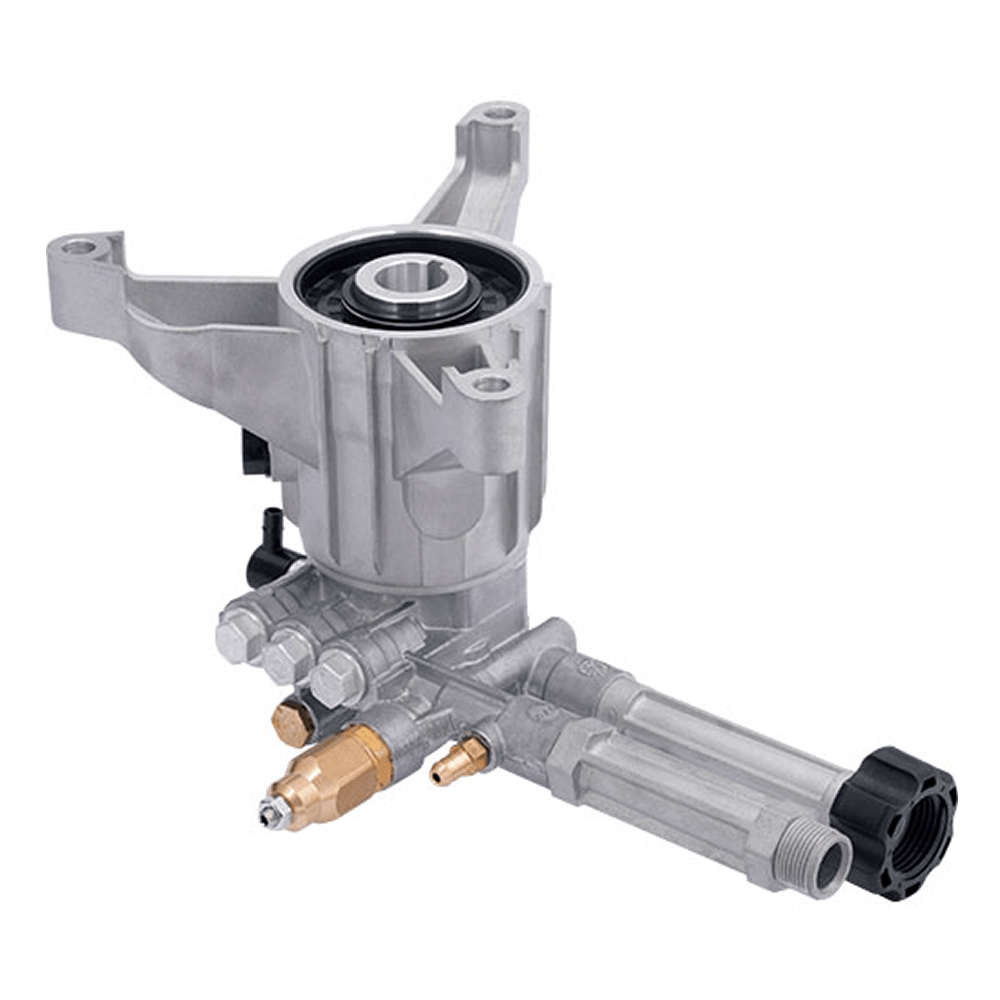

In this article I talk about how pressure washer pumps work, the types of pumps, and where you can shop for a replacement pump if you need one.

Power cleaner pumps are the main components in a hi psi washing system, and hence have to be chosen with care, and according to your unique requirements. You should certainly look at the type and quality of the pump on a washer before you buy it. You want something that is durable and is going to last for many years. The same goes if you need to replace a broken pump, which can be a lot cheaper than going out and buying a whole new washer.

The pump is responsible for delivering an exact amount of pressure to the water, and to control the flow rate of that water. The efficiency and speed of a cleaning job will depend on these two functions.

How Pump Power Is Measured?

The pressure (measured in PSI or pounds per square inch) provides the power or force needed for the cleaning process, and the flow rate (measured in GPM or gallons per minute) delivers the required volume of water. The higher GPM the faster you’ll be able to clean a surface. Multiplied together PSI and GPM form cleaning units or CU, which is a measure of the overall cleaning power of your power washer. You can read more about these measures in my article on Picking the Best Pressure Washer for the Job.

When the pressure is high, and there is more volume of water, the cleaning process will be faster and more efficient. However, the amount of pressure needed has to be decided according to individual requirements. For instance, for home cleaning purposes, where the surfaces are relatively delicate and the dirt is not so deeply entrenched, a pressure of 1,500 to 2,000 PSI should suffice. Higher pressures are likely to peel off paint, and damage wooden surfaces by splintering the edges. However, for cleaning barnacles from the hull of a boat, or cleaning plain concrete surfaces, or even cleaning large decks that are very dirty, more pressure is required.

