For those aiming to troubleshoot issues with their cleaning device, identifying the position of the pressure sensor is fundamental. On many models, this component is commonly situated at the rear of the unit, usually near the water inlet valve. It’s advisable to disconnect power and water supply before beginning any inspection or repair work.

After ensuring safety measures are in place, take a closer look behind the back panel. Depending on your model’s design, you might need to remove a few screws to access it. Typically, the sensor is housed in a plastic casing, which can often be differentiated by its cylindrical shape and the presence of rubber tubing connected to it.

Once located, inspect for any signs of blockage or damage. If performance issues persist, consider testing the sensor with a multimeter to ensure it functions as intended. This proactive approach can often save time and ensure your appliance operates efficiently.

Locating the Pressure Sensor in Your Appliance

To find the sensor responsible for water level detection, first, unplug the unit to ensure safety. Open the front or rear panel, depending on your model. Look near the bottom where the water chamber is located; it’s usually mounted on the side of the tank or connected to a hose leading to it. This component often appears as a small cylindrical device. Make sure to check behind any insulation to spot it correctly.

Steps for Accessing the Sensor

1. Remove screws or clips securing the outer casing.

2. Gently lift the panel to reveal internal components.

3. Identify the water level monitoring device by tracing the hose connected to it.

4. Inspect for any visible damage or blockages on the connections.

Once located, you can clean or replace the unit if necessary. Always consult your user manual for specific diagrams and additional instructions tailored to your particular model.

Troubleshooting Tips

If you’re experiencing issues with water levels not being detected accurately, check the elasticity of the hose connected to the sensor. Ensure it’s not kinked or clogged. In some cases, the internal diaphragm may require replacement. Testing with a multimeter can also confirm if the sensor operates within the required parameters.

Maintaining this part is key for optimal performance of your appliance and ensuring efficient operation during each cycle.

Understanding the Role of the Pressure Switch

In modern laundry appliances, the component responsible for monitoring water levels plays a pivotal role. This device detects the presence of water within the drum, ensuring optimal functionality throughout the washing cycle. It sends signals to the control board, allowing accurate management of different washing phases.

Functionality and Importance

This device works by using air pressure to gauge water levels. When the drum fills with water, air pressure in the tube connected to this component varies, triggering a response that either engages or disengages the water inlet valve. This precise measurement helps prevent overflows and ensures that the machine operates under safe conditions.

Common Issues and Troubleshooting

Problems with this essential part can lead to malfunction, such as improper filling or draining. If you encounter issues, check the connecting hose for blockages or leaks, as these can affect the device’s ability to pressure-read accurately. Testing for electrical faults may also determine whether the appliance requires repair or replacement of the component.

Typical Locations for the Pressure Sensor in Hotpoint Models

In many cases, this component can be found at the back of the appliance, near the water inlet valve. This location allows for effective monitoring of water levels inside the drum. Alternatively, some designs feature it on the side panel, which facilitates access during maintenance.

Common Arrangements

Several models may house this device beneath the top panel, secured with screws. This setup ensures minimal interference from other parts, but it may require removing the top for inspection. Additionally, certain variants incorporate a tube that connects to the drum; this hose is critical for accurate readings.

Tips for Locating

Consult the user manual for your specific model to confirm the exact location. If access is difficult, I suggest using a flashlight to aid visibility, as these components are often tucked away in less accessible areas. Identify any plastic covers that may need removal to gain full access.

Step-by-Step Guide to Access the Pressure Switch

Gather necessary tools: a screwdriver set, a multimeter, and safety gloves. Make sure to unplug the unit to avoid any electrical hazards.

First, remove the back panel. Locate screws along the edges, using the appropriate screwdriver to take them out. Store screws safely for reassembly.

Next, inspect the layout inside. The component can typically be found near the water inlet valve, usually attached to a plastic housing. Trace any connected tubing running to this assembly.

Disconnect any wires linked to the component carefully. Use a multimeter to check for continuity, ensuring that no further tests are needed before replacement.

If modifications are necessary, carefully detach the component from its mounting. Be gentle during this process to avoid breaking any plastic clips or connectors.

Once removed, compare it with the new item to confirm compatibility. Reattach the new component in the same position, ensuring all connections are tightened securely.

Reassemble the back panel by replacing screws in their original positions. Plug the unit back in and conduct a test cycle to ensure functionality has been restored.

