If you want to reliably clean surfaces of loose and solid deposits, then sandblasting is the ideal method. However, you do not have to use industrial sandblasting equipment.

In this respect, we would like to introduce you to sandblasting with a pressure washer. A pressure washer can be operated very well with a blasting medium.

Find out which components you need, what the differences are between sandblasting and wet blasting and what you can use such an upgraded high-pressure cleaner for.

5 Best Pressure Washer Sandblasting Kits

Pressure Washer Sandblasting Kits

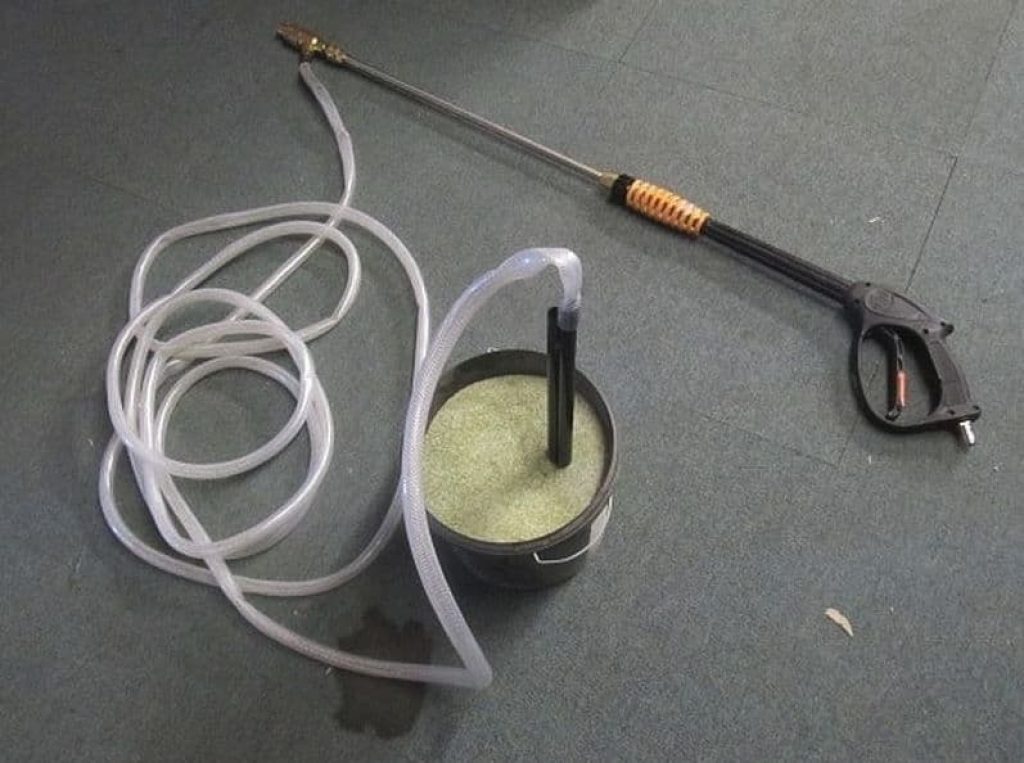

The utensils you need for pressure washer sandblasting

You will need:

- Recommended pressure washer with 420 l/h & 110 bar.

- Suitable sandblasting attachment for the high-pressure cleaner (pay attention to the min. power specification)

- Blasting material suitable for the sandblasting attachment (size of grain)

- Suitable protective equipment / face and eye protection is essential!

First of all, you should look for a solid and high-quality pressure washer.

There are many brand manufacturers, such as Karcher, Nilfisk, Wilks, Ryobi, Bosch, etc., which are suitable for a wide range of cleaning tasks.

When choosing one, however, you should make sure that it has a high working pressure of at least 110 bar.

It is also recommended to choose a pressure washer with a flow rate between 360 and 500 l/h.

Of course, the sandblasting attachment is particularly important. This component is available either from the same manufacturer of the pressure washer or from various third-party suppliers.

However, you should make sure that the attachment is also designed for your pressure washer. When buying the sandblasting attachment, however, it depends on the grain size that can be used with the attachment.

Here you should again pay attention to the working pressure in bar as well as the delivery rate in l/h. Only if the specifications of the blasting attachment match those of the pressure washer or remain within the limits can you work efficiently with it.

As a further accessory, you will of course need the actual abrasive. You can choose between a grain size of 0.2 and 0.8 mm. In the beginning, it is better to use the coarse-grained blasting media with 0.8 mm.

These can be bought cheaply in DIY stores. Otherwise, any normal sandblasting medium can be used.

Also put on the necessary protective clothing for wet blasting. This includes protective gloves, protective boots and definitely face/eye protection!

The blasting medium for wet blasting

After you have prepared your pressure washer, you can start wet blasting. Besides the aforementioned coarse-grained garnet sand, there are many other blasting media designed for different surfaces.

It is therefore important to take a closer look at these materials. You must pay attention to the hardness, grain size and shape of blasting media.

