One of the most common issues I have observed is diminished water force during operation. If you’re experiencing this problem, I recommend checking the nozzle first. A clogged or worn nozzle can significantly reduce performance. Ensure it’s clean and replace it if necessary.

Next, examine the hose for any kinks or damages. Any obstruction in the hose can hinder water flow and reduce pressure. Verify all connections are secure and free from leaks. A loose connection may also lead to decreased output.

If the problem persists, consider the water source. Insufficient supply or low pressure from the tap can affect your equipment’s performance. Always verify that your water source meets the necessary requirements for optimal function.

Lastly, inspect the internal components of the unit. A malfunctioning seal or faulty pump can contribute to insufficient output. Regular maintenance is essential for the longevity of your equipment, so conduct routine checks to prevent future issues.

Checking for clogged nozzles

Inspect the nozzle for any blockages. Accumulated dirt or debris can significantly restrict flow, impacting performance.

Follow these steps to ensure optimal function:

- Turn off the machine. Safety is paramount.

- Remove the nozzle from the lance. Depending on the model, this may require unscrewing or simply pulling it off.

- Examine the nozzle for visible clogs. Use a flashlight if necessary for a closer look.

- If dirt is present, clean it using a soft brush or cloth. Avoid abrasive materials that could scratch or damage the nozzle.

- Create a mixture of warm water and mild detergent. Soak the nozzle for a few minutes if clogs persist.

- After soaking, rinse thoroughly under running water to remove any remaining residue.

- Check for a specific nozzle size or pattern that suits your tasks. Sometimes, switching to a different nozzle can enhance effectiveness.

After cleaning, reattach the nozzle and test the unit. If performance has not improved, further investigation may be required.

Inspecting the Water Supply Source

Examine the water supply closely. A restricted flow can lead to inadequate performance. Begin with the water source itself–ensure the tap is fully opened. If you’re connected to a hose, check for kinks or bends that could limit water access.

Testing Water Flow

Fill a bucket with water from the tap to check the flow rate. A good benchmark is at least 10 litres per minute. If the flow is below this, you may need to consider an alternative water source or repair existing plumbing issues.

Assessing Hose Condition

Inspect the hose for blockages or damage. A clogged inlet filter can also impede water intake. Remove any filters and clean them thoroughly to allow free passage of water. Replace damaged hoses to restore performance.

| Problem | Recommended Action |

|---|---|

| Low water flow from tap | Check and fully open the tap, or switch to another source. |

| Kinked or damaged hose | Unkink the hose or replace it if torn. |

| Clogged inlet filter | Clean the filter thoroughly or replace if necessary. |

Following these checks, return to operation. Should performance issues persist, further investigation into the system may be necessary.

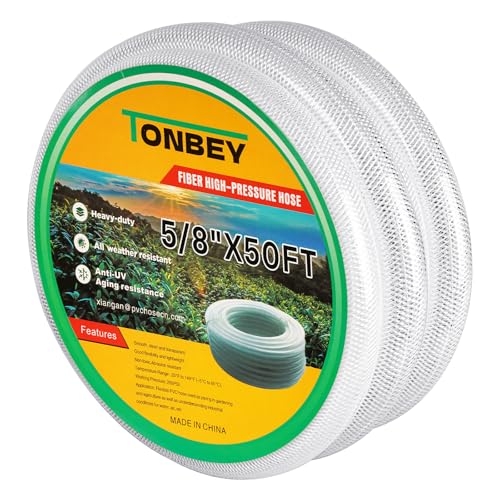

Examining the pressure hose for damage

.jpg)

Inspect the hose for any signs of wear, such as cracks, bulges, or leaks. A damaged hose can cause significant loss of water pressure, affecting performance. Check for kinks and twists that may restrict flow; these can easily occur during use or storage.

When looking for leaks, run your hand along the length of the hose while the unit is pressurised. Pay special attention to the connections at both ends, as these areas are prone to failure. If water seeps from any joint, replace the hose immediately.

Extend the hose fully during your inspection to reveal hidden damages, which might be masked when coiled. If you notice any issues, do not attempt to repair the hose with tape or other quick fixes, as this can lead to further complications. Acquiring a new hose ensures consistent water flow and optimal performance.

Additionally, consider the hose’s age and material quality. Older hoses are more susceptible to wear, so replacing them with a robust, high-quality option can improve longevity and reliability. Always refer to your manufacturer’s specifications to find the right replacement.

Verifying Pump Performance Issues

Begin by examining the pump unit for leaks or signs of wear. Check all connections for tightness and ensure there are no visible cracks. Insufficient water flow can be attributed to a worn-out pump seal or damaged piston. If either part appears compromised, replacement is recommended.