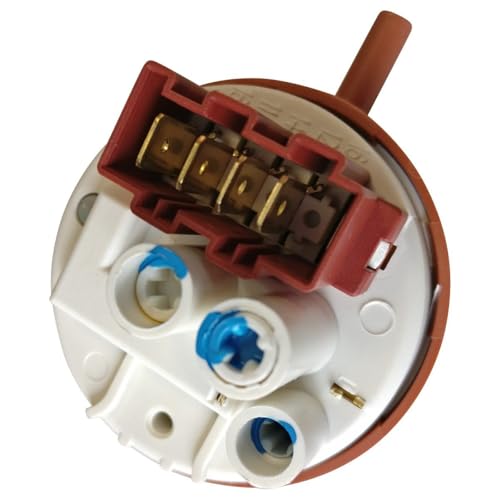

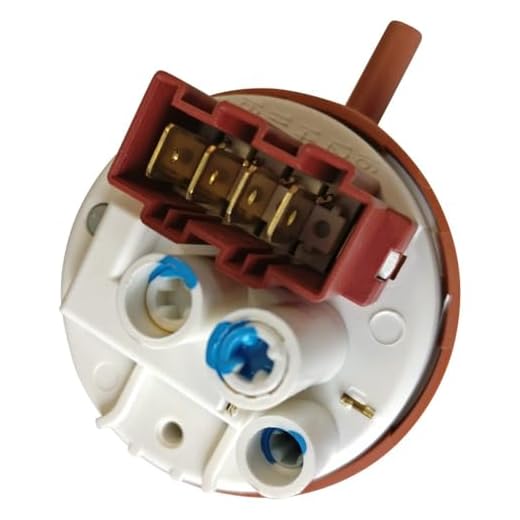

Identifying the Pressure Switch by Appearance

To recognise a control mechanism in a laundry machine, focus on its distinct features. Typically, this component is compact, featuring a round or oval shape. It is often constructed from durable plastic material to withstand the environment inside the appliance.

Key Characteristics

- Size: Generally small, about 2 to 4 inches in diameter.

- Connector: Usually includes a couple of wiring terminals for electrical connections.

- Tube Entry: Essential to note the presence of a small rubber or plastic hose connecting it to the water chamber within the device.

- Markings: Look for labelling or model numbers that can aid in identification, often found on the body of the unit.

Colour and Texture

- Common colours include black, grey, or white, depending on the model.

- The surface is primarily smooth, which can aid in cleaning if accessed.

By focusing on these specific traits, identifying this important control element becomes easier, ensuring accurate assessment and maintenance of the laundry unit’s functionality.

Troubleshooting Common Issues with the Pressure Switch

If water is not reaching the drum as expected, it may indicate a malfunction. Start by checking the tube connected to the sensor. Ensure it is clear of blockages or leaks. A clogged tube can hinder proper function, leading to inaccurate readings.

If your appliance fails to begin a cycle, inspect the wiring leading to the component. Look for loose or damaged connections. Repair or replace faulty wiring to restore communication between the part and the control board.

Diagnosing Performance Problems

Listen for clicking sounds during operation–this may suggest the component is trying to engage but failing. If you hear no sounds, a definitive failure in the component could be present. Testing with a multimeter can identify whether the device is receiving power correctly.

Be wary of false alarms where the appliance indicates the drum is full when it is not. This can derive from a malfunctioning component, causing it to register incorrect water levels. Replacing the sensor may be required to remedy this.

Steps to Rectify Issues

Firstly, unplug the appliance before performing any checks. Clean connections, applying lubricant if necessary to prevent corrosion. If problems persist after addressing these points, consider replacing the component entirely. This typically resolves persistent issues.

Replacing the Pressure Sensor: What You Need to Know

Before starting any replacement, ensure that the appliance is unplugged. This is a crucial safety step. You’ll need basic tools: a screwdriver set, pliers, and possibly a multimeter for testing. Familiarise yourself with the specific model’s manual for additional guidance on components and wiring diagrams.

Steps for Replacement

Remove any access panels to gain visibility of the internal assembly. Look for the sensor, usually located near the water inlet. Disconnect the tubing carefully to avoid damaging the connectors. Generally, you’ll need to unscrew or unclip the sensor itself from its mounting bracket.

When fitting the new component, make sure to connect it to the same wiring configuration as the old unit. Ensure the tubing is securely connected to prevent leaks. After replacement, replace all access panels and reconnect the power supply.

Testing Post-Replacement

Once installed, run a short cycle to test for functionality. Observe the water levels and operation during this test. If issues persist, recheck connections and ensure that there are no blockages that might affect performance.

| Tool | Purpose |

|---|---|

| Screwdriver Set | To remove access panels and secure brackets |

| Pliers | To grip and disconnect tubing |

| Multimeter | To test electrical connections if needed |

Following these guidelines ensures a smooth and safe replacement process. Always consult your specific model’s manual for any peculiarities related to your appliance.

Maintaining the Pressure Switch for Long-Term Performance

Regular upkeep can significantly extend the lifespan and functionality of your appliance. Here are some targeted recommendations to ensure optimal operation:

- Inspect Regularly: Check for any signs of wear or damage at least once every six months. Physical inspection helps identify potential issues before they escalate.

- Clean Connection Points: Ensure that the connectors are free from dust and debris. Use a soft cloth or compressed air to clean around the terminals and tubing.

- Avoid Overloading: Adhere to the manufacturer’s guidelines regarding load limits. Overloading can cause strain and lead to malfunctions.

- Monitor Water Quality: Use filtered water if possible, as minerals and contaminants can compromise internal components over time.

- Check for Leaks: Examine hoses and seals for any signs of leakage. Addressing leaks promptly prevents further complications.

Periodic maintenance not only enhances performance but also reduces the likelihood of costly repairs or replacements. Additionally, consider keeping a service schedule to stay on top of these tasks.

Investing time in maintaining this component will yield better results and prolong the effectiveness of your equipment.