Higher levels of pressure starting from 3,000 PSI and going up are generally required for industrial or commercial applications, where the dirt and grease is quite deeply entrenched. Depending on the type of cleaning, the pressure requirement can go up to as much as 10,000 PSI for certain industries. Secondly, industrial grade washers also require a higher flow rate to rinse out the dislodged dirt, particularly on vertical surfaces.

This video shows how a pressure washer pump works by looking at the inside of a cutaway half of a washer.

Power Types

Power cleaning systems are powered by electricity, gas, or diesel. Electrical motors are more suited for home use because they are not as powerful as gas or diesel models. Gas and diesel can be used at home too, as well as for commercial and industrial applications. Whichever fuel type you choose will not affect the efficiency of the pump in any way. Pumps powered by different fuels deliver the same pressure and flow rate according to their individual specs.

Apart from selecting the right combination of pressure, flow rate and power type, you also have to consider the construction of pressure washer pumps. They are mainly categorized into two types, axial cam or direct drive pumps and triplex plunger pumps. Each type has its set of advantages and disadvantages. Here is some important information on each that will help you make an informed decision.

Direct Drive Pumps

This pump is directly connected to the engine of a washer, hence the name. Direct drive pumps are also called wobble pumps or axial cam pumps. The direct connection provides a faster spin, and there are lesser moving parts resulting in minimum maintenance, and increased reliability. These pumps are cheaper to manufacture, and are quite popular in pressure washers. However, they are not suitable for consistent use, as they wear out faster, and have a shorter life span. If your usage exceeds 30 hours of cleaning in a year, you should consider the other two types of pumps.

Belt Drive Connection

As the name suggests, a CAT belt connects the pump and the engine shaft. This results in a lower RPM compared to direct drive pumps. The indirect connection dissipates vibrations and lowers heat, thus decreasing the wear on major components, extending its life. Lesser vibrations make the pump operate more silently compared to other types. This type of pump connection is ideal for consistent use, and is a popular choice for industrial applications, where the usage is more than 20 hours a week.

Although this pump connection causes less wear on major components, the belt will have to be replaced frequently, increasing the maintenance. Secondly, the maintenance tasks are not easy or straightforward, as the inner mechanism is quite complex. They are also quite expensive compared to direct drive models, but they are more cost effective due to their longer life span. These pump connections are often seen at car washes, and industrial grade pressure cleaning systems in addition to being placed in cordless pressure washers.

Triplex Plunger Pumps

Triplex plunger pumps are sturdier than axial cam pumps. They last much longer because they are not connected directly to the engine and therefore are not as subject to as much force and wear and tear. They have three plungers that offer a smooth flow of water with very little pulsing. They can obtain very high levels of pressure and are ideal for commercial and industrial uses. Triplex plunger pumps can be connected to the engine through either a belt drive system or gear box drive system.

Gear Box Drive Connection

In this type the pump is directly connected to the motor shaft through a gearbox. This gearbox lets you reduce the RPM of the pump as per the requirements of the job at hand. These models are available in many different power level configurations, and hence they can be selected for specific requirements.

The control of the RPM enables the user to lessen the wear on the machine, thus extending its life. The downside of these pumps is their bulk and heavy weight, making them less portable. Also the mechanism of the gearbox increases the complexity of the machine, making it hard to repair and maintain.

Buying A Replacement Pump

If you are shopping for a replacement pressure washer pump then you’ll need to find a model that matches specifically to the PSI, GPM, and gas engine flange connection size (typically 3/4 inch or 7/8 inch) of your existing pressure washer. If you want to upgrade your psi or gpm with a more powerful pump you can do so but only if your washer parts like the wand, hose, tips, and other accessories are rated for the increased power of the new pump.

Often the best place to look for replacement parts like a pump is on the manufacturer’s website. Or you can simply call the customer service number listed in your owner’s manual. There are also high quality generic pumps out there that will fit many different washer makes and models. These pumps are generally much cheaper than brand name pumps you’ll find from the manufacturer. One top pump manufacturer is AR (Annovi Reverberi) Blue Clean, which has many highly rated pumps for a variety of different washers. Other manufacturers include CAT, Comet, Giant, and General Pump.

A lot of washer pumps can run you £150 to over £200 for an axial cam pump to £300 to £600 for a triplex plunger pump, so you want to find the best price you can. Click here to search for pressure washer pumps on Amazon.

Conclusion

The selection of a pressure washer pump will mainly depend on your cleaning requirements and budget. It will also depend on whether you are buying a new washer or looking for a replacement pump for your existing washer. Remember direct drive axial cam pumps have a cheaper price tag, and are light to move around, but are not built for heavy usage, and have short life span. Triplex plunger pumps are sturdier and longer lasting but much more expensive than axial cam pumps and built for consistent industrial or commercial use or frequent residential applications.