Assessing Pressure Output

Next, determine if the unit is attaining its rated output. Use a pressure gauge to measure the output at the nozzle. If the reading is significantly lower than the manufacturer’s specification, further investigation is needed. Consult your user manual for the optimal pressure range.

- Inspect the unloader valve, which regulates the pressure. A malfunctioning valve can cause pressure fluctuations.

- Examine the supply of water; ensure that it meets the minimum flow rate required.

- Check for correct nozzle fitting as incorrect fittings can lead to inefficiencies in pressure delivery.

Understanding Pump Types

Familiarise yourself with the specific pump type in your unit–axial or triplex. Each has unique characteristics regarding performance and maintenance. Triplex pumps, known for their durability, may require specific lubricants. Failure to adhere to these can affect functionality.

- For axial pumps, inspect the cam for wear; a worn cam can hinder operation.

- Regularly clean or replace the air filter to ensure unrestricted airflow, which is vital for pump performance.

In summary, focus on these key aspects to evaluate and potentially restore pump functionality. Address any identified issues, and consider consulting a professional if uncertainty persists. Regular maintenance will prolong life and ensure optimum operation.

Assessing the pressure washer settings

Start by checking the nozzle type you’re using. Different nozzles deliver varying spray patterns and intensity; ensure you have selected one appropriate for your task. A low-pressure nozzle will disperse water less forcefully, while a high-pressure version is designed for tougher jobs.

Next, examine the pressure settings on your device. Some models have adjustable pressure controls. If it’s set too low, performance will be compromised. Adjust the dial to increase the force, making sure it’s in the recommended range for your specific cleaning requirements.

Also, consider the distance from the surface you’re cleaning. Standing too far away can reduce effectiveness. Maintain an optimum distance–typically around 30–50 cm–depending on the task at hand.

Lastly, check if the machine has a soap or detergent feature. If used incorrectly, it can interfere with the water flow. Ensure the detergent setting is off when you are aiming for a strong water stream, as mixing soap with high-pressure discharge can dilute performance.

Identifying issues with detergent use

Check the type and concentration of the detergent you are using. Some formulations require dilution, while others can be used straight. Ensure you’re adhering to the manufacturer’s guidelines for the specific product.

Inspect the detergent tank for clogs or blockages. A buildup of residue can obstruct the flow. Clean the tank and any associated tubing thoroughly to ensure an uninterrupted supply.

Verify that you are using the correct nozzle for detergent application. Certain tips are designed specifically to mix soap effectively. Using the wrong nozzle can hinder the proper delivery of cleaning agents.

Examine the mixing ratio. If you’re using a pressure model with a built-in detergent system, improper mixing may lead to insufficient soap reaching the surface being cleaned. Adjust the settings or proportions as necessary.

Testing for pump issues related to detergent

A malfunctioning detergent pump may not draw the chemical effectively. Listen for any unusual sounds during operation. If the pump seems to struggle, replacement might be required.

Ensuring compatibility with your machine

Lastly, make sure the detergent you use is compatible with your model. Certain mixtures can cause damage to components and affect performance. Stick with recommended brands to prevent issues.

FAQ:

What could be causing my pressure washer to lose power and not spray hard?

There are several reasons why your pressure washer might not be spraying hard. First, check for any blockages in the nozzle or hose. Dirt and debris can obstruct the flow and reduce pressure. Secondly, examine the water supply – insufficient water flow can lead to a drop in pressure. Make sure the water source is adequate and that hoses are not kinked. Additionally, consider the pump’s condition; if it’s worn out or damaged, it might not generate enough pressure. Lastly, ensure you’re using the correct nozzle for your task, as using a nozzle with too wide of an opening can lessen the impact of the spray.

How can I troubleshoot my pressure washer if the spray seems weak?

To troubleshoot a weak spray from your pressure washer, start by verifying the connection to the water supply and ensuring it is unrestricted. Next, inspect the filter and screen for any clogs that could hinder flow. Cleaning or replacing these components may help. Look at the spray gun and wand for leaks or damage, as these can also contribute to loss of pressure. If your machine has adjustable pressure settings, make sure it is set correctly. Additionally, check that the pump is functioning properly; some pumps require regular maintenance to avoid issues. If you’re still experiencing problems, consulting the manual or contacting a professional may be necessary.

Is it possible that the nozzle I’m using is affecting the pressure of my washer?

Yes, the nozzle you are using can significantly affect the pressure of your pressure washer. Nozzles come in different sizes and shapes, which dictate the spray pattern and pressure. For instance, a wider nozzle allows more water to flow but with less force, which can result in the weak spray you might be experiencing. Conversely, a narrow nozzle concentrates the water flow, increasing pressure and effectiveness. Make sure to select the appropriate nozzle for the cleaning task at hand. If you’re unsure, refer to the pressure washer’s manual for guidance on which nozzle is recommended for optimal performance.