The hardness

A hard blasting material ensures a higher material removal rate with sufficiently high pressure. The surface to be processed is roughened more. There is a so-called Mohs or Rockwell scale for the hardness, which you can use as a guide.

The grain size

The larger the diameter of an abrasive grain, the higher the impact force on the surface to be processed. It is important that a blasting material always corresponds to the same grain size so that an even removal and roughening of the surface is achieved.

The shape

An important distinguishing criterion is the shape of the blasting material. A round grit produces an efficient cleaning effect over the entire surface. The surface is not particularly damaged or attacked.

A sharp-edged, splintery grain has a cutting or scraping cleaning effect. The surface of the material is roughened more deeply. This may be desirable if the surface is to be prepared as a primer.

A compact, angular or edge-rounded grain achieves a scraping and simultaneously smoothing cleaning effect. The surface is not roughened as deeply.

The most popular blasting media

There are many different abrasives, ranging from aluminium, wire grit, aluminium oxide, polycarbonate to cast steel. However, the most popular for wet grinding are: copper slag, aluminium and glass beads.

Copper slag

Copper slag achieves a medium hardness and is extremely sharp-edged. This results in good material removal. It is very suitable for removing old paint, varnish and rust adhesions.

Aluminium

Aluminium is known for its high cleaning effect. An advantage is that the relatively light aluminium balls can also be used on thin-walled materials without deforming them due to the pressure. With aluminium you can clean safely without material embrittlement.

Glass beads

In contrast to glass granulate, glass beads are round and are ideal for chemically neutral surface cleaning. The surface is not attacked as deeply and the sandblasting equipment is also spared by their use. Glass beads can be used without any health risks.

Disposable and reusable blasting material

Many people ask themselves whether a blasting material can be used more than once. In the case of disposable blasting material, it is assumed that it is contaminated after the cleaning process or after being sprayed onto the surfaces to be cleaned and therefore cannot be reused.

However, there are also reusable blasting materials that can be used repeatedly. However, this is only possible in professional blasting chambers where the abrasive can be returned to the system after use.

Normally, a reusable abrasive cannot be reused in wet blasting. If it is sprayed onto the surface, this usually happens outside. It is hardly possible to collect it there.

However, if you sandblast with your high-pressure cleaner in a partitioned chamber, you can sweep the material back together.

With the help of a sieve that corresponds to the appropriate abrasive grain size, you can reuse a multi-blast material. In this case, it is advantageous to use a coarser grain size. Each time you sandblast, the diameter decreases. In this way, you get a finer grain size from a coarse grain size over time.

Fields of application: Pressure washer sandblasting

Wet blasting with a pressure washer is mostly used when surfaces need to be freed from rust and old paint residues. However, you can also use it to efficiently clean facades and walls. Perhaps you also need to remove graffiti from an exterior wall.

For efficient cleaning, you should pay attention to the power of your pressure washer, but also to the blasting agent used. Since wet blasting does not damage the surface as much as dry sandblasting, you can also use it to optimally clean engines, equipment and even bicycles.

However, you should always make sure that a round or rounded abrasive is used in this case. This does not roughen the surface too much. Of course, you can also use it to reliably clean your patio.

This is always appropriate when the hard water jet of your pressure washer does not provide sufficient cleaning. Another application is the removal of mould. Even in hard-to-reach places, these pollutants can be removed from walls and ceilings.

Sandblasting VS Wet blasting

If, for example, you want to remove rust or other strongly adhering contamination from surfaces, a conventional pressure washer with a water jet is usually not sufficient. The most effective method is sandblasting. The procedure is quite simple.

In sandblasting, a special blasting material is sprayed at high pressure onto the surface to be treated. The pressure of the blasting material causes sufficient friction on the surface so that it is absolutely clean afterwards.

For pressure washers, for example, garnet sand is used. This sands the surface smooth and clean, similar to manually moved sandpaper.

Classic sandblasting requires a compressor and a sandblasting unit. The abrasive is transported to the surface with the help of a sandblasting gun as an abrasive. The strength of the impact force and ultimately the sandblasting result depends in turn on the working pressure. Sandblasting can cause a high dust load.

Another alternative is wet blasting. For this, you can use a conventional pressure washer that has a sandblasting attachment. The actual abrasive is transported to the material surface with the help of water pressure. The impact force of the blasting and abrasive material is much lower than with a compressed air-driven sandblasting unit.

The advantage of wet blasting is that there is virtually no dust formation. In addition, the lower working pressure means that the material surface is not so badly affected. Even if the cleaning result is somewhat lower, a gentler cleaning can be achieved. However, you should also note that removing wet abrasive is somewhat more time-consuming.

Required protective equipment: Pressure washer Sandblasting

The abrasive is also thrown out of the nozzle with a pressure washer using very high water pressure. Therefore, the small particles can get onto the skin or into the eyes. Possible injuries cannot be ruled out in this case.

To ensure that you are well equipped to use your pressure washer for sandblasting, we recommend that you wear protective goggles and work gloves.

If you also want to remove harmful substances, such as mould, then you should also wear a respiratory protection mask, such as an FFP2 mask.

.jpg)