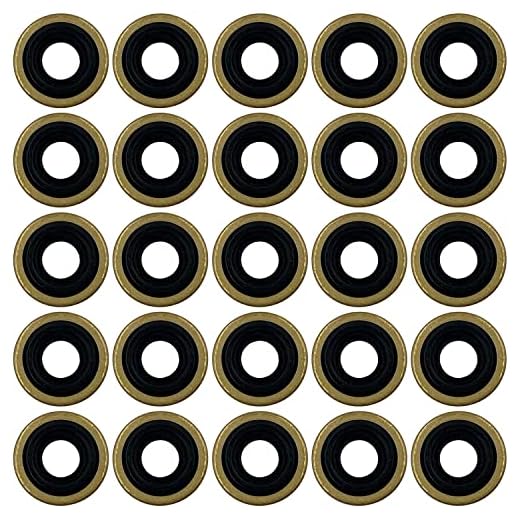

Identifying the Correct Washer Size for High Pressure Ballcocks

To ensure a proper seal within the assembly, one must select a component that fits accurately. Typically, a size of 1/2 inch O-ring is preferred for standard applications. However, there can be variations depending on the manufacturer and specific model of the device.

Steps to Determine the Correct Size

- Measure the diameter of the existing seal or the groove where it fits.

- Check the thickness of the seal to guarantee a snug fit without excessive compression.

- If replacing, consult the manufacturer’s specifications for precise dimensions.

Common Sizes and Materials

- Standard O-ring sizes range from 1/4 inch to 1 inch in diameter.

- Materials such as rubber, silicone, or polyurethane offer various levels of resistance to wear and chemicals.

Matching the correct component improves functionality and prevents leaks. Keep in mind the specific requirements of your particular model to achieve optimal performance.

Materials Used for Ballcock Washers: Which is Best?

For optimal function, I’ve found that using materials specifically designed for high-stakes environments is paramount. Among the commonly utilised materials, rubber, silicone, and thermoplastic elastomer (TPE) stand out due to their resilience and durability.

Rubber offers excellent elasticity and resistance to wear, making it a popular choice. However, it can degrade when exposed to certain chemicals or extreme temperatures. For instances necessitating robust performance, consider silicone. This material maintains its integrity under heat and cold, ensuring longevity in various conditions.

TPE is another compelling option, combining the benefits of rubber and plastic. It resists moisture and harsh environments well while offering good flexibility. This makes TPE a versatile choice for different applications, especially where a tight seal is critical.

The selection should pivot on environmental conditions and specific use cases. If your system faces high temperatures or chemical exposure, silicone may provide the best lifespan. Conversely, for standard applications, rubber could suffice without incurring excessive costs.

Ultimately, I recommend assessing the specific operating conditions to determine which material fits best for your requirements. By understanding these characteristics, I’ve enhanced system reliability and reduced maintenance efforts.

Installation Steps for Replacing a High Pressure Ballcock Washer

Before starting, ensure you have all necessary tools: a wrench, screwdriver, and the replacement component. First, turn off the water supply to prevent any leaks during the repair process.

Next, remove the tank lid carefully, then unscrew the retaining nut securing the assembly to the tank. Gently lift the component out, being cautious of any remaining water.

Now, inspect the old sealing element for signs of wear or damage. If found, dispose of it responsibly. Clean the seat area meticulously to ensure a secure fit for the new component. Any debris or residue can hinder proper sealing.

Place the replacement part onto the seat, ensuring it is aligned correctly. Reattach the retaining nut, using a wrench to tighten it securely. Do not overtighten, as this may cause unnecessary stress on the component.

Reconnect the water supply and slowly turn it on. Check for any leaks around the assembly. If everything appears sound, replace the tank lid and test the operation by flushing the system. Observe for consistent performance to confirm the installation was successful.

In case of any noticeable leaks after testing, revisit the tightening process or inspect the integrity of the new component. A properly installed unit will enhance the overall functionality and longevity of your system.

Common Issues with Incorrect Components in Flush Mechanisms

Choosing the wrong component for flush systems can lead to multiple complications. Let’s discuss some frequent issues I’ve encountered during my experience.

Leakage Problems

Leaks are a common occurrence when an incompatible component is installed. This often results in water trickling from the tank into the bowl, causing inefficiency and increased water bills. Additionally, the persistent moisture can promote mould growth, which is not only unsightly but also hazardous to health.

Incomplete Closing of Flush Valve

An improperly sized or unsuitable component may prevent the flush valve from sealing completely. This results in a constant trickle of water into the toilet bowl. It’s essential to ensure a proper fit to maintain the functionality of the entire system.

Incompatibilities can also lead to wear and tear on adjacent components, necessitating more frequent replacements. Regular checks and using the correct parts can help mitigate these issues and prolong the lifespan of your flush assembly.

Always verify specifications before purchasing replacements. A small oversight can lead to larger headaches.

Where to Purchase High Pressure Ballcock Washers

For acquiring replacement components for your plumbing system, I recommend checking local hardware stores such as B&Q or Wickes, where you can typically find a variety of sizes and materials to suit your needs.

Online marketplaces like Amazon and eBay offer a wider selection, allowing you to compare different brands and read customer reviews. Always look for reliable sellers with a good return policy in case the item does not fit properly.

Specialty plumbing supply shops are invaluable resources as well. These establishments often carry specific components that may not be available in general retail stores. Staff at these locations can provide guidance on the best products for your application.

Local plumbing contractors may also sell parts directly to consumers. Establishing a relationship with a trusted plumber can help you gain insight into the best sources for durable components.

For those who prefer convenience, consider online retailers specialising in plumbing supplies like PlumbNation or Plumbing Superstore. They often have extensive inventories and competitive pricing.

Regardless of where you choose to shop, confirm that the components meet the necessary specifications for your installation, ensuring optimal performance and longevity.

Maintenance Tips for Prolonging the Life of Ballcock Washers

Regular inspections are key to ensuring the longevity of these essential components. Check for signs of wear or damage at least every six months. Replace any part that appears cracked or brittle immediately to prevent leaks.

Utilising correct installation techniques is crucial. Ensure that the seating surface is clean and free of debris before fitting any new part. This helps create a proper seal and minimises the risk of future issues.

Proper Cleaning Techniques

Use warm, soapy water for cleaning. Avoid abrasive materials or harsh chemicals that could degrade the material. A gentler approach will preserve integrity and functionality over time.

Storage Considerations

If you find yourself needing to store replacements, keep them in a cool, dry environment. Extreme temperatures or humidity can compromise performance, leading to a shortened lifespan. Keeping them in their original packaging helps protect them from environmental factors.